As noted previously here, all Lotus Rock pans have an excellent high heating effect, a desirable quality which helps produce delicious tasty food. What thermal properties give a cooking utensil an excellent heating effect? Well, first, the pan must heat up quickly when placed on the heat sources; second, it has to be thick enough to heat up evenly across its surface; and third, it needs a large enough thermal capacity to minimise loss of heat when food is added to the pan.

Let’s start with the Lotus Rock pan’s prompt response to heat. Although carbon steel does not heat as evenly as aluminum, it does heat up much more quickly. Some methods of cooking require the pan to have reached a certain temperature before it is used; for example, browning, which is best done on a pan with a temperature of 180 degrees (this is the temperature when the Maillard Reaction begins to take effect). If an impatient cook starts before the pan reaches this temperature then the meat or vegetables being seared might still be browned but will have lost a large amount of moisture, making it dry and un-appetizing.

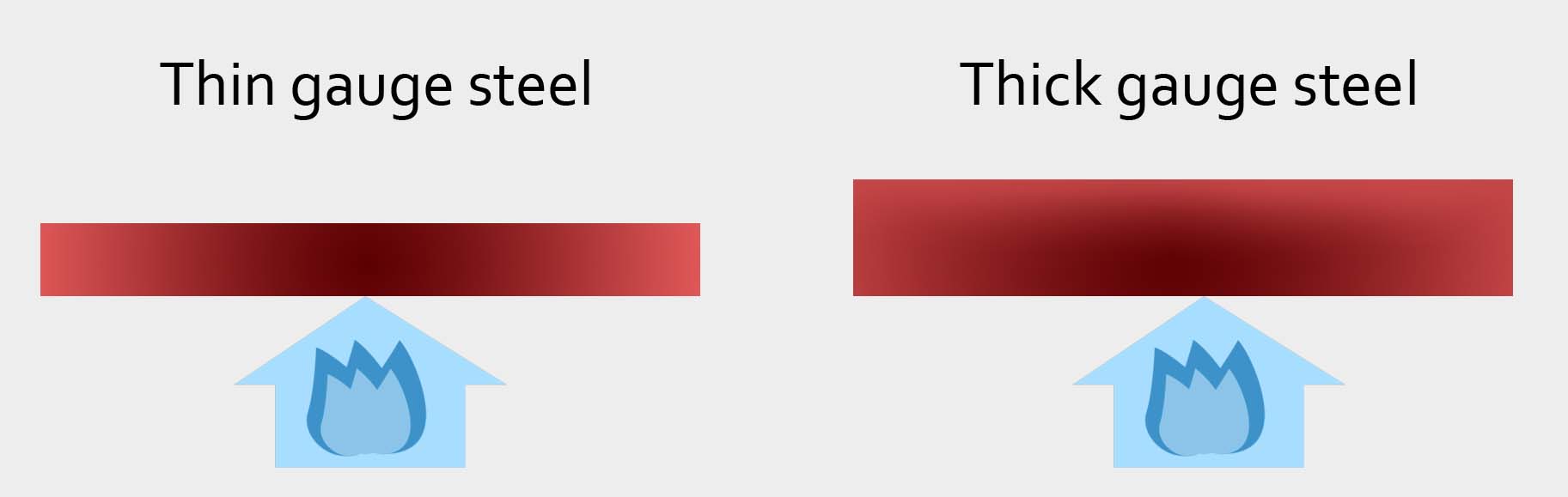

However, although carbon steel heats up quickly, a thin gauge of steel will do so unevenly, heating up most quickly in the centre of the pan. This not only creates a hot spot, causing uneven cooking, but will eventually warp the pan and give it a convex shape, causing oil and other liquids to slide to the edges. In order to disperse the heat more evenly around the pan all Lotus Rock pans are made with 2.0mm gauge steel. As is shown in the diagram below, a thicker gauge broadens the area at which the heat reaches the surface of the pan.  So with carbon steel as its substrate Lotus Rock pans can not only heat up very quickly but can also, due to the steel’s thick 2.0 gauge, provide a more dispersed heating effect so that the food is cooked evenly. It thus meets the first and second criteria for an excellent high heating effect. What about the third criterion? What happens to the heating effect of a Lotus Rock pan when food is added?

So with carbon steel as its substrate Lotus Rock pans can not only heat up very quickly but can also, due to the steel’s thick 2.0 gauge, provide a more dispersed heating effect so that the food is cooked evenly. It thus meets the first and second criteria for an excellent high heating effect. What about the third criterion? What happens to the heating effect of a Lotus Rock pan when food is added?

If you were to compare all the main metals for cookware usage, you would find that carbon steel is among the most dense (three times more dense than aluminum, for example), and as we know, Lotus Rock has a very heavy carbon steel gauge. This extra mass and space in its substrate means a Lotus Rock pan has a high heat storage capability, an essential component for an excellent heating effect. When a steak is placed on a grill pan to impart that smoky, chargrilled aroma, or a large quantity of vegetables are quickly added to a stir wok, the high thickness and density of a Lotus Rock pan will minimiss heat loss. So instead of steaming in their own juices, the steak and vegetables will sizzle and heat up quickly and evenly for a delicious and crispy taste.

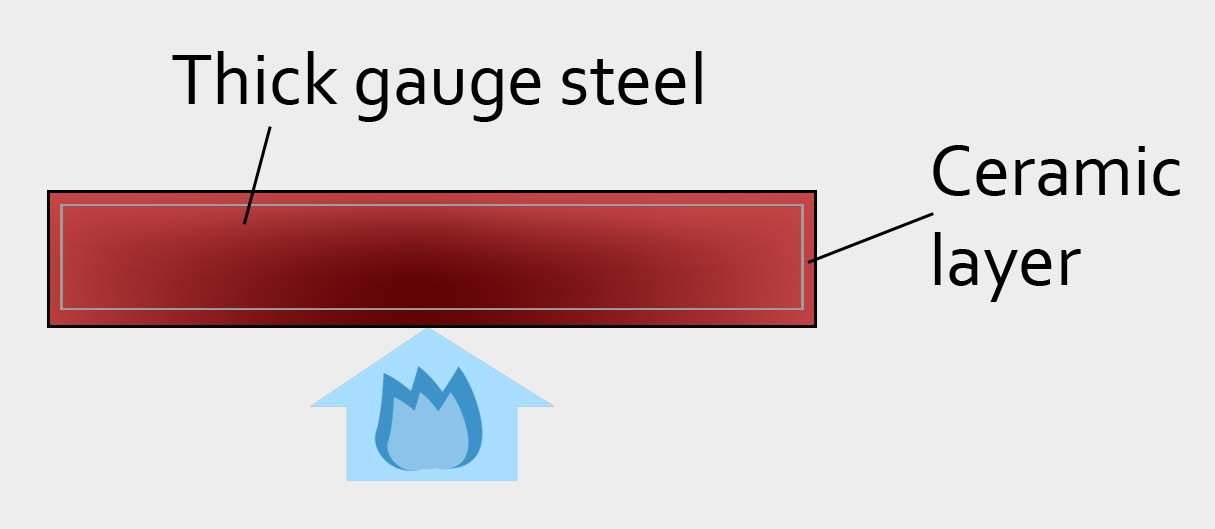

A second factor facillitating heat retention is the thick layer of ceramic on both the interior and exterior of all Lotus Rock pans. Most coatings on cookware sold throughout the world today have a thickness between 15-30 microns; the ceramic layer on Lotus Rock pans is in contrast around 100 microns thick. This thick coating increases the heat retention capability of all Lotus Rock pans due both to its extra mass and poor heat conductivity. Ceramic does not conduct heat very well, but it is good at storing heat – this is why it is often used for oven dishes.  So when food is added to an already well heated Lotus Rock pan the temperature should not drop significantly, in part because of the heavy gauge carbon steel substrate but also because of the thick ceramic layer on both the interior and exterior of the pans. Thus the very thick material of a Lotus Rock pan is perfect for high heat cooking methods, such as for sautéing, searing, grilling and stir frying.

So when food is added to an already well heated Lotus Rock pan the temperature should not drop significantly, in part because of the heavy gauge carbon steel substrate but also because of the thick ceramic layer on both the interior and exterior of the pans. Thus the very thick material of a Lotus Rock pan is perfect for high heat cooking methods, such as for sautéing, searing, grilling and stir frying.