Background

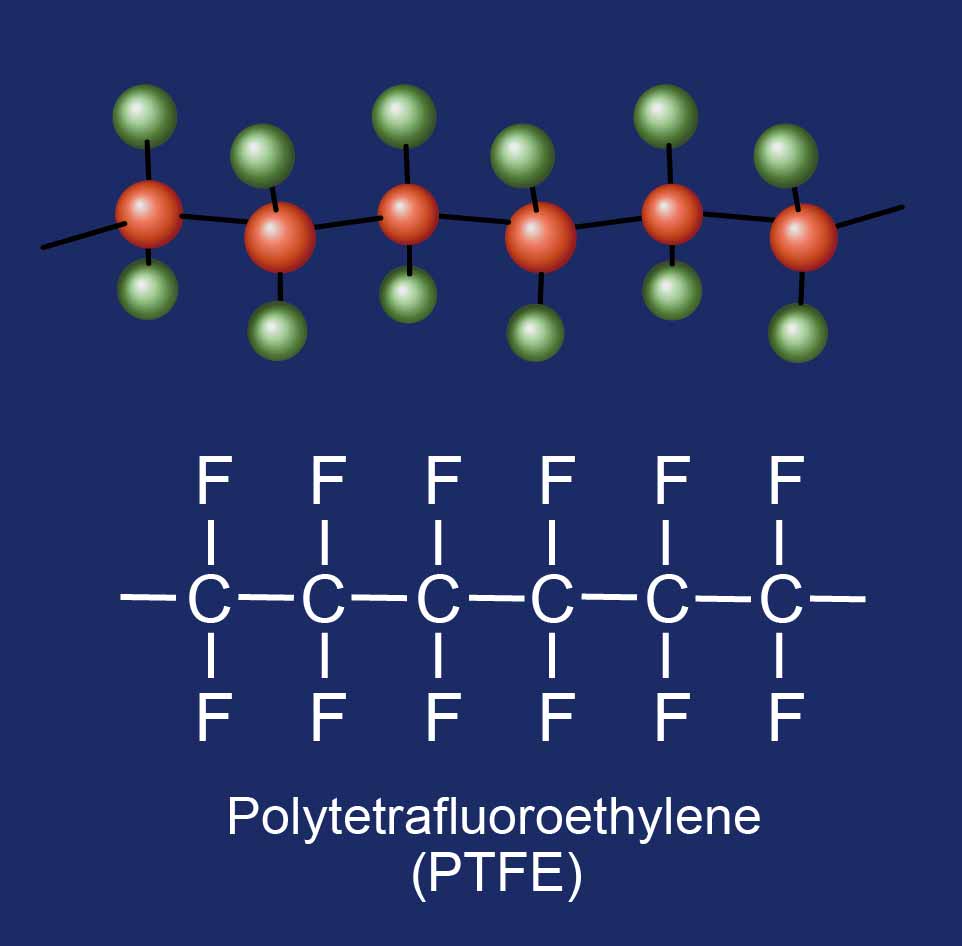

Until the 1960s nearly all cookware in most households around the world was either cast iron, copper or stainless steel, with no coating on the cooking surface. This began to change in 1954 when Marc Gregoire, a Frenchman, applied a coating which contained a substance called PTFE (polytetrafluoroethylene) to a pan.  This substance contains fluropolymers, which even to this day have been proven to have the lowest coefficient of friction (CoF) of any known solid. In other words, the majority of materials (in this case foodstuffs) do not stick to it. This highly significant breakthrough in non-stick technology would have far-reaching consequences because today three quarters of all cookware utensils use a non-stick coating containing fluropolymers.

This substance contains fluropolymers, which even to this day have been proven to have the lowest coefficient of friction (CoF) of any known solid. In other words, the majority of materials (in this case foodstuffs) do not stick to it. This highly significant breakthrough in non-stick technology would have far-reaching consequences because today three quarters of all cookware utensils use a non-stick coating containing fluropolymers.

From the 1960s onwards this new PTFE-based non-stick coating was adopted by a company called DuPont, who gave it the brand name Teflon. It became a worldwide hit almost immediately among consumers who wanted a more hassle-free, easy-to-use cookware item. Unlike cast-iron or copper, Teflon didn’t need to be seasoned or continually re-polished, and in contrast to stainless steel, a large quantity of oil didn’t have to be used each time to stop items with a high protein content, such as eggs, poultry and fish, sticking to the pan.

PFOA

However, the Teflon brand’s credibility began to suffer later in the 20th century when it was found that a substance called PFOA (Perfluorooctanoic acid), which was used in the Teflon coating as an emulsifier to help the PTFE spread evenly on the pan surface, had serious health issues for human beings. The negative publicity forced Dupont to remove PFOA from the Teflon formula, replacing it with another emulsifying substance, still unknown even today.

PTFE

At the turn of the 20th century controversy over PTFE non-stick coating continued as some medical experts produced reports which claimed that if it was heated to above 350 degrees then toxic fumes would be emitted and that these would be lethal to birds. These findings also led some to believe and suspect that these toxic fumes could be hazardous to humans as well.

In addition to health concerns, the PTFE non-stick coating was also later found to have cooking performance problems. One of the obvious benefits of a PTFE non-stick coating is the fluropolymers which, as Marc Gregoire had earlier found out, are extremely stick-resistant to other substances around it. However, there is a flip-side to this benefit: within a coating PTFE does not bond well to itself, which means that this type of coating has a pinhole problem. This is a particular concern when oil is heated on the pan to a high temperature, as the oil molecules decrease in size and can then penetrate the coating. This can not only cause corrosion problems, but can also lead to the coating breaking up and peeling off – thus also impairing the quality of the non-stick release.

Lotus Rock

Lotus Rock, on the other hand, has a natural, durable non-stick release which contains no PFOA or PTFE. Because it has no PTFE all Lotus Rock pans have excellent heat and scratch resistance. A Lotus Rock pans can be heated to over 350 degrees with no chance of any toxic fumes being emitted from the surface of the coating.

Lotus Rock, on the other hand, has a natural, durable non-stick release which contains no PFOA or PTFE. Because it has no PTFE all Lotus Rock pans have excellent heat and scratch resistance. A Lotus Rock pans can be heated to over 350 degrees with no chance of any toxic fumes being emitted from the surface of the coating.

Metal utensils, such as spatulas or knives and forks, can all be used on the surface of the coating without any chance of scratching the coating and making it peel off. Moreover, because all Lotus Rock pans have an extremely thick, solid ceramic interior, up to 100 microns, they have, unlike PTFE non-stick coatings, no pin-hole or peeling off related difficulties.

Metal utensils, such as spatulas or knives and forks, can all be used on the surface of the coating without any chance of scratching the coating and making it peel off. Moreover, because all Lotus Rock pans have an extremely thick, solid ceramic interior, up to 100 microns, they have, unlike PTFE non-stick coatings, no pin-hole or peeling off related difficulties.