May 27, 2015 / arnoldtnn / 0 Comments

As was explained in the previous blog post, the sharp, protruding edges of a gas stove require a high quality cooking utensil to have a tough, strongly constructed outer coating to withstand chipping and highly visible scratch marks. However, cooking on a gas stove also necessitates a high quality handle because often the flame from the gas stove can, in certain cases, reach up the side of the pan and come into contact with the handle. This would be especially the case for high heat cooking methods, such as stir frying, or making a delicious, crispy crepe (all of which a Lotus Rock pan is very suitable for doing).

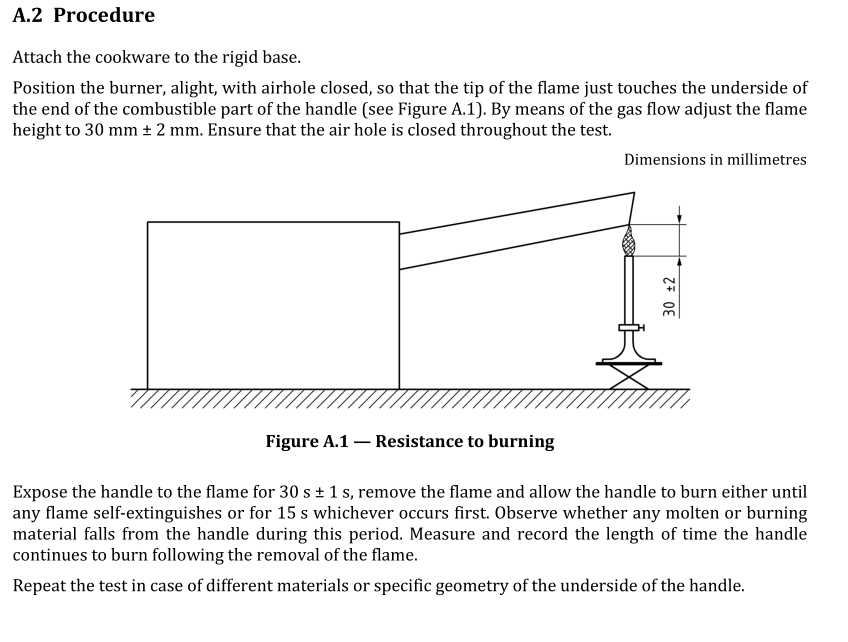

The kitchenware industry commonly uses a test, from BS EN 12983-1 2023 cookware standard regulations, to assess how flammable the material of a handle is to a candle flame set underneath it. For a pass to be awarded no visible sign of molten or burning material should have melted or dripped off the handle, after it has been heated for 30 seconds. In addition, once extinguished the handle material should not spontaneously re-ignite.

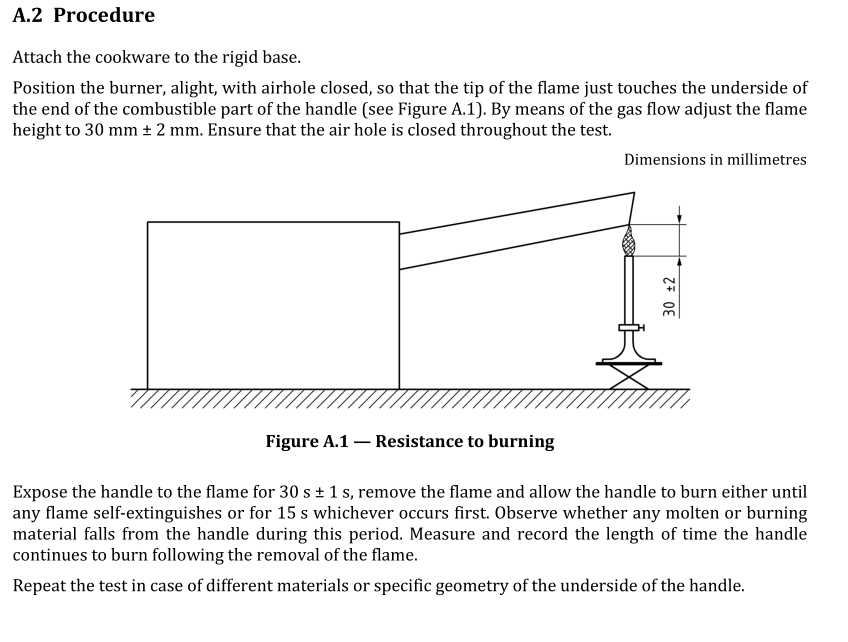

BS EN 12983-1 2023 Handle Resistance To Burning Test Procedure

Resistance to burningThe underside of the handle or any insertor inlay there, consisting of organicmaterial, shall not driymolten material orkeep burning when tested according toAnnex A. Any burning shall selfextinguishwithin 15 s of the removal of theflame. once extinguished the handlematerial shall not spontaneouslre.ignite.Each material shall be tested at itsposition.

The handle resistance to burning test procedure, according to BS EN 129831-:2023, is as follows: Step 1=Attach cookware to the rigid base.Step 2 = Position the burner, alight.with airhole closed, so that the tip ofthe flame just touches the undersideof the end of the combustible part ofthe handle. By means of the gas flowadjust the flame height to 30mm +2mm. Ensure that the air hole is

closed throughout the test. Step 3 Expose the handle to theflame for 30 s + 1s, remove the filameand allow the handle to burn eitheruntil any flame self-extinguishes or for 15 s, whichever occurs first. observe whether any molten or burningmaterial falls from the handle duringthis period.Step 4- Measure and record thelength of time the handle continues toburn following the removal of the flame.

Evaluation

On 15th on 15thJanuary 2025, in an Actontesting laboratory, the Lotus Rockbakelite Titlis handle passed theabove resistance to burningtest.This handle, , along with many others designed and patented by Lotus Rock, is safe to use over agas stove for numerous high heatcooking methods. Whether movinga crepe pan sideways to get the mixture spread around the pan for a delicious, crispy texture, or to quickly toss vegetables and thinly cut pieces of meat inside a stir wok, a Lotus Rock pan has the handles which are safe and non-flammable to do this.

May 26, 2015 / arnoldtnn / 0 Comments

A previous blog post described how a migration test can be done to test the surface reactivity of a cookware pan. The benefit of a non-stick coating on a pan is that it contains a substance called PTFE, which has very low reactivity with substances in contact with it. Even to this day, PTFE has been proven to have the lowest coefficient of friction (CoF) of any known solid. In other words, the majority of materials do not stick to it. Therefore, because of its excellent non-stick release and low reactivity to substances in contact with it, a PTFE-based non-stick coating should pass a standard BS EN 1186-1: 2002 migration test quite easily.

However, although PTFE does undoubtedly provide excellent non-stick release and low reactivity for a coating on a cookware utensil, it does have some significant disadvantages; one of these is a tendency of a PTFE-based non-stick coating to peel off. Within a non-stick coating PTFE does not bond well to itself, which means it can have a pinhole problem. This difficulty can be exacerbated not only through general scratching with a utensil and rubbing with a cleaning pad, but also when oil is heated on a pan to a high temperature for high heat cooking methods, such as stir frying or sautéing etc. For these types of high heat cooking methods, the molecules of cooking oil can decrease in size quite rapidly and then penetrate the highly porous PTFE coating. This can lead to the coating breaking up and peeling off – thus not only impairing the quality of the non-stick release but also creating a safety hazard as bits of the coating mix with the food on the pan.

One method to determine the resistance of non-stick coatings to separation from substrates, such as aluminum or steel, is to utilize a tool by cutting a right angle lattice pattern into the coating, penetrating all the way to the substrate. This is called the Cross Cut Adhesion Test, otherwise known as ISO 2409-2013. Some coatings may have a multi-layer system, and so this test can also be used to determine the resistance to separation of different layers from one another.

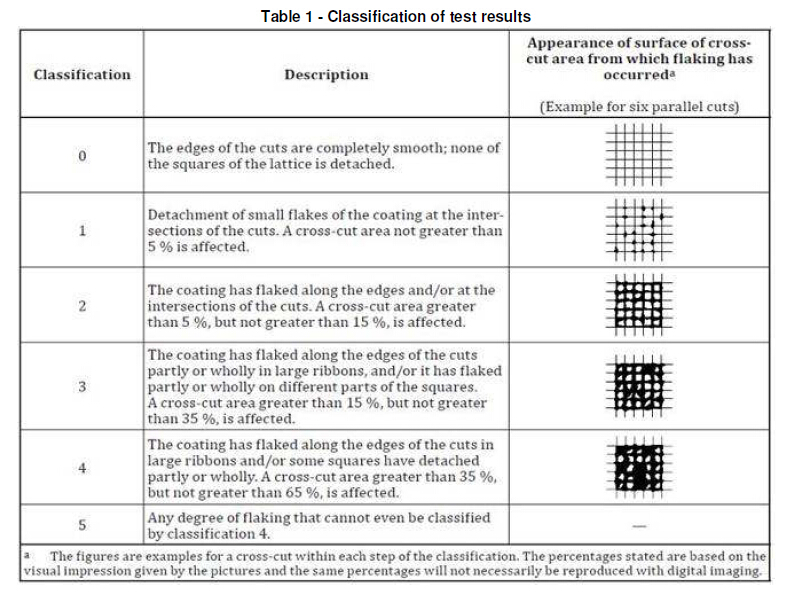

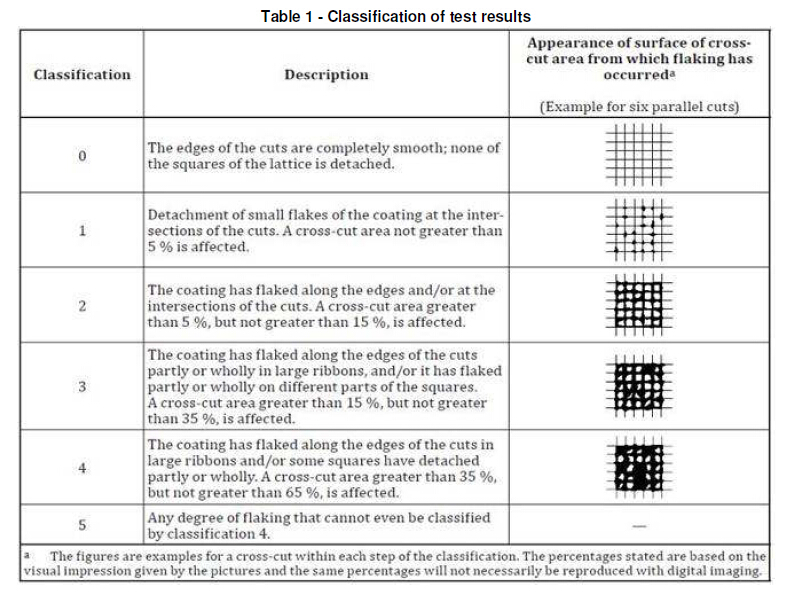

The below table are the classification of test results for an ISO 2409-2013 Cross Cut Adhesion Test.

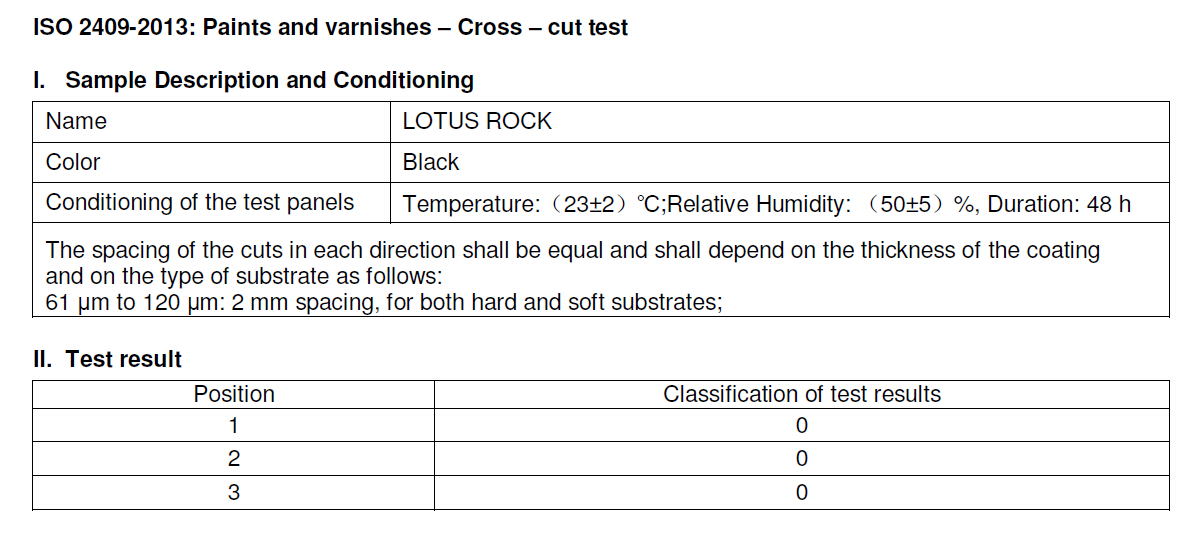

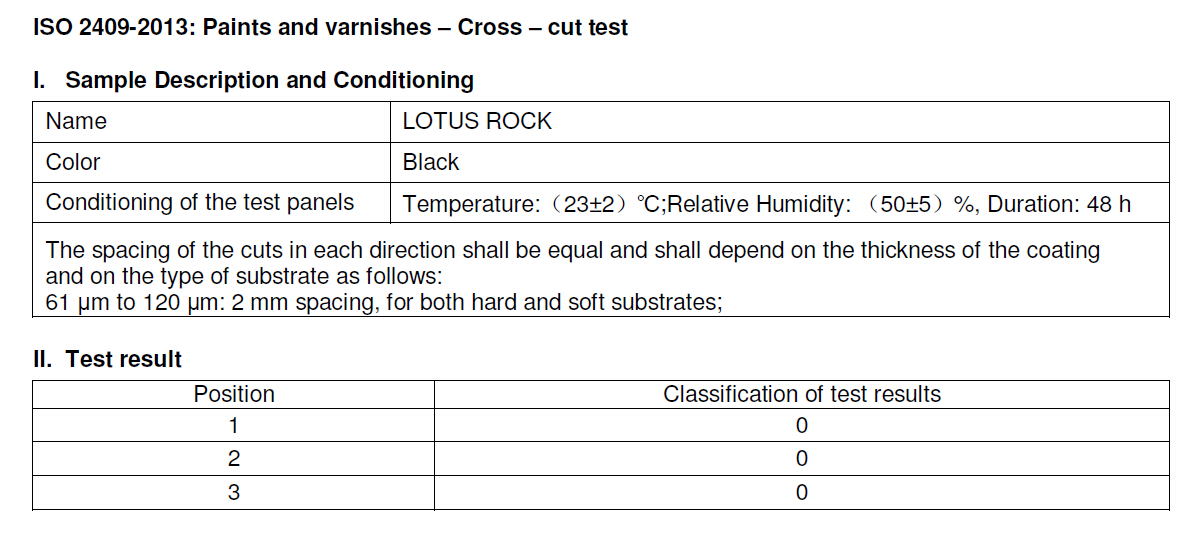

An ISO 2409-2013 test was conducted by SGS testing services, from 16th January 2015 to 21st January 2015, on a Lotus Rock frying pan. The test result was as follows.

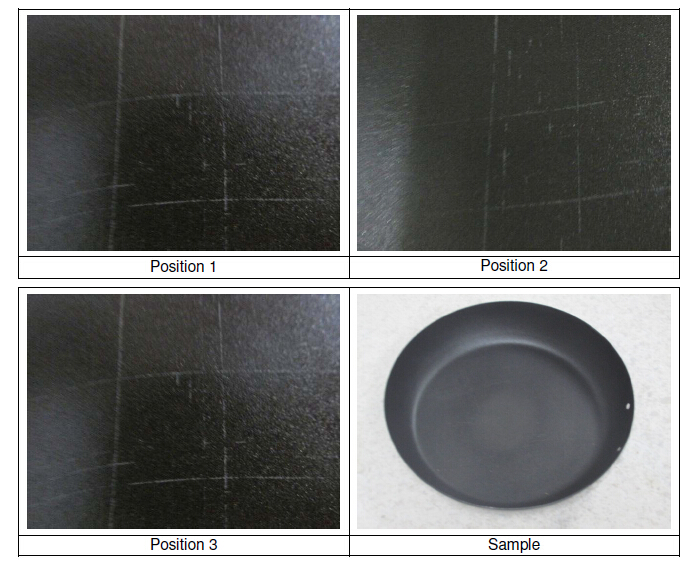

As you can see from the results above and the photos of the tested samples below, a Lotus Rock pan got a perfect score of 0; the edges of the cuts are completely smooth, and none of the squares of the lattice are detached. This excellent result is in part due to the fact that the coating on a Lotus Rock pan is not a standard PTFE based coating. All Lotus Rock pans have a very thick ceramic layer, up to 100 microns thick, on top of the heavy gauge carbon steel substrate. Nestled on top of the ceramic layer is a very thin silicon-oxide crystal coating which is so thin that it is very difficult for a utensil or other piece of equirement to dettach it from the ceramic layer below it. Therefore unlike a weakly bonded and thinly coated PTFE based coating, a Lotus Rock pan can, with its strongly constructed coating, be cooked on for an extended period of time without any fear that the coating will peel off or break up.

May 22, 2015 / arnoldtnn / 0 Comments

As has been noted previously on this blog, Lotus Rock cookware is a metal utensil safe product: stainless steel spatulas, knives and forks can be used on it without damaging the coating. In addition, a Lotus Rock pan can be scrubbed hard with a standard abrasive pad for cleaning without impairing the quality of the pan’s coating. The interior coating for all Lotus Rock pans has been tested and passed, by an independent testing authority, according to BS 7069 Abrasion and Scratch resistance testing standards.

However, although during cooking the interior coating of a pan does undoubtedly have to withstand a high degree of scratching from numerous kitchen utensils, what is not considered as much is the resistance to scratching of a pan’s exterior coating. When using some pots and pans for cooking, such as a stir wok or a crepe pan, it is often necessary to move them quite quickly to get ingredients around the pan or out onto some kind of serving dish. But if this is done over a cooking top surface such as a gas stove, with its sharp protruding edges, the exterior coating of a cookware utensil will, in all likelihood, need to withstand some heavy scratching. If the exterior coating is too soft or thin then these scratches will not only worsen the appearance of the pan quite considerably, but they might also expose the metal substrate beneath the coating to corrosion

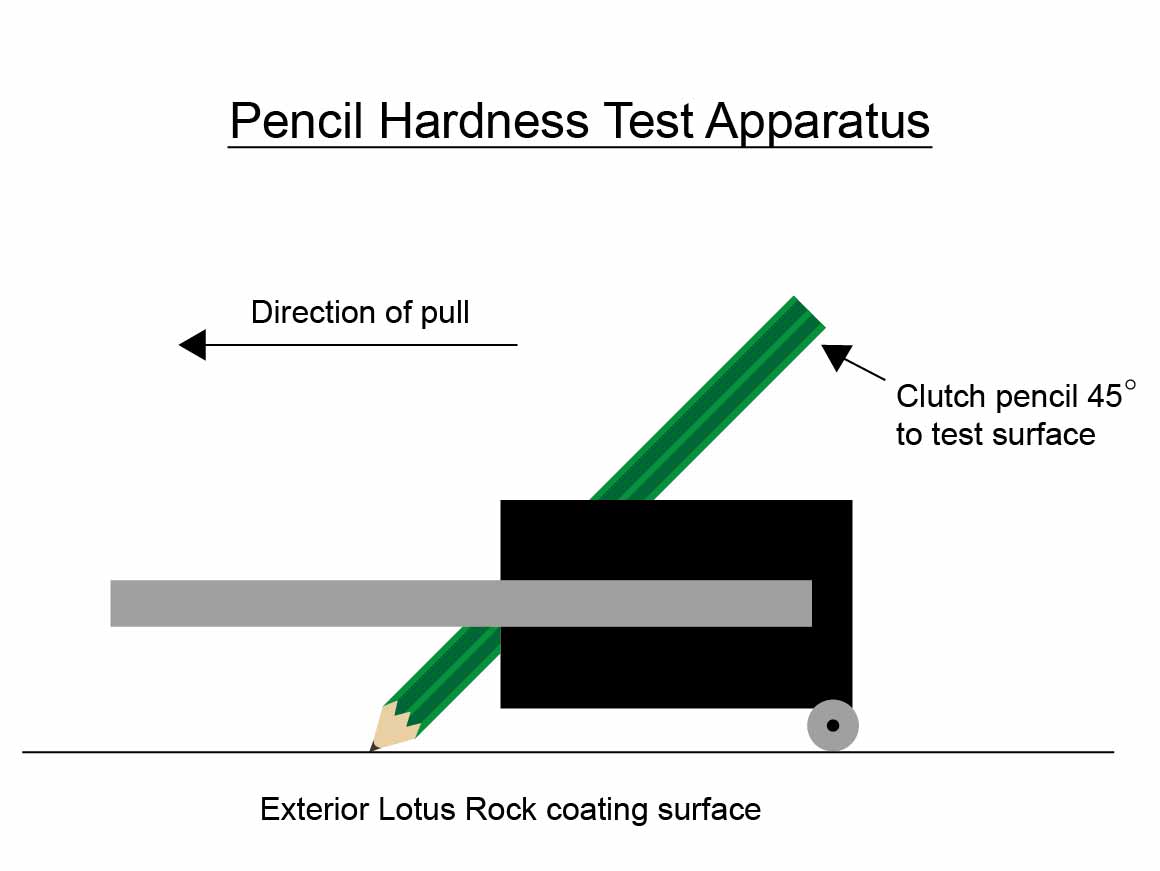

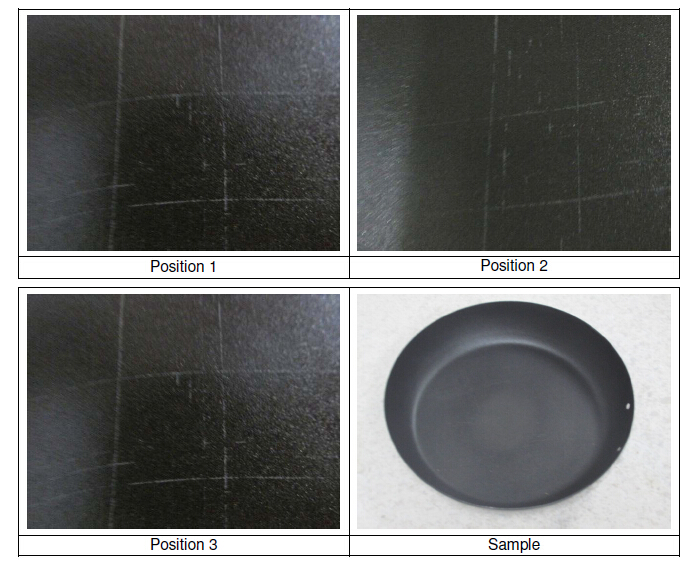

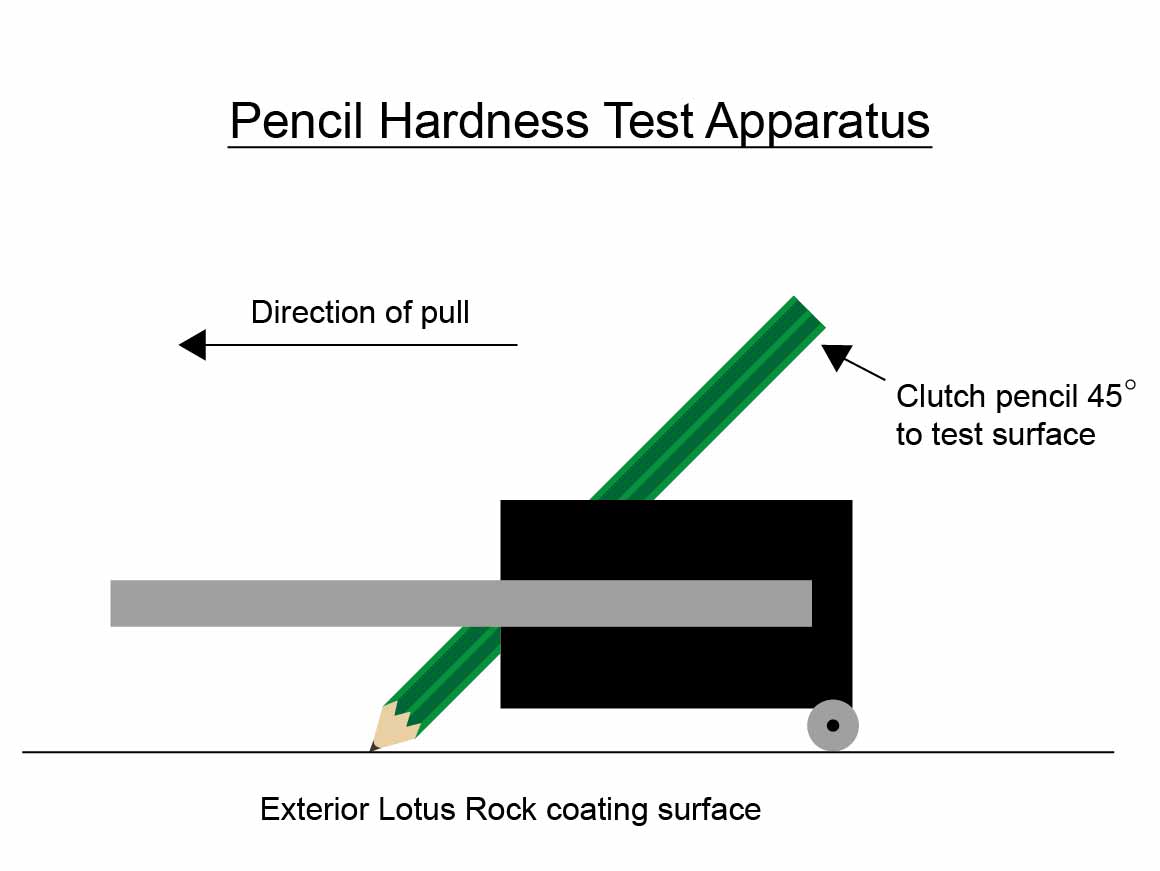

A Pencil Hardness test has been used by the kitchenware industry for many years to determine the scratch hardness for the exterior coating of a pan. This test uses special pencils with different degrees of hardness to scratch the coating, which then determines its hardness.

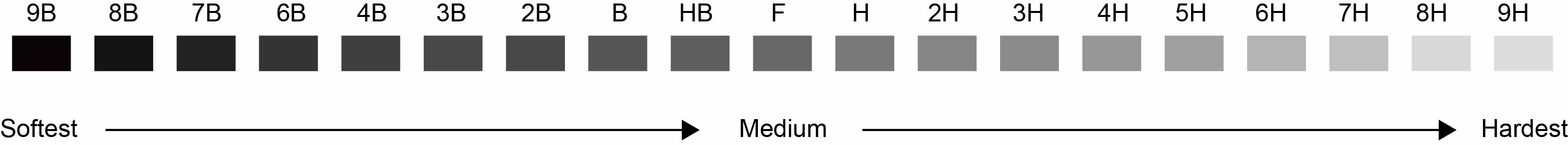

A complete set will have the following pencil gradings, starting with the hardest — 9H, 8H, 7H, 6H, 5H, 4H, 3H, 2H, F, HB, B, 2B, 3B, 4B, 5B, 6B, 7B, 8B and 9B (the latter is the softest pencil; it contains the most graphite and the least amount of clay). The “H” stands for “hardness” and the “B” stands for “blackness,” which comes from the amount of graphite used in the softer pencils.

The simplicity of the pencil hardness test is its great advantage. The special pencils used for doing the test are made of various combinations of graphite and clays, baked in ovens to harden their compositions. By adjusting the amounts of these two organic materials, the pencils are either very soft or quite hard.

BS EN 12983-1-2000+AC:2008 Pencil Hardness Test Procedure

The Pencil Hardness Test procedure, according to BS EN 12983-1-2000+AC:2008, is as follows:

Step 1 = Set up apparatus with a 5H lead loaded to either 4 N or 8 N + 0,2 N.

Step 2 = Draw the apparatus across 25mm of an untouched area of the test surface.

Step 3 = If the lead has cut a clean path through the coating, repeats steps 1 & 2 reducing the grade of the lead by one step each time until it fails to cut a clean path through to the substrate.

Step 4 = Report the hardness of the coating as the hardness of the first lead which failed to cut a clean path through to the substrate.

Evaluation

Generally, even with the stricter standard of a fixed pressure of 8.0 Newtons (765g±2%) applied to the exterior coating, a Lotus Rock pan can pass a Pencil Hardness test with a standard of at least 8H hardness. In fact, more often than not, even if a Lotus Rock pan’s outer coating is scratched a bit from the sharp edges of a gas stove, the surface can still be scrubbed with a standard abrasive pad and the scratch will in most cases be removed. This excellent scratch resistance allows a Lotus Rock pan to be used for a much longer period of time, than say a non-stick coated pan, most of which only have a thin, silicone polyester coating on the outside of the pan. For a standard pencil hardness test, without any heat applied to the surface, then a silicone polyester coating can pass at a 4H hardness standard. If, however, the ambient temperature test is included whereby the surface temperature of the pan is increased to 200 degrees, then a silicone polyester coating is liable to become quite soft, and will then only pass a 2H hardness standard. To counter this problem some manufacturers use a sol gel technology ceramic coating instead of a silicone polyester coating, which is usually twice as thick, with a stronger bonded construction. However, even this type of coating can only reach a 6H hardness standard, still below the Lotus Rock scratch resistant quality of 8H.

May 15, 2015 / arnoldtnn / 0 Comments

The term ‘heavy metals’, is most commonly used to describe metallic elements of higher atomic mass that are toxic at low concentrations. If a consumer product, which is used for contact with food, has high levels of a heavy metal then it can be hazardous to human health. The short term effects of heavy metal poisoning can range from skin irritation to vomiting, but high level exposure can cause anything from liver damage to renal failure.

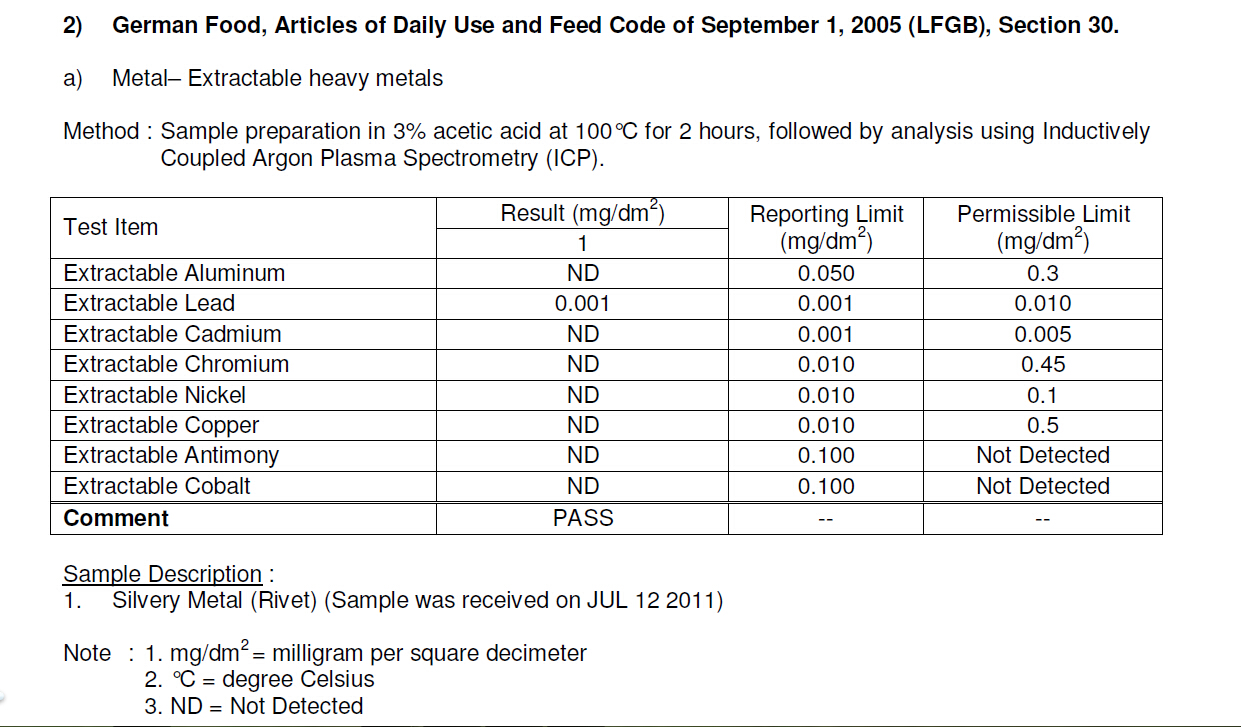

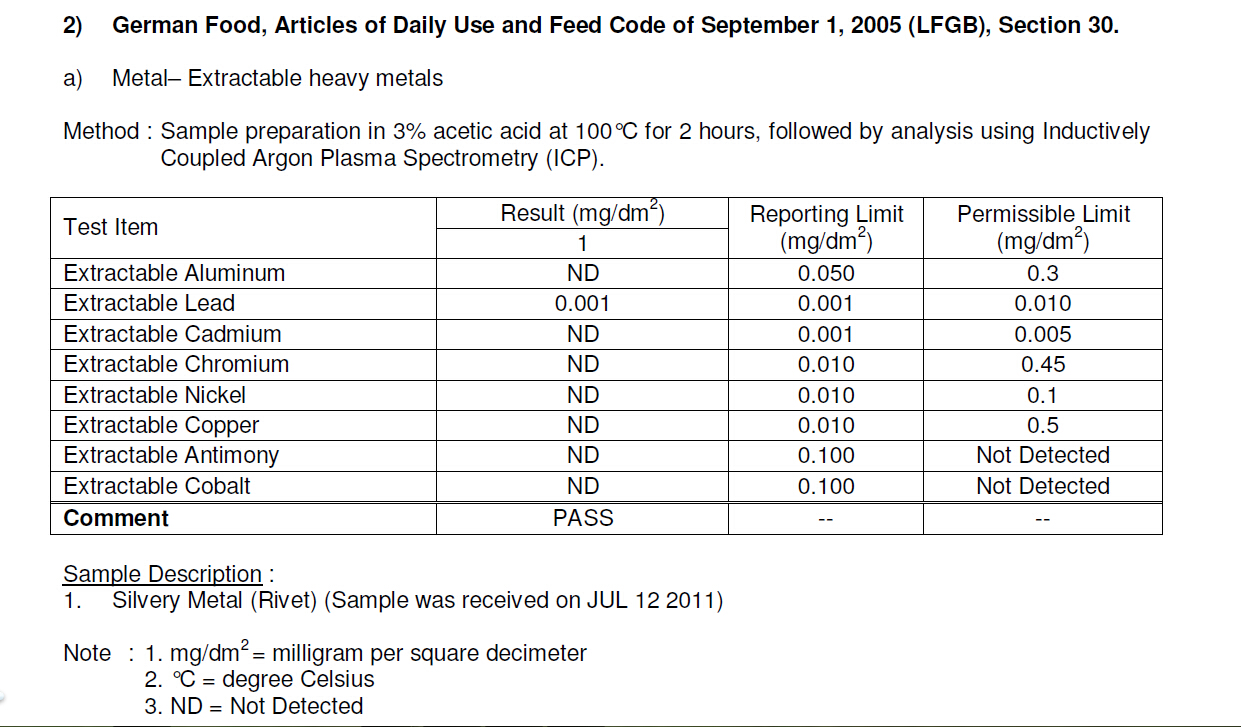

In order to demonstrate that all Lotus Rock pans are free of heavy metals that can leach into cooked food and cause poisoning, an Extractable Heavy Metals Test was commissioned with SGS Testing Services Ltd. The testing standards were done in accordance with LFGB* (German food law) regulations.

*In September 2005, the new German Food commodity and Feed Law (Lebensmittel – Bedarfsgegenstandegesetz und Futtermittelegsetzbuch –LFGB) replaced the old German Food & Commodities Act (Lebensmittel und Bedarfsgegenstandegesetz–LMBG). Within the kitchenware industry LFGB is considered to have the most stringent test standards for assessing the level at which heavy metals can be extracted from a manufactured product.

LFGB Extractable Heavy Metals Test Result

As is shown above, a number of heavy metals were tested for in the Lotus Rock pan using an acid solution, for example, similar to a recipe which might use tomatoes to make a sauce. Some of the heavy metals that were tested for included Cadmium and Mercury; these are toxic to the human body as they undergo bioaccumulation. This means that they are absorbed by the body at a faster rate than they can be removed, and, over a period of time, can cause chronic poisoning, even if the levels found in the environment are low. Other heavy metals, such as Copper, are essential to bodily functions, but at higher levels they begin to alter metabolic processes and become toxic. Other than Cadmium, the other heavy metal considered to be most toxic to human health is Lead. High levels of exposure to lead can have numerous, severe health problems. These include neurological damage and damage to organs such as the liver and kidney.