Background

Until the 1960s nearly all cookware in most households around the world was either cast iron, copper, or stainless steel with no coating on the cooking surface. This began to change in 1954 when Marc Gregoire, a Frenchman, applied a coating which contained a substance called PTFE on a pan.

The rise of Teflon

The new coating, called Teflon, became a worldwide hit among consumers who wanted a more hassle-free, easy-to-use cookware item. In western society Teflon became a household word, so well-known that it was given as a nickname to politicians who seemed able to survive any disaster with their reputations unblemished – for example Tony Blair was known as ‘Teflon Tony’.

However, the Teflon brand’s credibility (like Tony Blair’s political career) began to suffer in the late 90s when it was found that if the coating was applied under too much heat the PTFE, which provided the non-stick release in the coating, would breakdown and emit toxic fumes which would kill birds and possibly be damaging to human health. There were also complaints that the coating would peel off after extensive use.

The emergence of ceramic coatings

Therefore, in the late 00’s coating manufacturers, such as Greenpan and Whitford, began to develop ceramic coatings, which were seen as a healthier alternative to Teflon because they contained no PTFE. At first ceramic coated pans were a huge success, because not only were they seen as a healthier alternative to PTFE-based coatings, but they also looked very attractive with their cream and white colour.

However, after intensive use by various customers all over the world it was soon discovered that although ceramic coatings didn’t have any health concerns, they were affected by some serious quality control issues. The biggest difficulty with ceramic coatings was that after sustained use the silicone oil inside the coating would dry out and the non-stick effect would become redundant. Customers were therefore paying for cookware utensils with a non-stick release which would not, in some cases, last longer than a year. In addition, it was also discovered that the colour stain and scratch resistance of ceramic coatings was not as good as previously thought.

Stone-finish cookware

Some cookware manufacturers responded to this by producing items with a stone finish. Although these cookware items still contained some PTFE, they at least had a stronger, more durable appearance than lightly coloured ceramic coatings. And yet, although these new coatings did appear to have a stronger construction, the stone finish was misleading, because they were not metal utensil-safe and, like every other non-stick coated cookware, intense use eventually degraded the coating, either wearing it away or reducing the non-stick release.

What next?

So by early 2013 there was a significant gap in the market: consumers wanted a high quality cookware item without possible health concerns (such as those associated with PTFE), a non-stick effect that would last for at least a few years (unlike ceramic coatings), and a pan which didn’t just look scratch-resistant but really was metal utensil-safe.

It is for this reason that the popularity of Lotus Rock cookware has risen exponentially in the last couple of years. As you can see from the table below Lotus Rock has various advantages, all of which either match or exceed the existing competition in the market place.

|

PTFE coating |

Ceramic coating |

Stone-finish coating |

Lotus Rock coating |

|

|

Durable non-stick release? |

Good |

Poor |

Good |

Excellent |

|

Health issues? |

Yes |

None |

Yes |

None |

|

Scratch resistance? |

Poor |

Ok |

Good |

Excellent |

Lotus Rock cookware is now sold in all 6 continents of the world, from the USA, to Venezuela, to various European countries such as the UK, Italy and Turkey, to South Africa, Australia and Hong Kong. There are various reasons for this sudden popularity, but one of them is the natural, non-toxic, durable non-stick release.

Why does Lotus Rock have such a unique, long-term, and effective non-stick effect?

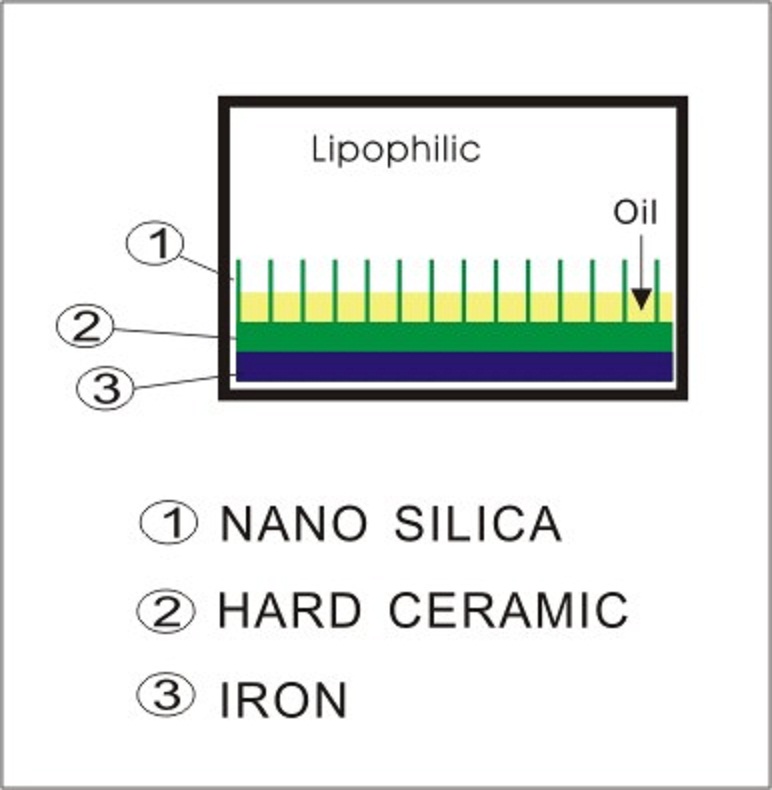

All Lotus Rock items contain a thin layer of nano-silica, which is lipophilic (fat-loving). This coating, which rests on top of a thick ceramic layer, is permeable to cooking oil. At the beginning of the cooking process the consumer must add cooking oil which then infiltrates the surface of the cookware.

By permeating the surface of the cookware the oil is able to rest inside the nano-silica, thus creating a natural, long-lasting non-stick release which, unlike all other general coatings, won’t significantly worsen over time. Thus by the simple act of adding oil before cooking the customer creates a physical non-stick surface, perfect for a high-quality cooking experience – similar to cooking on uncoated cast iron, except that with Lotus Rock no re-seasoning is needed, so the customer need not worry about rust.