January 14, 2026 / arnoldtnn / 0 Comments

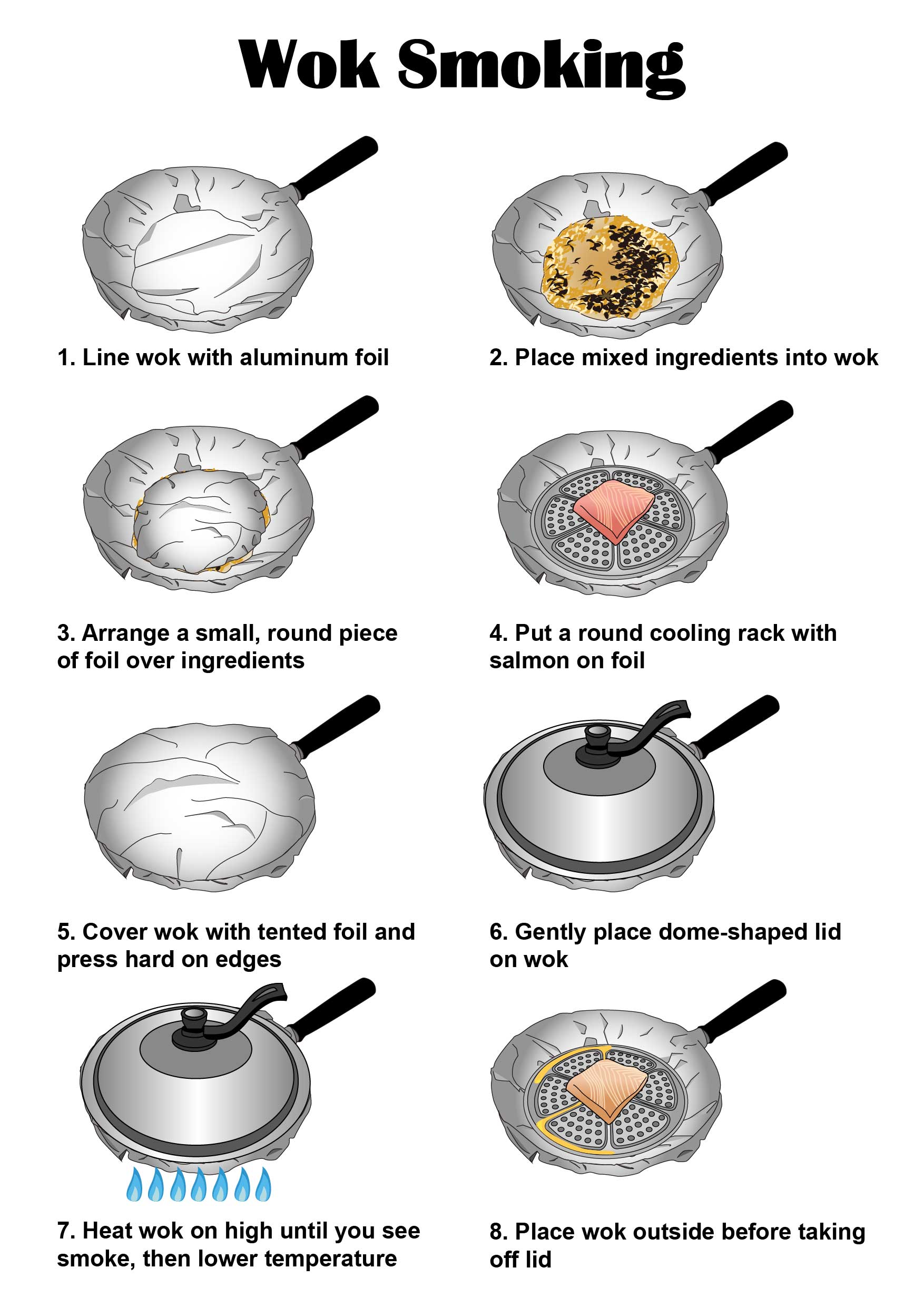

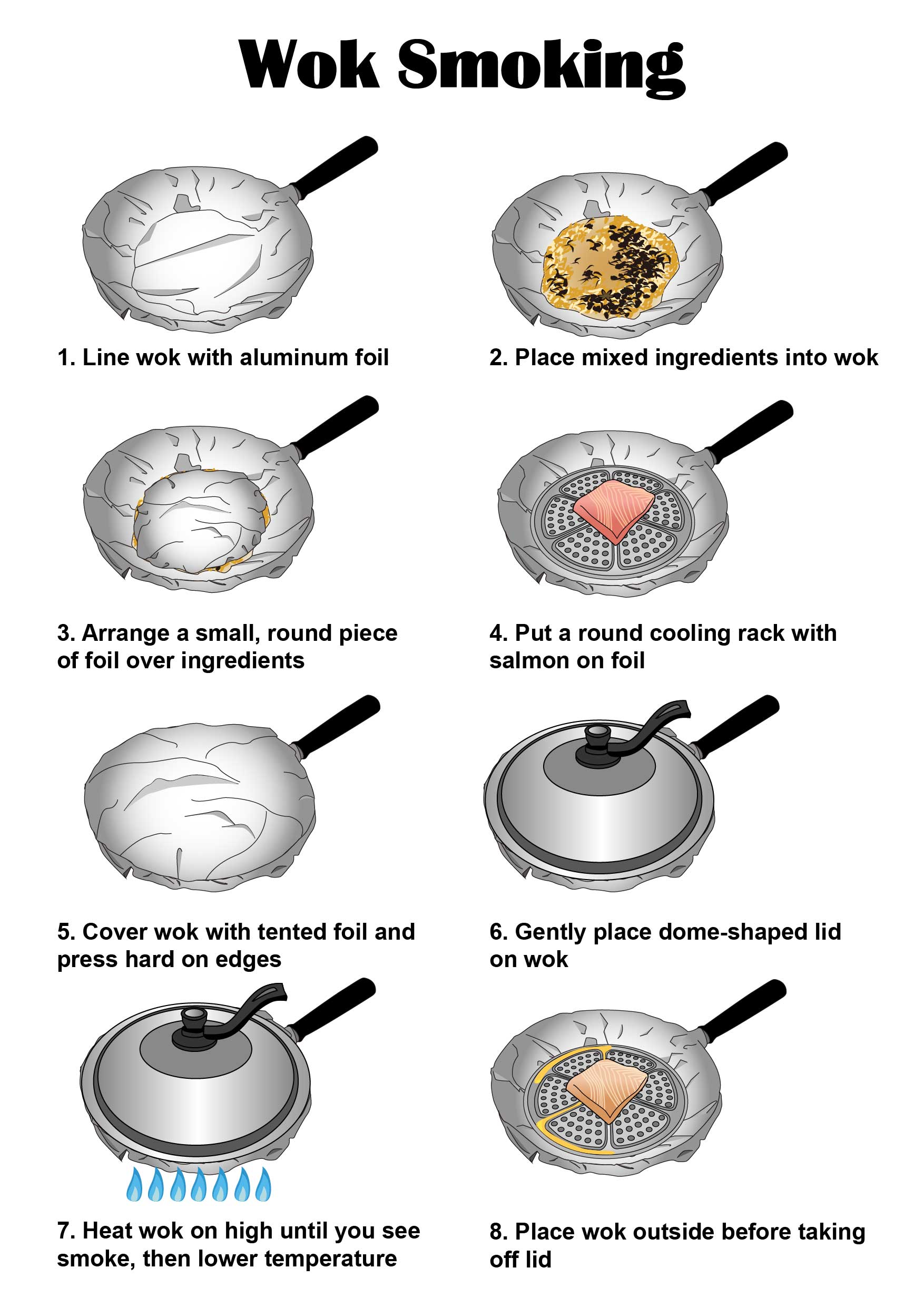

Lotus Rock’s high heat resistant coating and strongly constructed base make it ideal for smoking various types of popular dishes, such as salmon and chicken wings. Unlike with an outdoor grill or smoker, the heat under a Lotus Rock wok is much more adjustable than the blast you get from hot coals, which expands the possibilities when it comes to choosing ingredients to smoke with. All you need to smoke with a Lotus Rock wok are the correct ingredients, a rack and some tented aluminum foil.

January 14, 2026 / arnoldtnn / 0 Comments

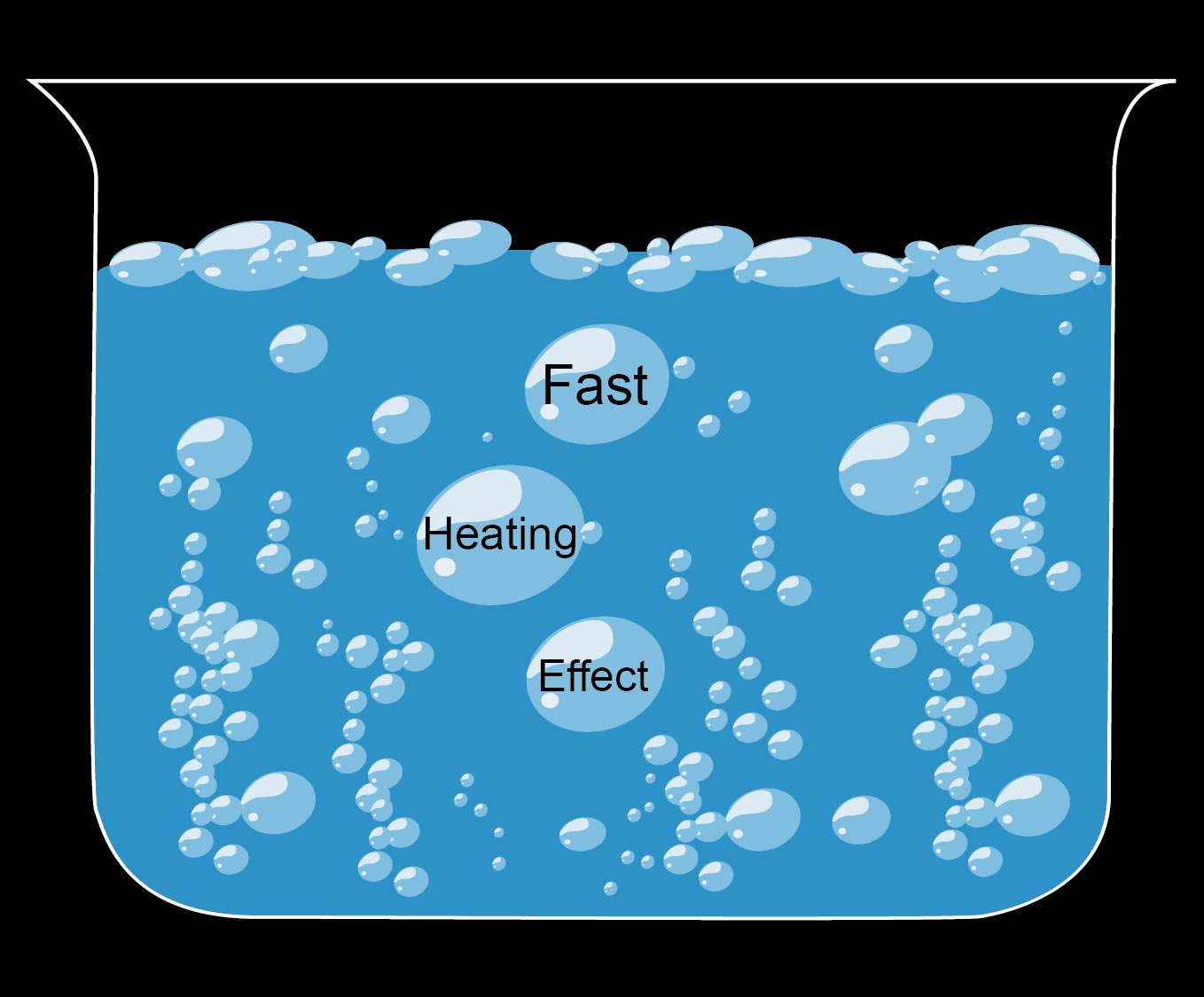

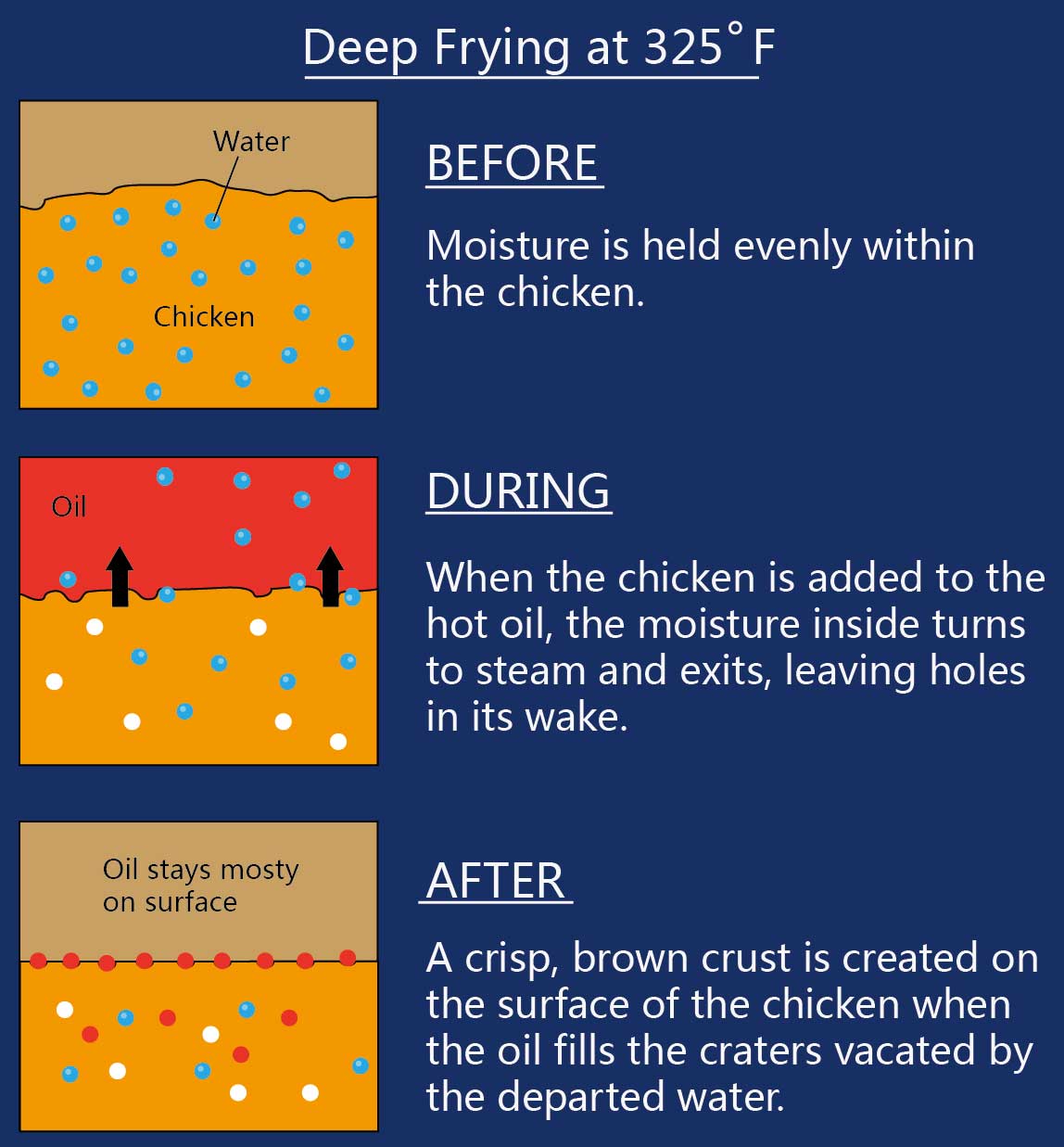

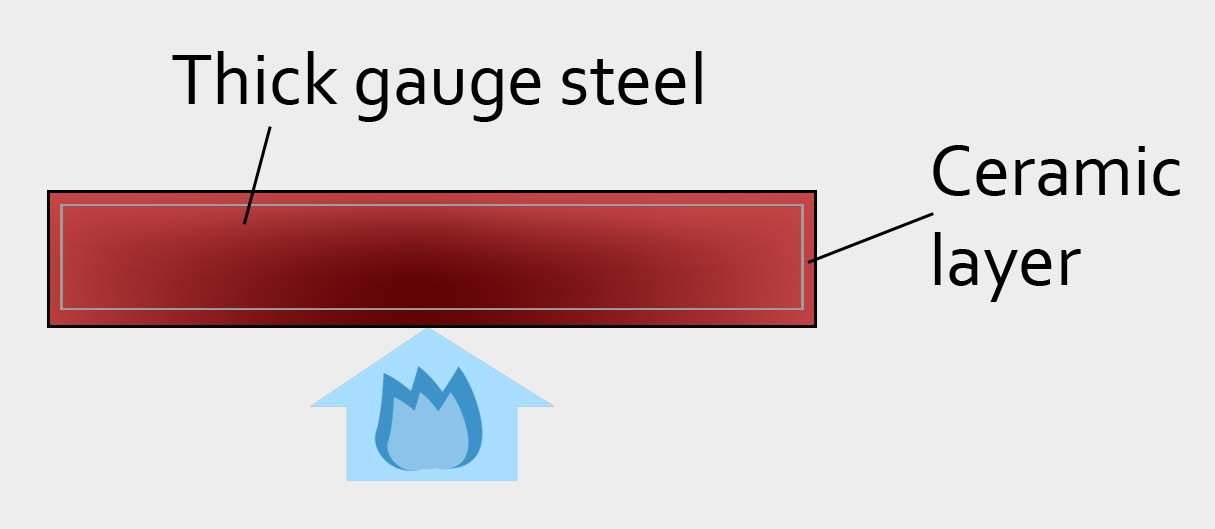

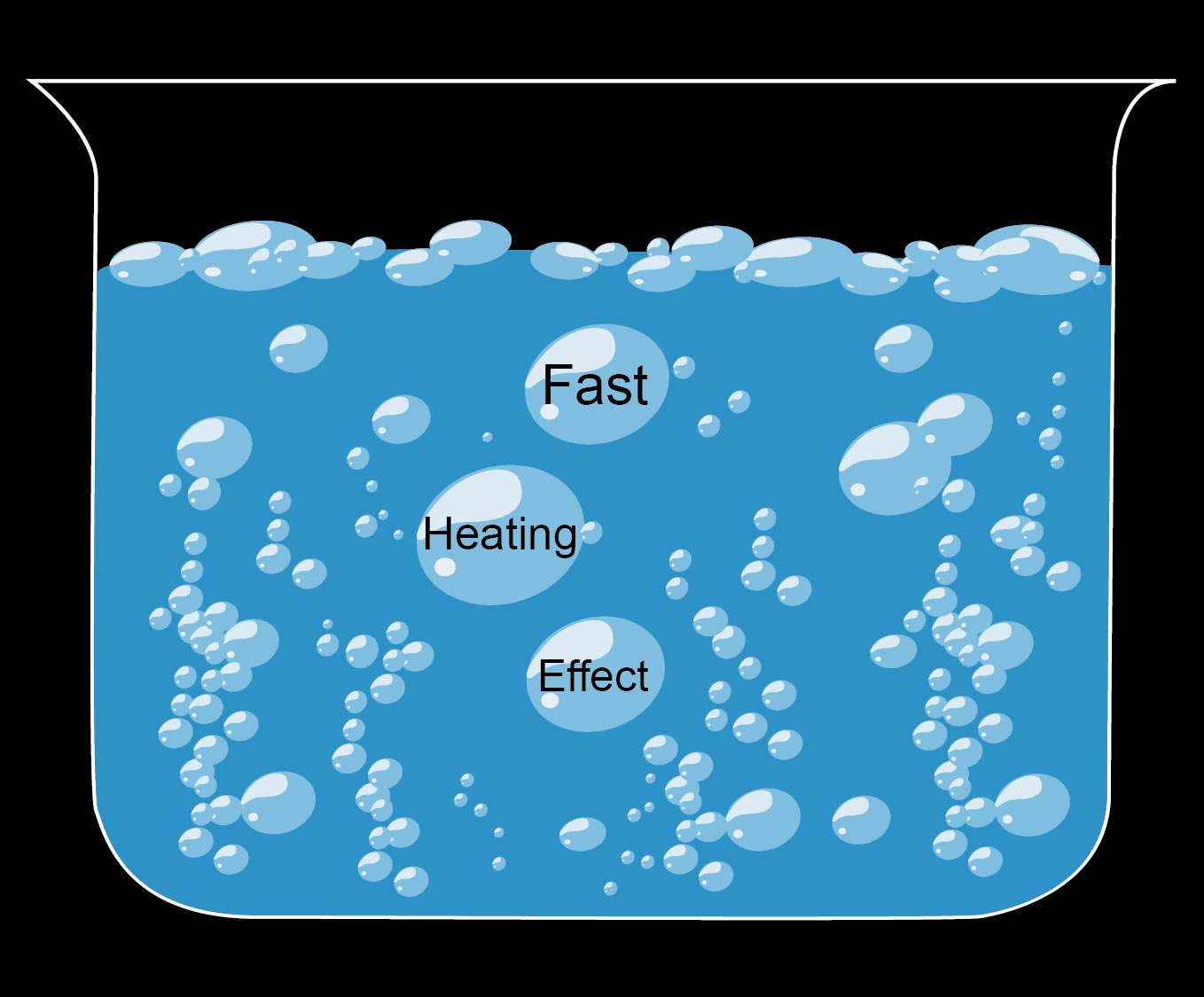

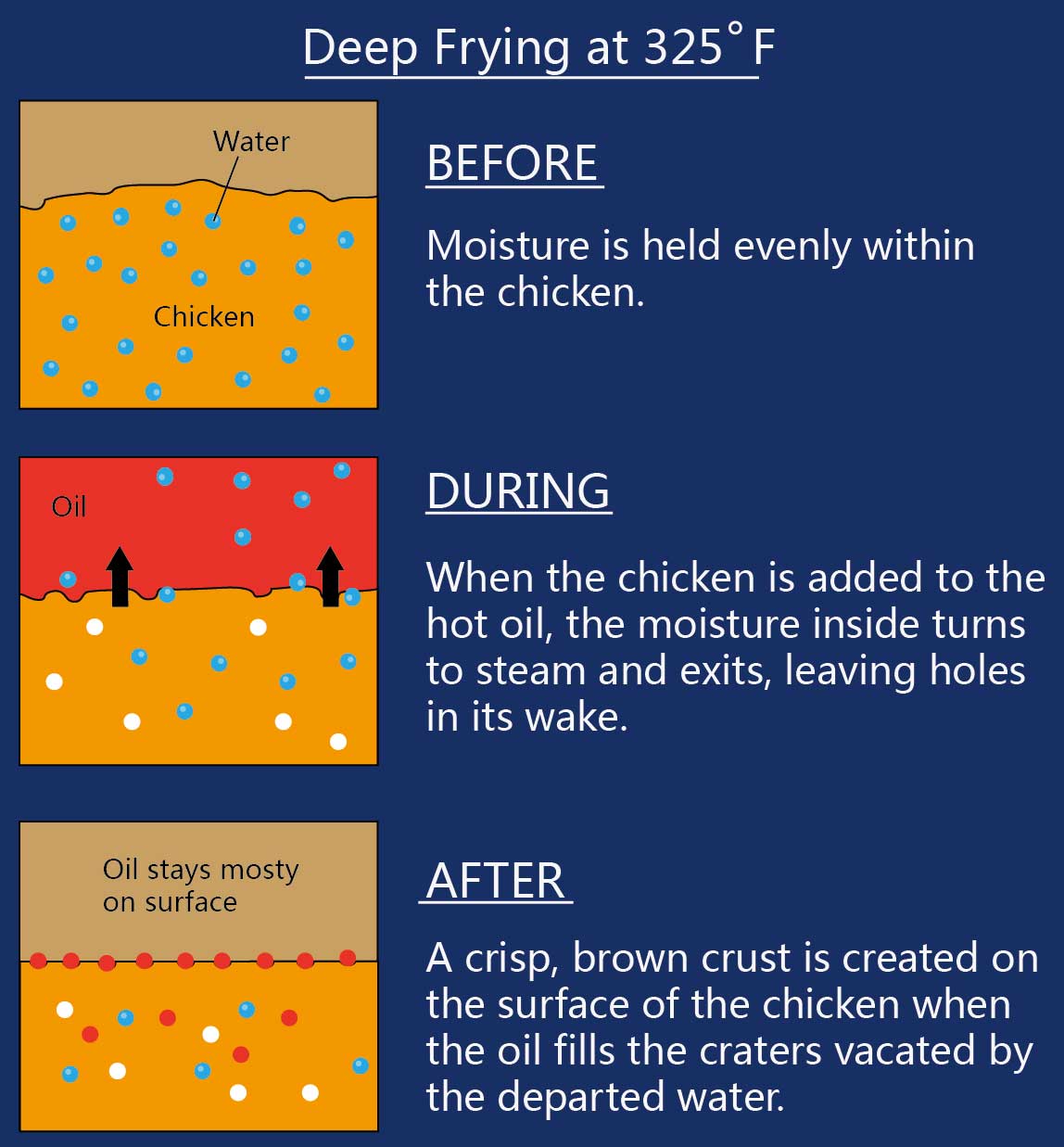

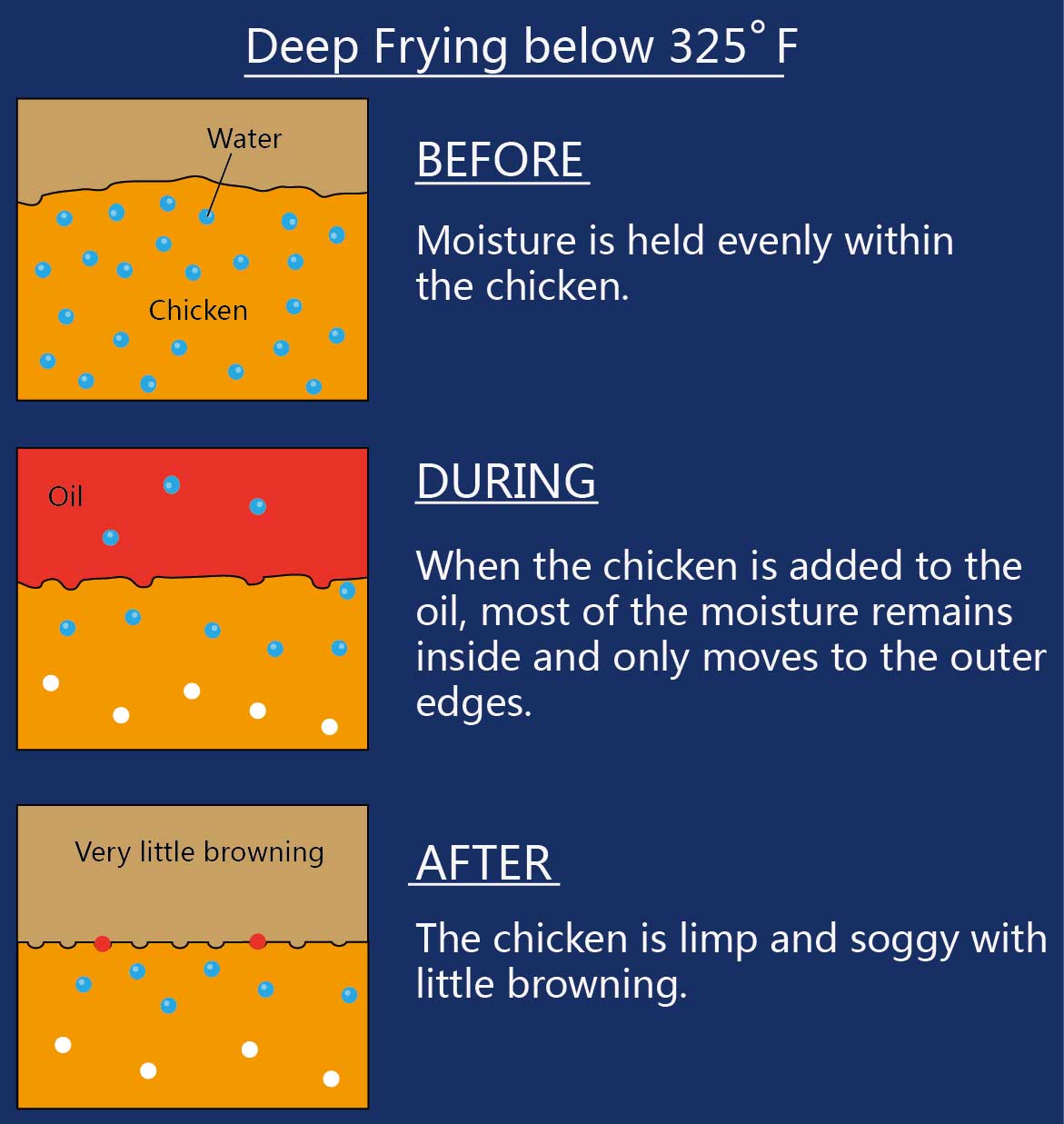

Getting the right oil temperature inside the wok is very important for good deep fat frying because if it is not hot enough, then the moisture inside the food will not dry out, and the trademark brown and crispy crust will not form. A Lotus Rock stir wok’s material cpmposition and shape make it particularly suitable for deep frying. Fast heating effect can get the oil up to a high temperature quickly. The heavy gauge and density of the steel can maintain a high temperature even when food is being added.

January 14, 2026 / arnoldtnn / 0 Comments

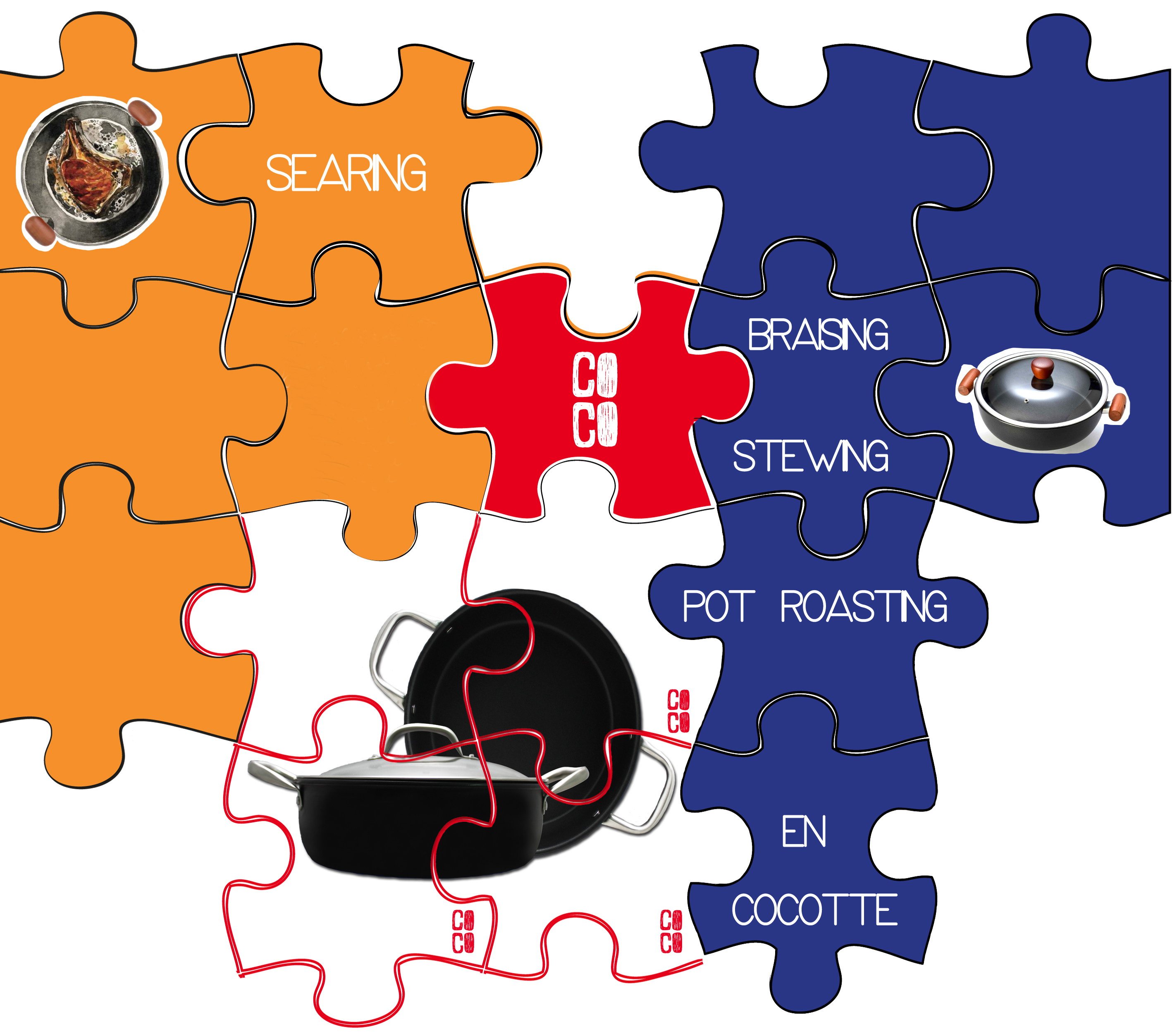

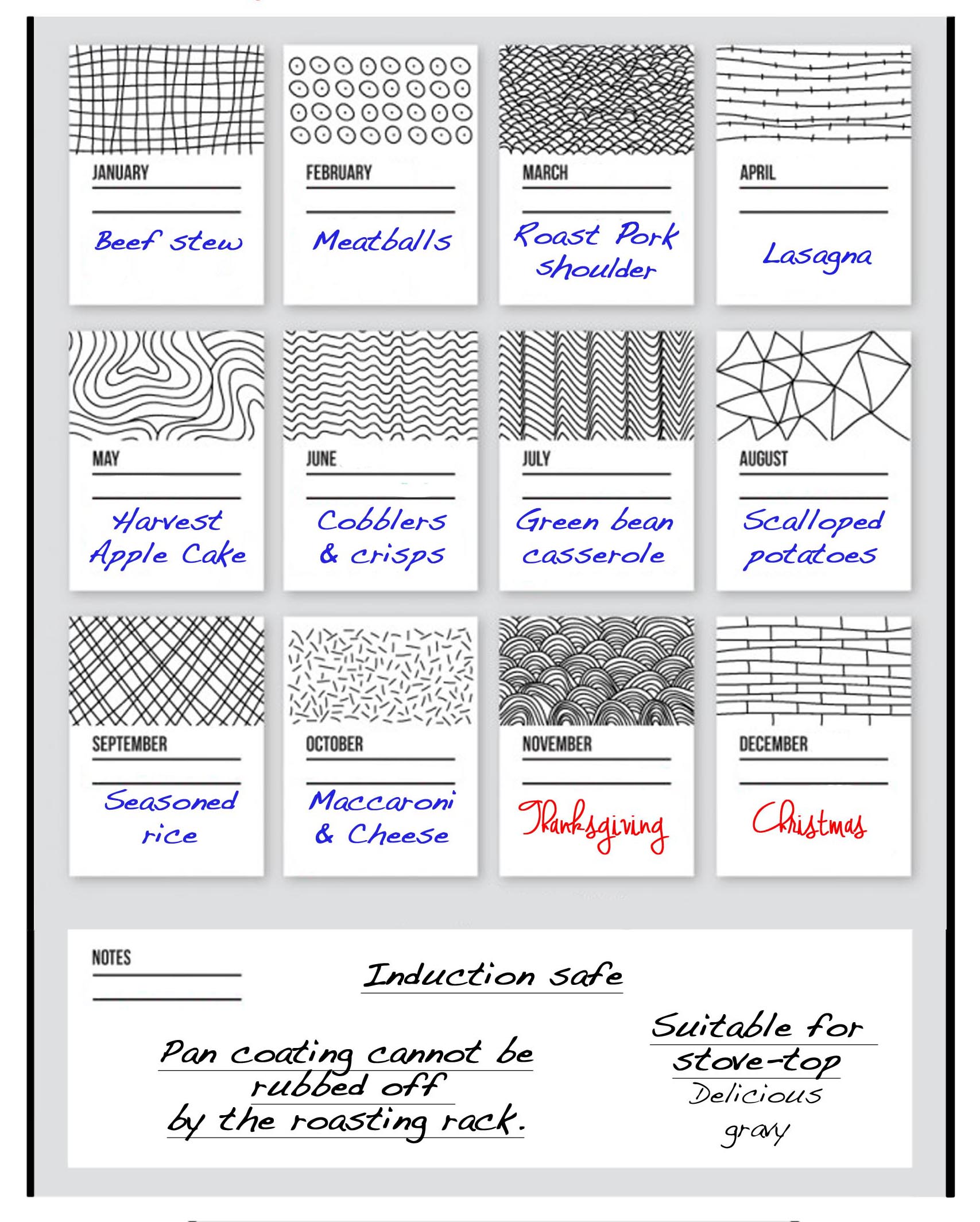

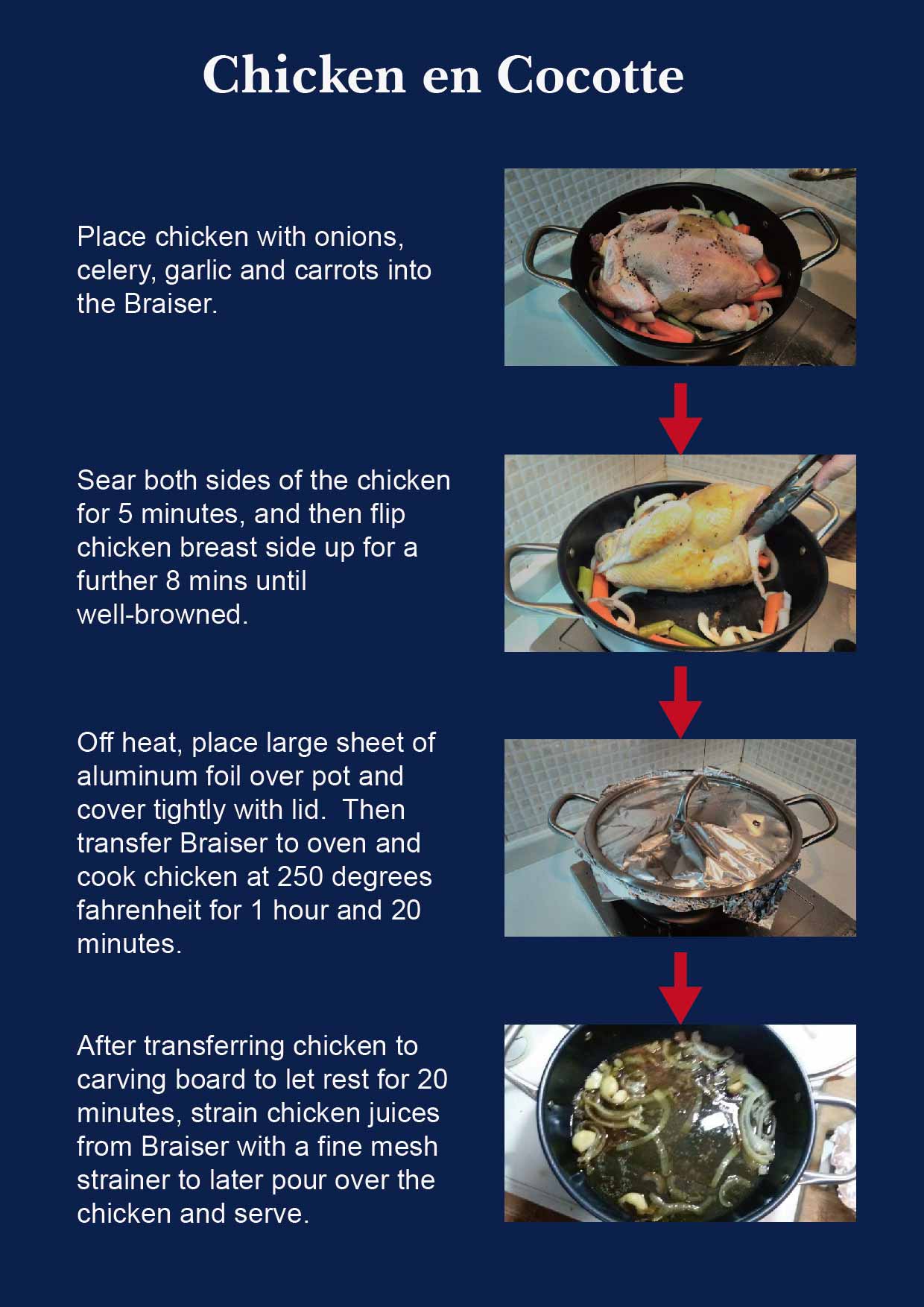

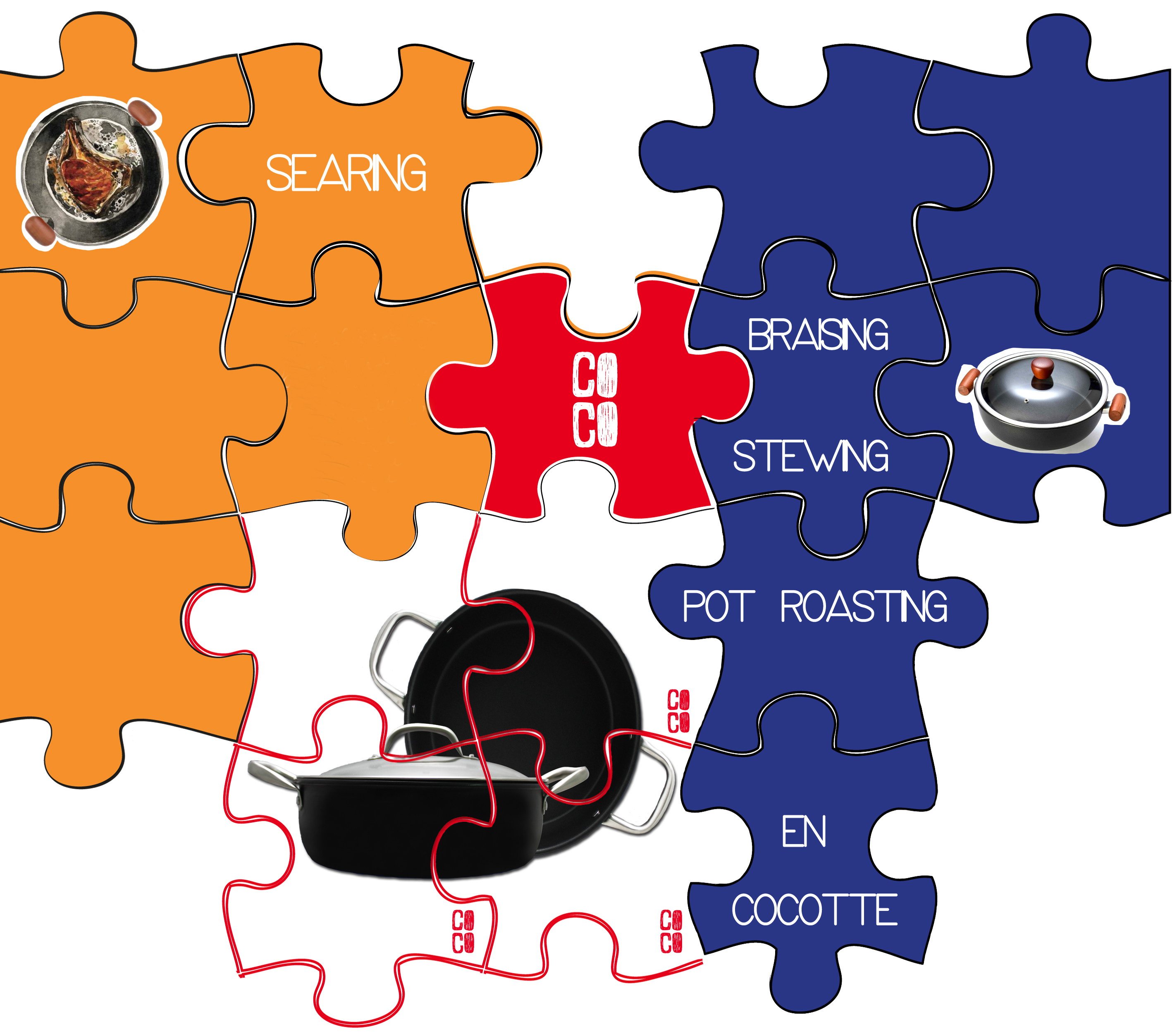

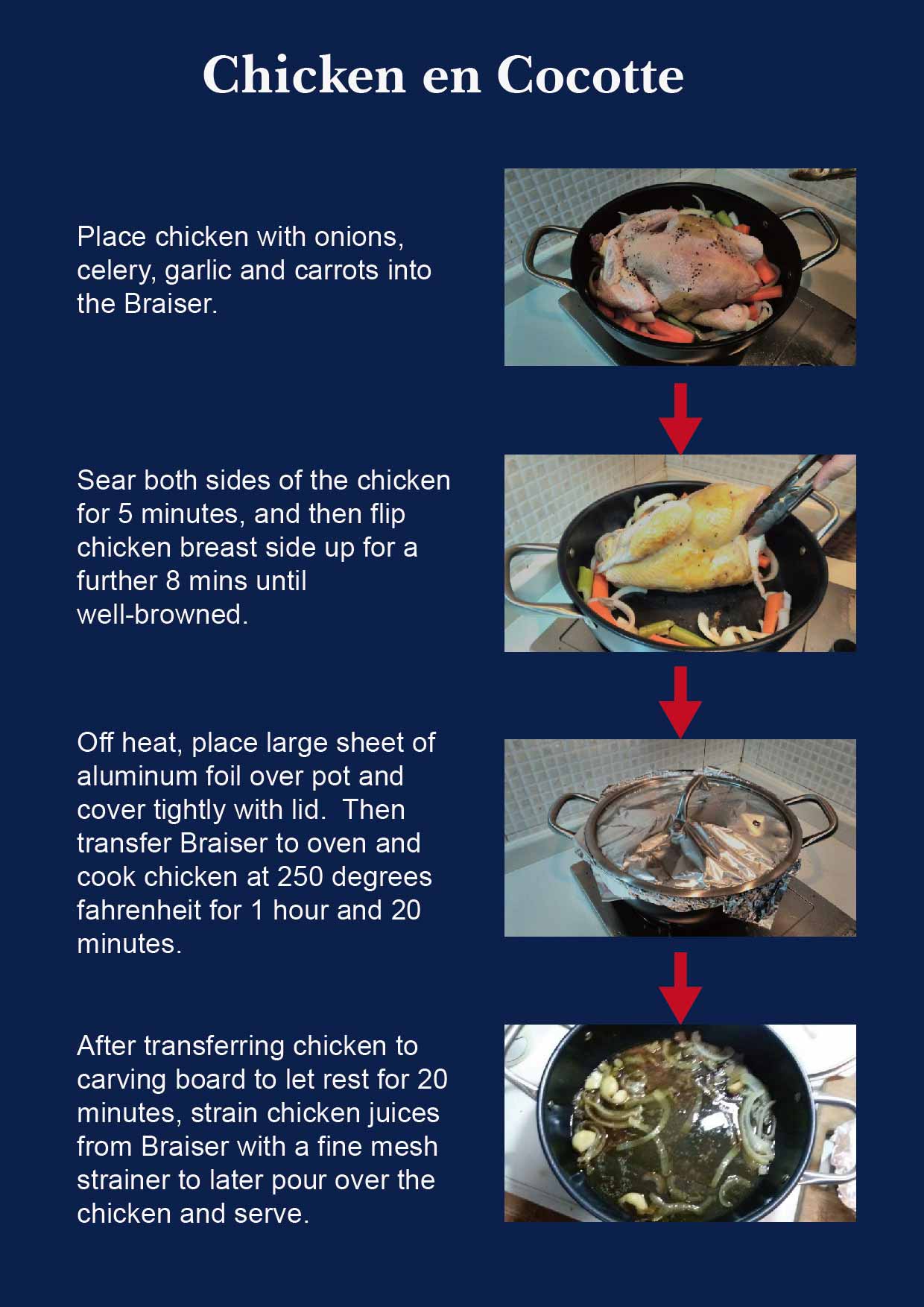

Combination Cooking involves both dry and moist-heat cooking. This type of cooking method requires long, gentle cooking to turn tougher cuts of meat into those fork-tender dishes that we often refer to as “comfort foods”.

A Lotus Rock Braiser is best used for recipes which require meats or vegetables that need to be seared quickly in the open pan and then covered with a lid to cook slowly in their liquid (either in the oven or over the stove). Popular combination cooking techniques used with this pan after searing include braiser, stewing, pot roasting and en cocotte.

January 14, 2026 / arnoldtnn / 0 Comments

Green vegetables, such as Broccoli, Asparagus, and Green Beans, contain the pigment Chlorophyll, which is very sensitive to heat. lf these vegetables are cooked for too long they will suffer major colour loss. The fast heating ating effect of a Lotus Rock Sauce pan or Casserole is the perfect utensil to preserve the pigment of green vegetables. A quick boiling in water not only maintains the flavour and colour of the vegetables, but also produces the desired texture too.

September 16, 2025 / arnoldtnn / 0 Comments

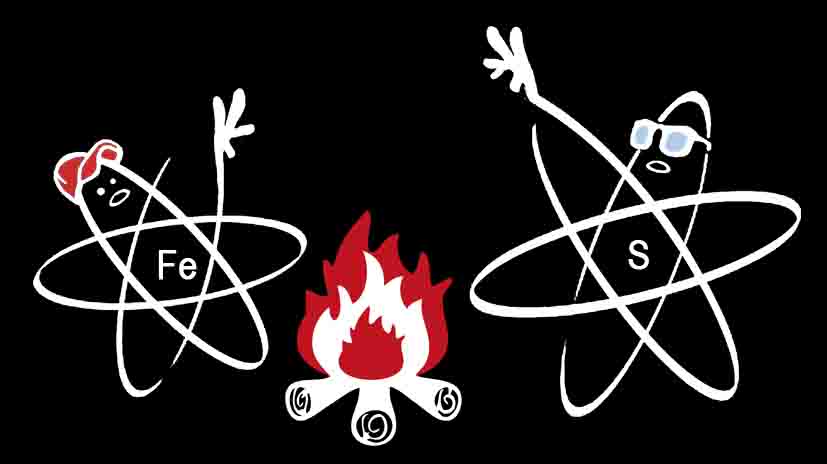

Making dinner with an electromagnet may seem improbable to cooks who have grown up with traditional natural gas and electric cooktops, but in recent year’s induction cooking tops have become increasingly popular. Initially they were mainly used in Asia and Europe, but now they have become more widespread in North American kitchens as well.

Advantages of Induction cooking top surfaces include:

- Safe. When the coil is turned on it generates a magnetic field that will only heat up the cookware. It doesn’t heat up the cooking surface. So unlike electric or halogen cooking tops there is no danger of accidentally burning yourself by touching the surface.

- Efficient and fast. Induction cooking tops bring water to boil faster than gas or electric cooktops, and it’s incredibly energy efficient. In fact, 90% of the energy used is transferred directly to the pan for cooking, versus only about 40% for gas stoves.

- Easier to clean. As mentioned above, because an induction cooking top surface is not magnetic, it stays cool throughout the cooking process – this means that accidental spills aren’t burned on and hard to clean.

One of the many significant benefits of Lotus Rock cookware is that it is induction safe; unlike aluminum or copper pans, which are not permitted for use on on this type of cooking top surface. Aluminum or copper pans can be used on induction if they have a special plated bottom attached to them, but because Lotus Rock pans are produced with a thick 2.0mm carbon steel gauge they are already induction safe and this type of plated bottom is not needed.

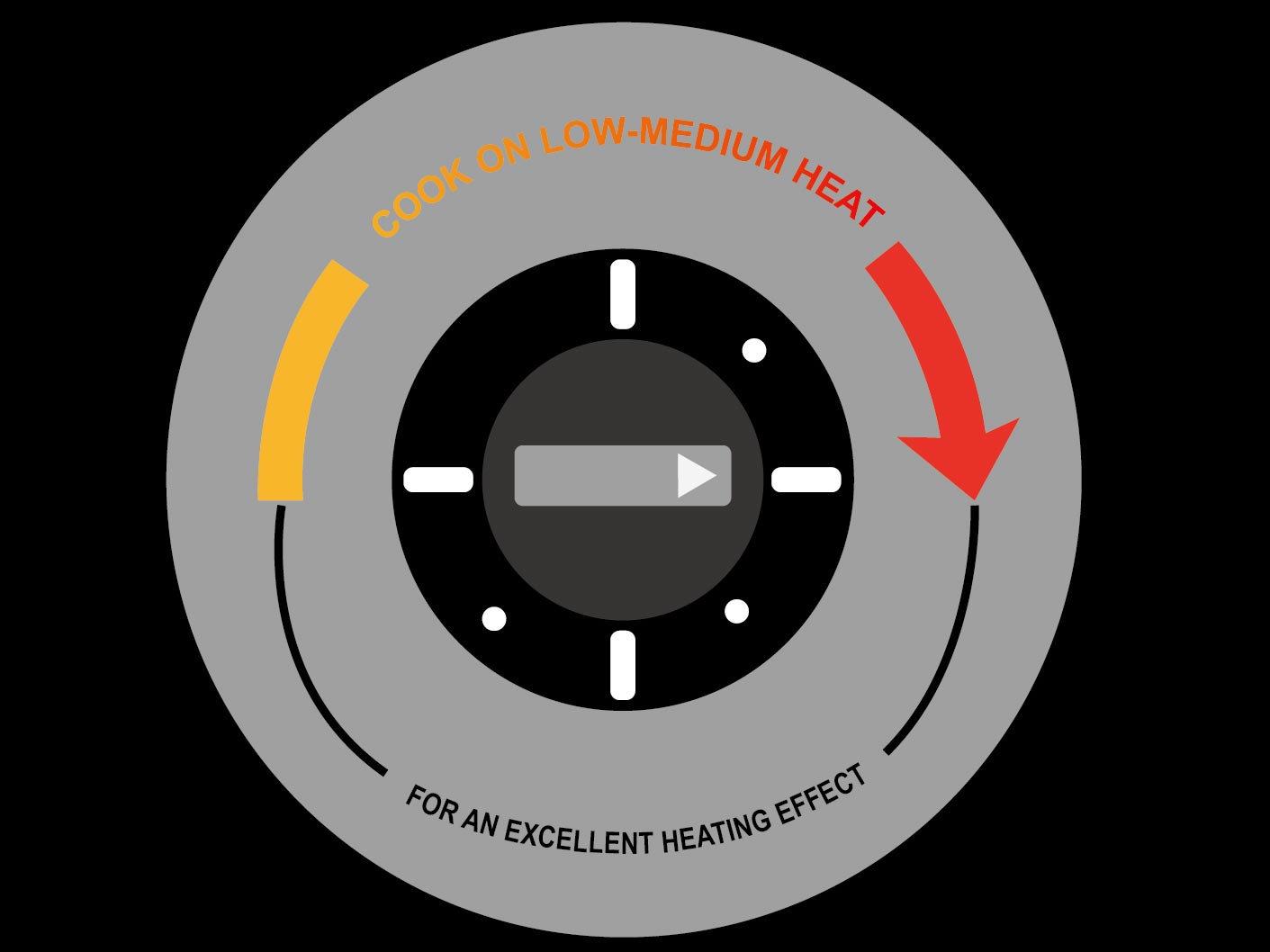

The fact that Lotus Rock cookware doesn’t need a plated bottom also has some other advantages. First, by having no steel plate at the bottom of the pan the appearance of Lotus Rock cookware is not impaired; all pans have the same tough, glossy black look on both their interior and exterior. Second, although some aluminum and copper pans may have a plated bottom to make them induction safe, if these are not applied properly then either the pan will make a bothersome noise or they will not conduct heat effectively to the pan’s surface. Lotus Rock’s heavy gauge carbon steel substrate along with its thick ceramic interior and exterior means that on an induction cooking heat is spread evenly and quickly around the surface of the pan for an excellent heating effect.

Lotus Rock pans can be improved for use on induction cooking tops with the addition of the Stable Concave design.

September 14, 2025 / arnoldtnn / 3 Comments

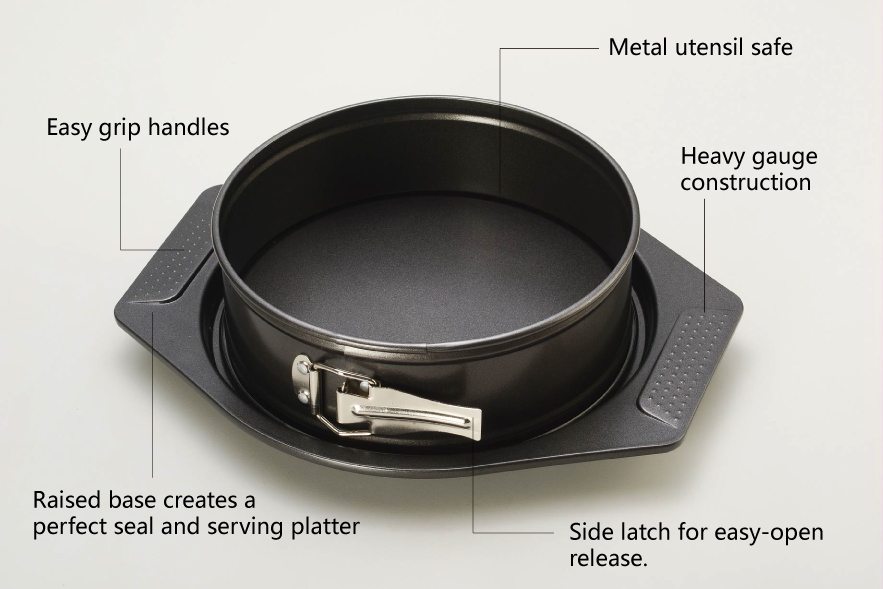

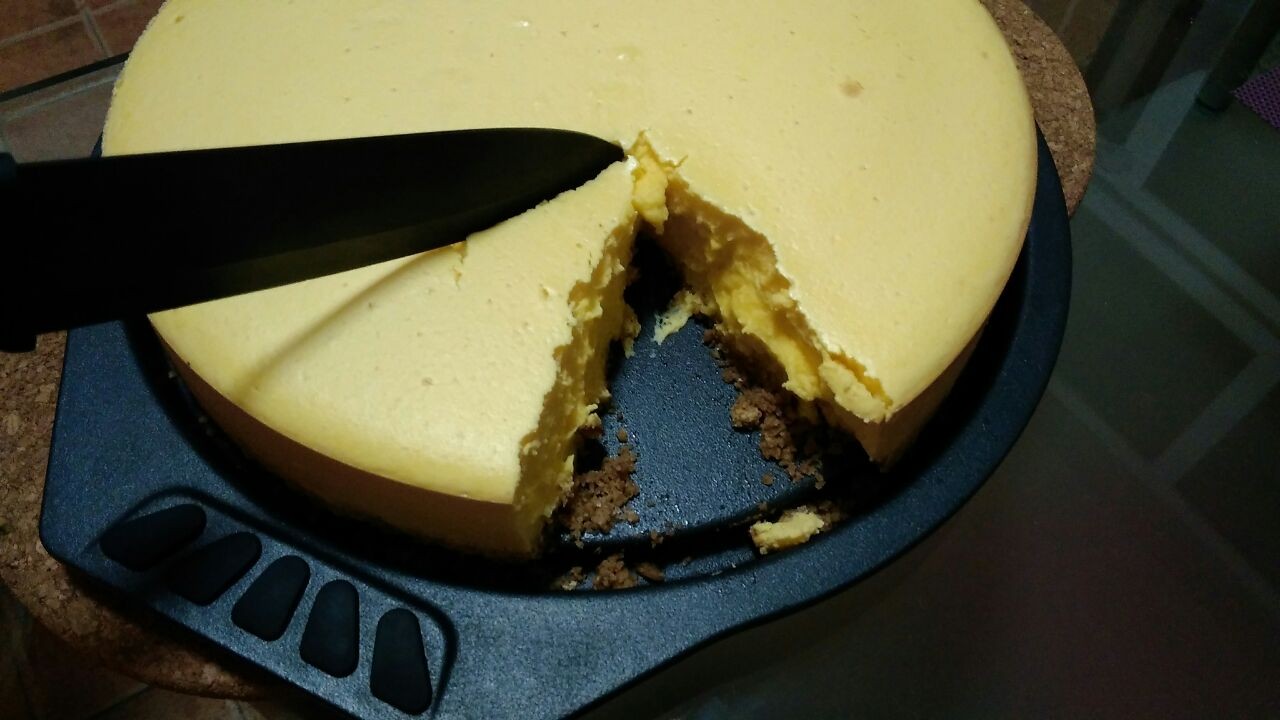

Well-designed paella pans encourage the formation of a light crust of rice on the bottom of the pan. In Spanish this is known as Socarrat which means lightly toasted. This is the most prized part of a Spanish paella and can only be achieved with a paella pan. The secret is to increase the heat during the last 3 minutes or so of cooking. If you listen carefully the rice will begin to crackle slightly. Take the paella off the heat when this happens in case it begins to burn. The objective is to get toasted rice on the base (which has a nutty aroma) rather than burnt rice.

Well-designed paella pans encourage the formation of a light crust of rice on the bottom of the pan. In Spanish this is known as Socarrat which means lightly toasted. This is the most prized part of a Spanish paella and can only be achieved with a paella pan. The secret is to increase the heat during the last 3 minutes or so of cooking. If you listen carefully the rice will begin to crackle slightly. Take the paella off the heat when this happens in case it begins to burn. The objective is to get toasted rice on the base (which has a nutty aroma) rather than burnt rice.

A Lotus Rock paella pan is perfect for achieving Socarrat. This is because without oiling the surface of it rice can stick to the pan and then the delicious, caramelized crust can be formed. Non-stick pans on the other hand are not ideal because they don’t allow rice to stick to the bottom and for Socarrat to form.

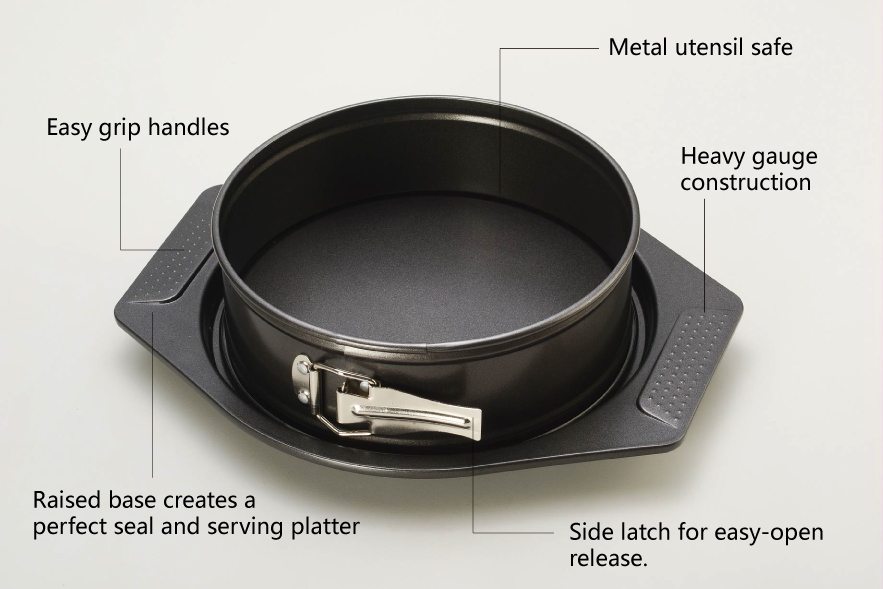

The standard way to check if Socarrat has been formed or not is to insert a fork into the rice, if a slight resistance is felt just before the fork reaches the base of the pan then a layer of Socarrat exists. General non-stick pans might be easily damaged while checking for Socarrat as the sharp edges of a metal fork penetrates the bottom layer of the rice and scratches the coating. However, with a Lotus Rock paella pan this test can be done without fear because the highly durable, thick ceramic coating is metal utensil safe, with excellent scratch resistance.

The standard way to check if Socarrat has been formed or not is to insert a fork into the rice, if a slight resistance is felt just before the fork reaches the base of the pan then a layer of Socarrat exists. General non-stick pans might be easily damaged while checking for Socarrat as the sharp edges of a metal fork penetrates the bottom layer of the rice and scratches the coating. However, with a Lotus Rock paella pan this test can be done without fear because the highly durable, thick ceramic coating is metal utensil safe, with excellent scratch resistance.

A significant benefit of using dual sided steel handles with the Lotus Rock paella pan is is to increase its versatility: for use not only on the stove, but also for over the grill and in the oven, with an oven-safe temperature to 650 F. Restaurant chefs quick sear ingredients with carbon steel pans to develop a brown crust, and then slide them into the oven to cook through the interior for a moist, juicy finish. With a Lotus Rock paella pan, so can you!

Product Features

- Heavy weight 2.0mm steel gauge transfers and retains heat evenly.

- Thick enamel coating is metal utensil safe.

- Resistant to rust, chipping and cracking, the lipophilic coating only needs cooking oil for non-stick release when the recipe requires it.

- Specially formulated black matte interior has high heat resistance (650 degrees Fahrenheit) and a rougher surface for better browning.

- Smooth base compatible with all cooktops, including induction.

- Double-riveted stainless-steel handles for comfortable grip and long-life durability.

- Ideal shape and size to use as a paella pan, skillet, saute pan and grill pan.

September 9, 2025 / arnoldtnn / 0 Comments

The very best stir-fries will have a hint of what is called Wok Hei, or the “breath of the wok“. This is a complex smoky flavour that is only achieved by cooking fresh ingredients over extreme heat, meaning that the flavour develops while simultaneously retaining the textural crunch. Lotus Rock’s construction and coating configuration is ideally suited for a stir wok to impart the types of flavours and tastes associated with Wok Hei.

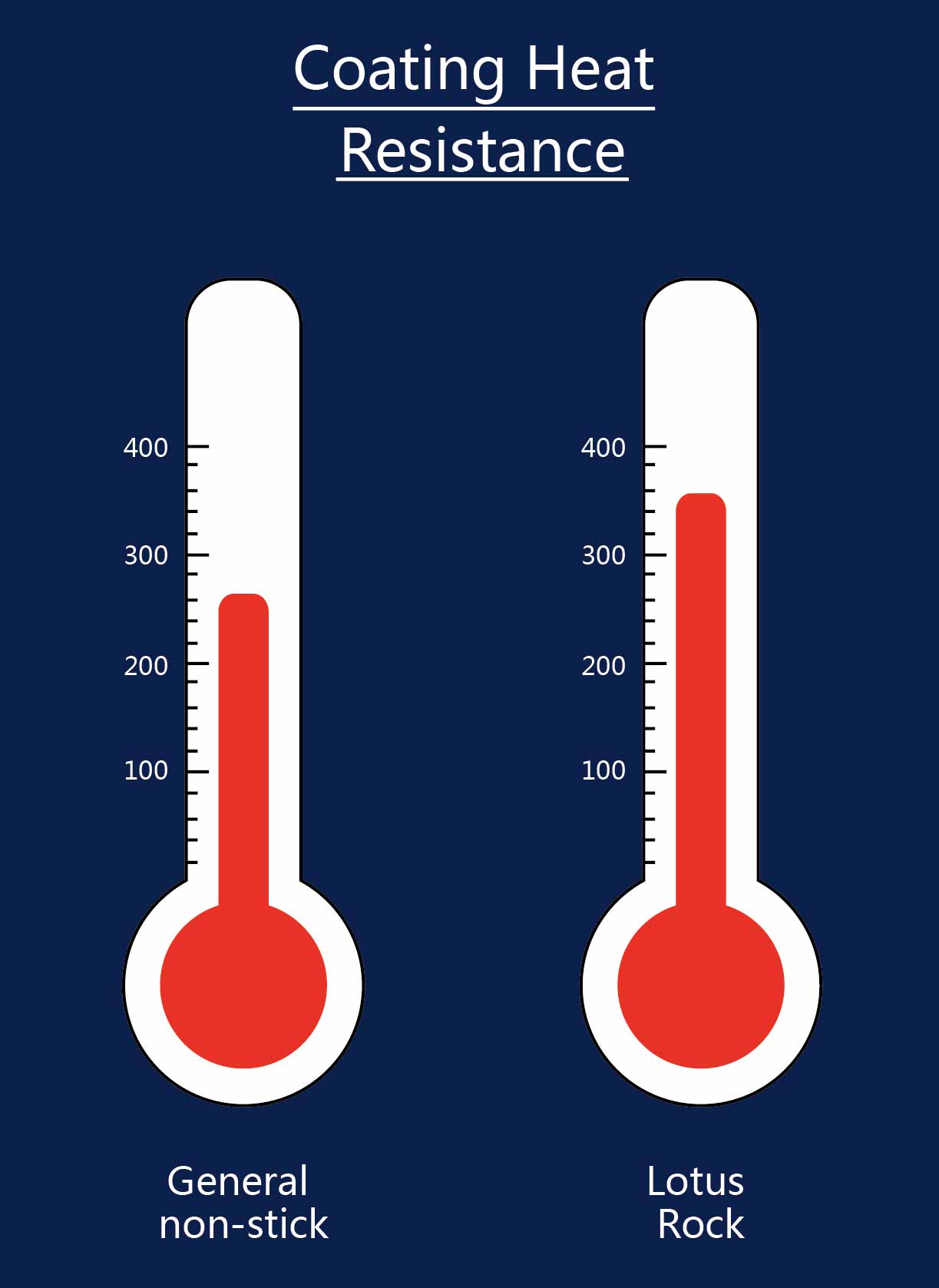

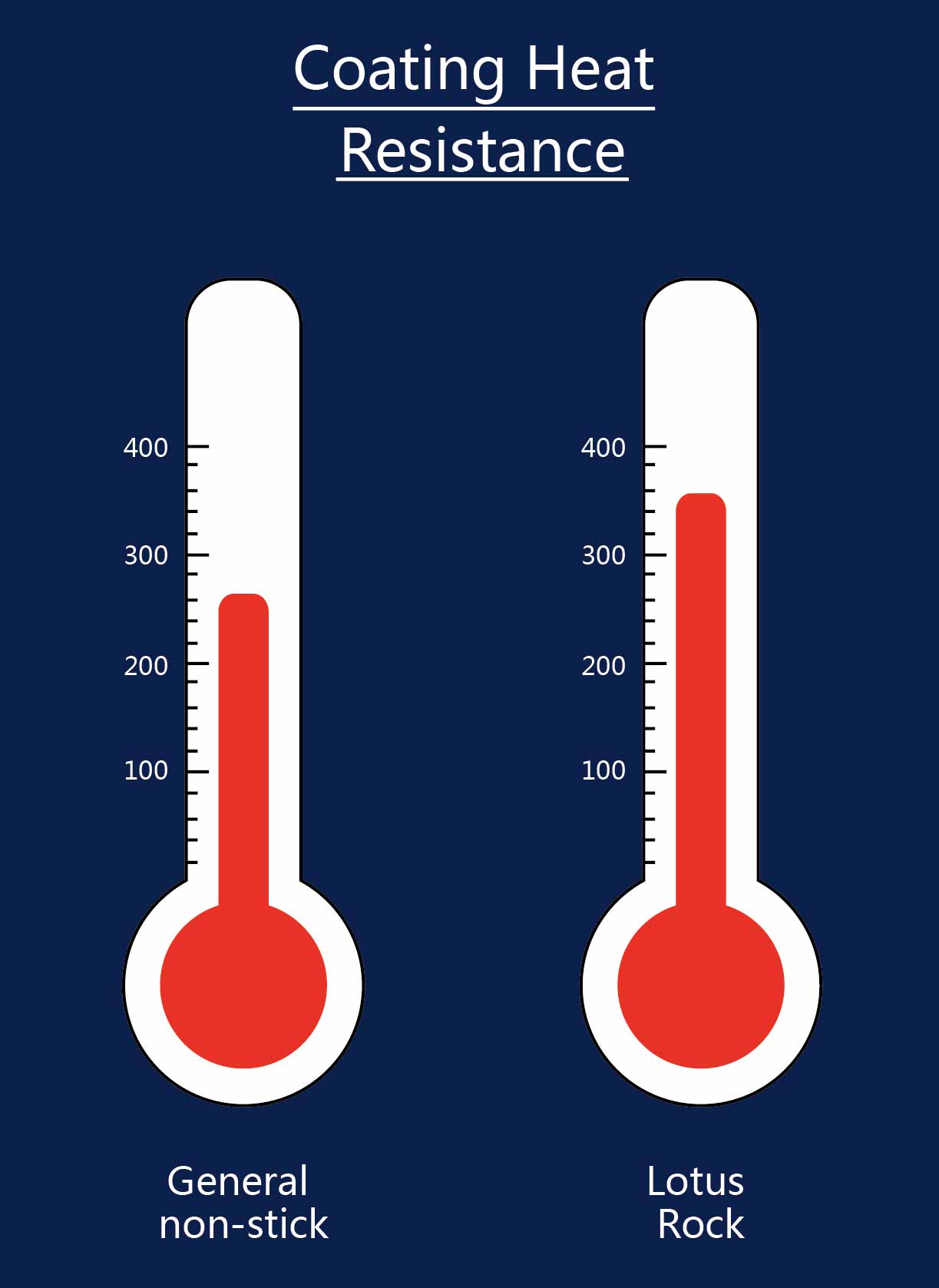

Unlike non-stick coated stir woks, a Lotus Rock stir wok has very high heat resistance (it can reach temperatures of 350 degrees centigrate, in contrast a non-stick coating generally starts to expire around 260 degrees centigrade). For excellent stir frying a wok should be heated gradually so that it reaches a very high temperature just before the oil, raw vegetables and meat are added. It is only with a hot wok that the flavour and tastes of Wok Hei can be imparted on food during stir frying.

Easy and safe handling is essential for proper stir frying, especially when cooking over a very high heat to create the flavours associated with Wok Hei. While a cast iron wok can be cumbersome and difficult to lift, a Lotus Rock wok is thick enough not to warp easily under high heat but is still not so heavy that the wok can be lifted to toss ingredients quickly.

For an excellent stir fry, to impart delicious flavours such as Wok Hei, the wok must maintain a high heat at all times. The various different ingredients for the stir fry, whether it is a protein, vegetable or aromatic should never stream in their own juices, but instead be seared to impart a special caramelized and smoky flavor. In contrast to stainless steel, which takes a long time to heat up and cool down, all Lotus Rock woks are made with heavy gauge carbon steel, which is excellent at absorbing and retaining heat for an all-round excellent, stir-fry Wok Hei effect.

August 18, 2025 / arnoldtnn / 0 Comments

In association with the Davis & Waddell Asia One range, Lotus Rock stir woks are now sold throughout Australia in a number of store outlets, such as Kitchen Warehouse. Currently these stir woks are sold in two different sizes, 12″ and 14″, both of which have the Acacia square wooden handle.

In association with the Davis & Waddell Asia One range, Lotus Rock stir woks are now sold throughout Australia in a number of store outlets, such as Kitchen Warehouse. Currently these stir woks are sold in two different sizes, 12″ and 14″, both of which have the Acacia square wooden handle.

A Lotus Rock wok is a highly versatile cooking utensil. In addition to being excellent for stir frying, a Lotus Rock wok can also be used for a number of other cooking techniques, these include steaming, smoking and deep fat frying.

July 20, 2025 / arnoldtnn / 0 Comments

In Japanese cuisine rolled omelettes are made as rectangular thin omelettes and then rolled into a cylindrical or elongated cube shape using Japanese kitchen chopsticks. To obtain a roll with a constant diameter over the entire lengths, the thin omelette should be of rectangular shape. To obtain this shape a special rectangular frying pan is used. This type of pan shape for making Japanese-style rolled omelettes is generally called Makiyakinabe, but in other parts of Japan it is also known as tamagoyakiki.

In the market place today the Makiyakinabe pan is most often made of iron, with either a plastic or wooden handle. Since the main purpose of Makiyakinabe is to use a lot of eggs to make an omelette, a non-stick coating is applied to the pan to facilitate easy rolling of the omelette into an elongated cube shape.

Generally the ingredients for a Japenese-style rolled omelette with the Makiyakinabe pan are as follows:

- 4 eggs

- soy sauce

- mirin

- sugar

- salt

- cooking oil

To prepare a Japanese-style rolled omelette the eggs need to be beaten in a bowl, with the soy sauce, mirin, sugar and salt added later to the mix. The Makiyakinabe pan should be brought up to a medium heat and then a small amount of cooking oil should be added. Next the egg mixture is poured into the pan and when it is slightly uncooked should be pushed to the side of the pan. After this another small amount of the egg mix should be added to the pan. Once this has cooked for a bit it can be rolled over the first bit of egg mixture that rolled up the pan earlier. Keep adding the egg in new layers until you have used it all up. Once this is done the omelette can be removed from the pan, and once it cooled can be sliced into thin pieces with a sharp knife.

To prepare a Japanese-style rolled omelette the eggs need to be beaten in a bowl, with the soy sauce, mirin, sugar and salt added later to the mix. The Makiyakinabe pan should be brought up to a medium heat and then a small amount of cooking oil should be added. Next the egg mixture is poured into the pan and when it is slightly uncooked should be pushed to the side of the pan. After this another small amount of the egg mix should be added to the pan. Once this has cooked for a bit it can be rolled over the first bit of egg mixture that rolled up the pan earlier. Keep adding the egg in new layers until you have used it all up. Once this is done the omelette can be removed from the pan, and once it cooled can be sliced into thin pieces with a sharp knife.

As was explained above, most Makiyakinabe pans in the market today are made with iron and come with a general non-stick coating on them. However, if you read several reviews of these pans on Amazon you will note that some of these have received a number of negative comments. Some of these complaints include:

- Scratching, both on the interior and exterior of the pan.

- Rust, in some cases this has appeared after only a few uses.

- Uneven heating, the omelette would cook faster in one section of the pan.

- Poor non-stick release, eggs would stick quite easily even after just 3 times of use.

- Difficult to clean, eggs are difficult to remove from non-stick coating.

As shown in the video here, a Lotus Rock Makiyakinabe pan can cook a Japanese-style rolled omelette extremely well, with no sticking and to a perfect thin, crispy texture. There are a number of reasons for this, these are:

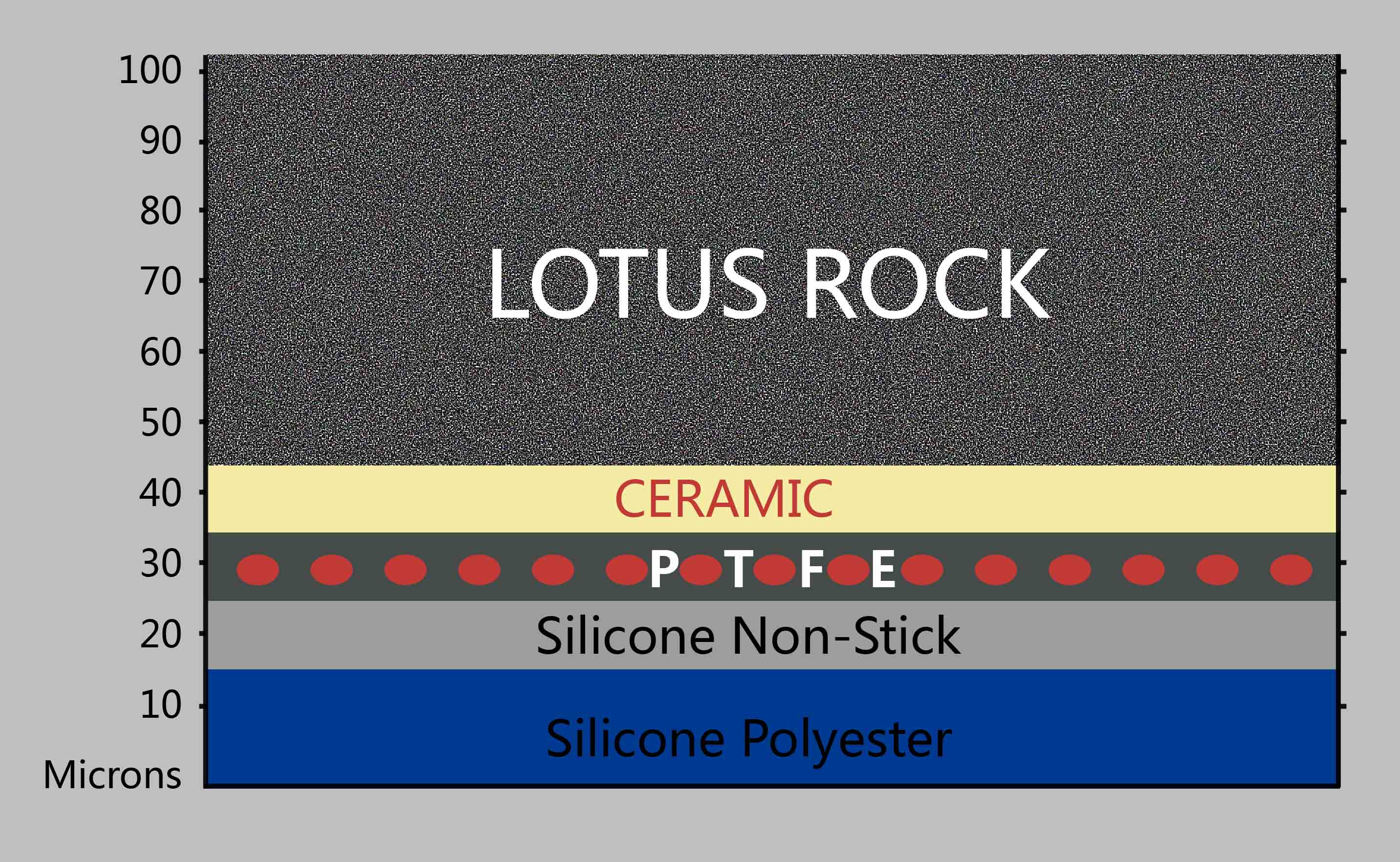

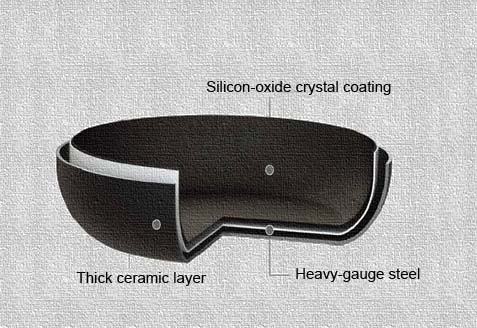

- Thickness. A number of the consumers on Amazon complained about both the thin metal base and non-stick coating. This particular pan did not heat evenly (or retain heat well), and the non-stick coating easily scratched, causing the iron surface below to rust quite easily. As previously explained here, Lotus Rock has both a heavy gauge carbon steel base, as well as a very thick ceramic layer around it (up to 100 microns). Therefore, not only does a Lotus Rock Makiyakinabe pan heat up evenly and quickly for an excellent heating effect, but the coating is extremely scratch resistant to use on the stove top or to whatever material it is being stored on in the kitchen. The thickness of the Lotus Rock ceramic layer also provides excellent corrosion resistance, so no rust spots should appear in spite of intensive, daily use.

- Non-stick release. One of the most common complaints about the pan reviewed on Amazon was that the non-stick effect wore off extremely quickly. In contrast, all Lotus Rock pans have a natural, highly durable non-stick release. As explained above, one of the cooking instructions for all Japanese-style rolled omelettes is that after the egg mixture is rolled up the pan cooking oil should be added again to make the next layer of the omelette. As the video above clearly demonstrates, no sticking occurred when the egg mixture was added to the Lotus Rock Makiyakinabe pan. The high durability of the Lotus Rock natural non-stick surface is perfect for a consumer who wants to use this type of pan on a daily basis for breakfast.

- Metal utensil safe. In order to cook a Japanese-style rolled omelette correctly, speed of movement is important. A tough and sharp utensil is needed to get quickly underneath the egg mixture to roll it over so it settles nicely at the top of the pan. For the pan reviewed on Amazon a fair number of consumers complained that they had to be careful which type of utensil they used, otherwise they might scratch and then impair the quality of the coating. On the other hand for a Lotus Rock Makiyankinabe pan, because the silicon-oxide crystal coating is extremely thin, no metal utensils can damage it or the thick ceramic layer it is coated on. Therefore, a consumer can use any type of utensil, such as a metal spatula, fork or chopsticks without any fear that using them might scratch the coating.

If you are a passionate lover of Japanese cuisine, and you would like to cook a delicious Japanese-style rolled omelette then perhaps you should consider to purchase a Lotus Rock Makiyakinabe pan. It can be used for your daily breakfast, over a long period of time without any worries over scratching or poor non-stick release.

July 13, 2025 / arnoldtnn / 2 Comments

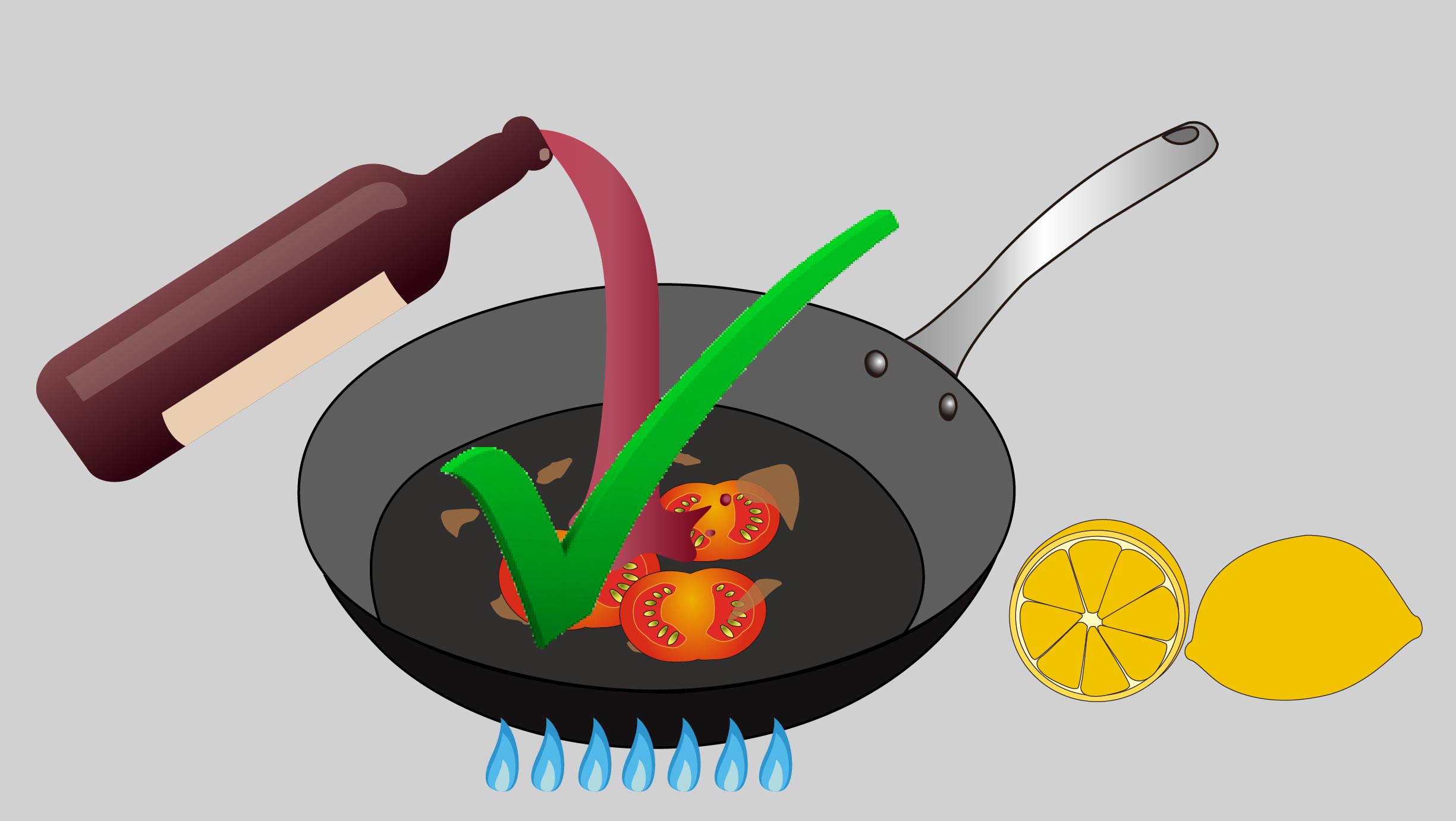

When a consumer is searching for a cooking utensil to buy, one of the many questions they might ask themselves is ‘What kind of cooking task do I want to do?’ Naturally their first consideration would be the pan shape, for example a sauté pan, with its high, straight sides has quite an advantageous shape for high heat searing and then for braising afterwards. The consumer might then consider the thermal properties of the material in the pan (as discussed previously here). Once both of these have been fully evaluated, a fairly experienced chef might also look into the reactivity of the pan’s surface.

The terms “reactive” and “non-reactive” refer to the type of metal from which the cooking utensil is made. Generally speaking, aluminum, cast iron, and copper are all “reactive.” Stainless steel, ceramic, glass and metal cookware with enamel coating are all “non-reactive.” Those metals listed as “reactive” will all generally react with acidic and alkaline foods, but they are all a good choice for boiling water, sautéing vegetables, or searing meat. Acidic ingredients that metals such as aluminum will react with include tomatoes or lemon juice, which give your food a metallic flavor, especially if the cooking time is very long. In addition, with a reactive cooking surface cooking with acidic ingredients might also produce undesirable colours and/or flavours.

Reactive cookware

Aluminum

Tomato sauce and other tomato products react with aluminum because of their acidity, and acids don’t mix well with aluminum. Highly acidic foods cause oxidation, which can darken the aluminum pan and alter the taste of the food. A special case is anodized aluminum, which is aluminum that has been treated with an electrolytic process to create a harder surface that is still somewhat reactive, but significantly less so than untreated aluminum.

Tomato sauce and other tomato products react with aluminum because of their acidity, and acids don’t mix well with aluminum. Highly acidic foods cause oxidation, which can darken the aluminum pan and alter the taste of the food. A special case is anodized aluminum, which is aluminum that has been treated with an electrolytic process to create a harder surface that is still somewhat reactive, but significantly less so than untreated aluminum.

Cast Iron

If food is cooked with this type of cookware then it may pick up chemical elements from the surface. However, ingesting iron is not a health concern as the human body can process iron relatively easy. When properly seasoned a cast iron pan’s surface becomes less reactive and some acidic ingredients can be used for a short period of time. However, these pans must be continually re-seasoned otherwise the surface will become more reactive and begin to discolour and pit when used with acidic ingredients.

If food is cooked with this type of cookware then it may pick up chemical elements from the surface. However, ingesting iron is not a health concern as the human body can process iron relatively easy. When properly seasoned a cast iron pan’s surface becomes less reactive and some acidic ingredients can be used for a short period of time. However, these pans must be continually re-seasoned otherwise the surface will become more reactive and begin to discolour and pit when used with acidic ingredients.

Copper

An uncoated copper surface is actually beneficial for some cooking techniques, such as whipping egg whites (makes the whites more stable). However, unlike iron, the human body has a much harder time eliminating copper after ingesting it, so a cookware utensil with this type of surface should be used sparingly. Other problems with copper cookware include discoloring and scratching.

An uncoated copper surface is actually beneficial for some cooking techniques, such as whipping egg whites (makes the whites more stable). However, unlike iron, the human body has a much harder time eliminating copper after ingesting it, so a cookware utensil with this type of surface should be used sparingly. Other problems with copper cookware include discoloring and scratching.

Non-reactive cookware

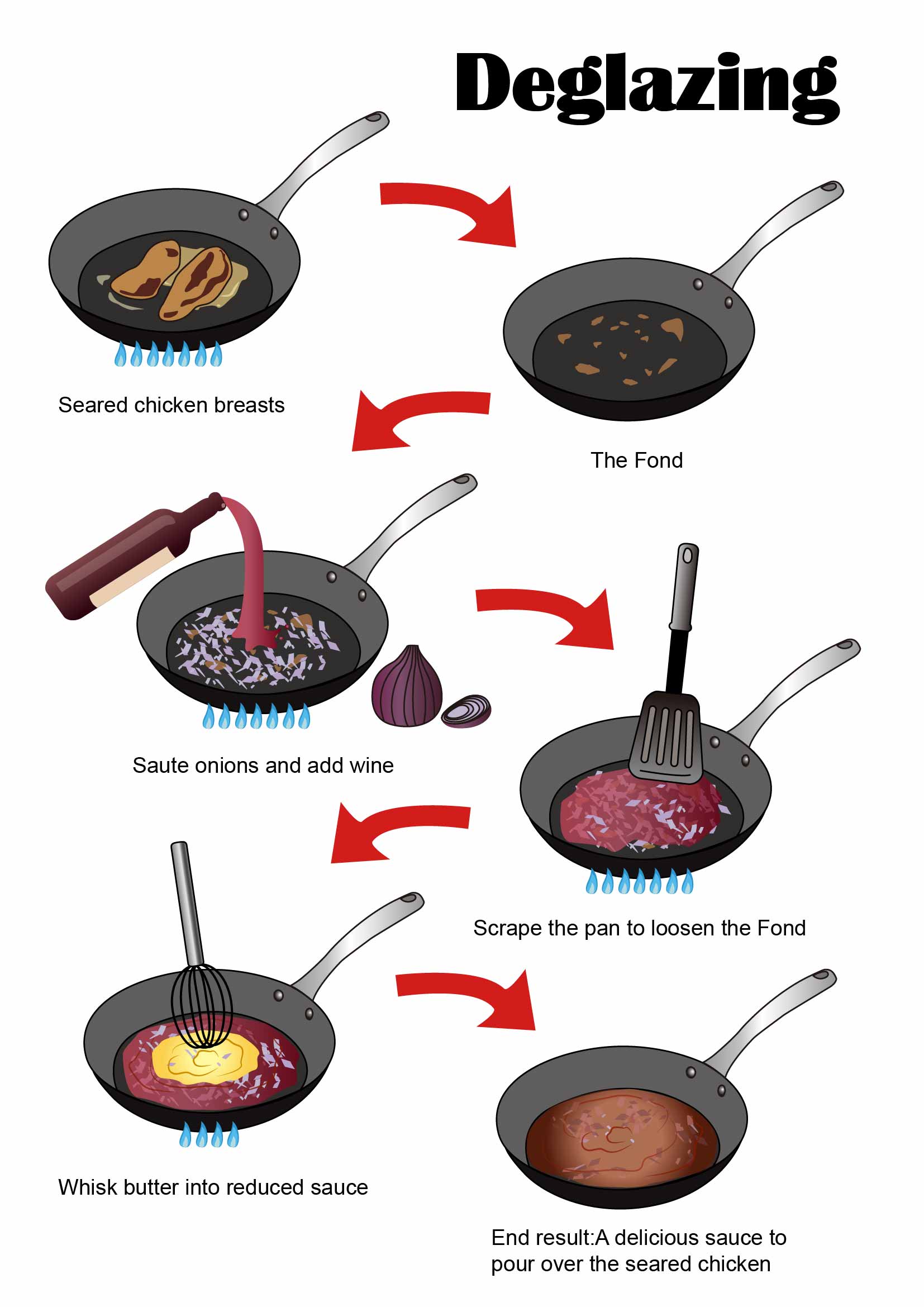

Non-Stick coating

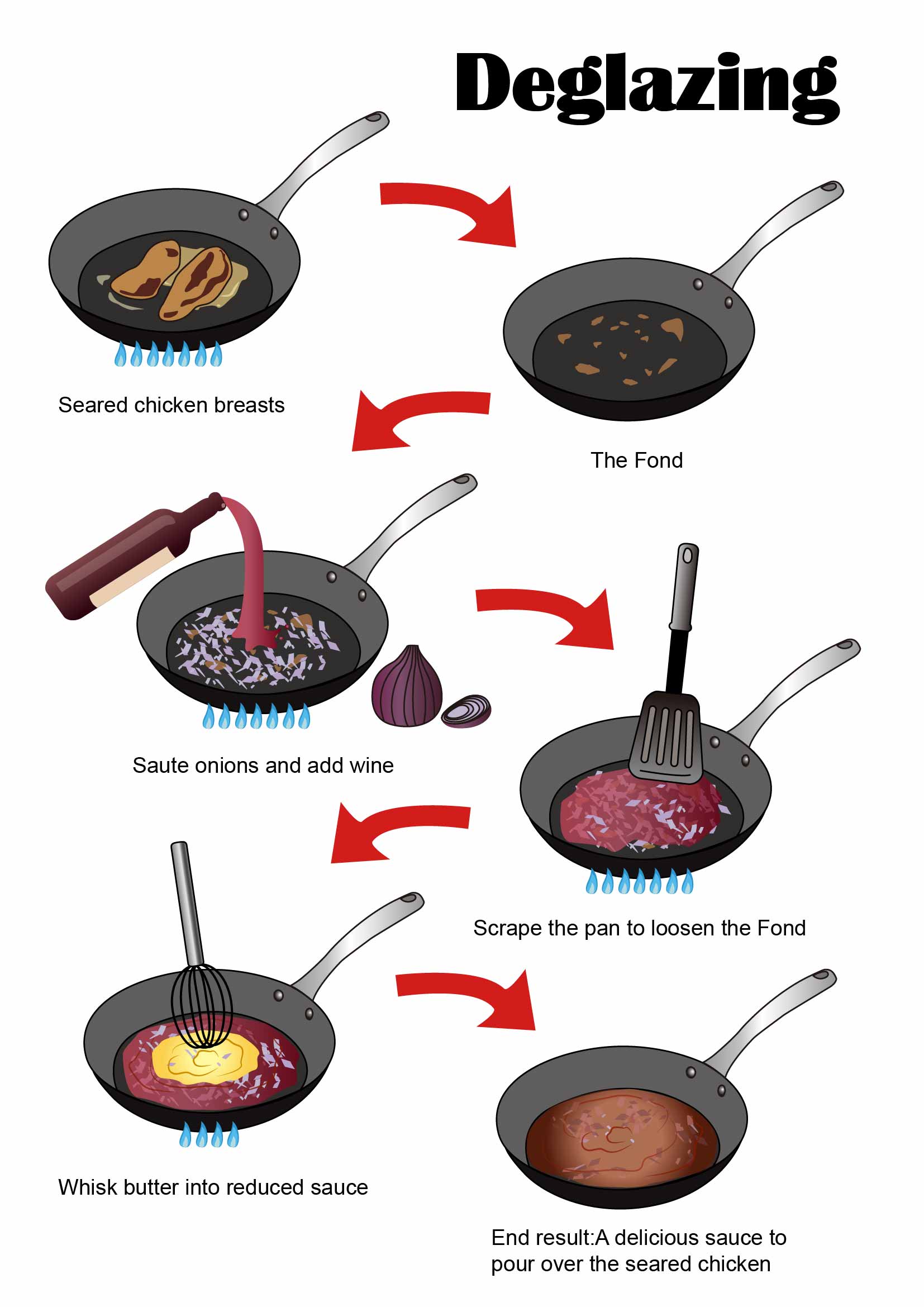

One significant benefit of a non-stick coating on, for example, an aluminum pan, is that it provides a complete non-reactive surface for cooking. Whether the coating contains PTFE or silicone oil for its non-stick release, acidic or alkali ingredients will not react with either the inert coating or the surface metal below it. However, there is one major disadvantage with the non-reactive surface of a non-stick coating: it is not suitable for deglazing. First and foremost, non-stick coatings are not appropriate to use for high heat cooking, which is important for browning meat and vegetables. However, even if a non-stick coating was used for searing large cuts of meat with a brown crust on them, de-glazing can still not be done because these little brown bits formed after the meat is seared will not stick to the pan during cooking. It is these leftover bits on the pan (the fond) which are an essential ingredient for de-glazing, to create a delicious sauce which can then be poured over the just seared meat.

One significant benefit of a non-stick coating on, for example, an aluminum pan, is that it provides a complete non-reactive surface for cooking. Whether the coating contains PTFE or silicone oil for its non-stick release, acidic or alkali ingredients will not react with either the inert coating or the surface metal below it. However, there is one major disadvantage with the non-reactive surface of a non-stick coating: it is not suitable for deglazing. First and foremost, non-stick coatings are not appropriate to use for high heat cooking, which is important for browning meat and vegetables. However, even if a non-stick coating was used for searing large cuts of meat with a brown crust on them, de-glazing can still not be done because these little brown bits formed after the meat is seared will not stick to the pan during cooking. It is these leftover bits on the pan (the fond) which are an essential ingredient for de-glazing, to create a delicious sauce which can then be poured over the just seared meat.

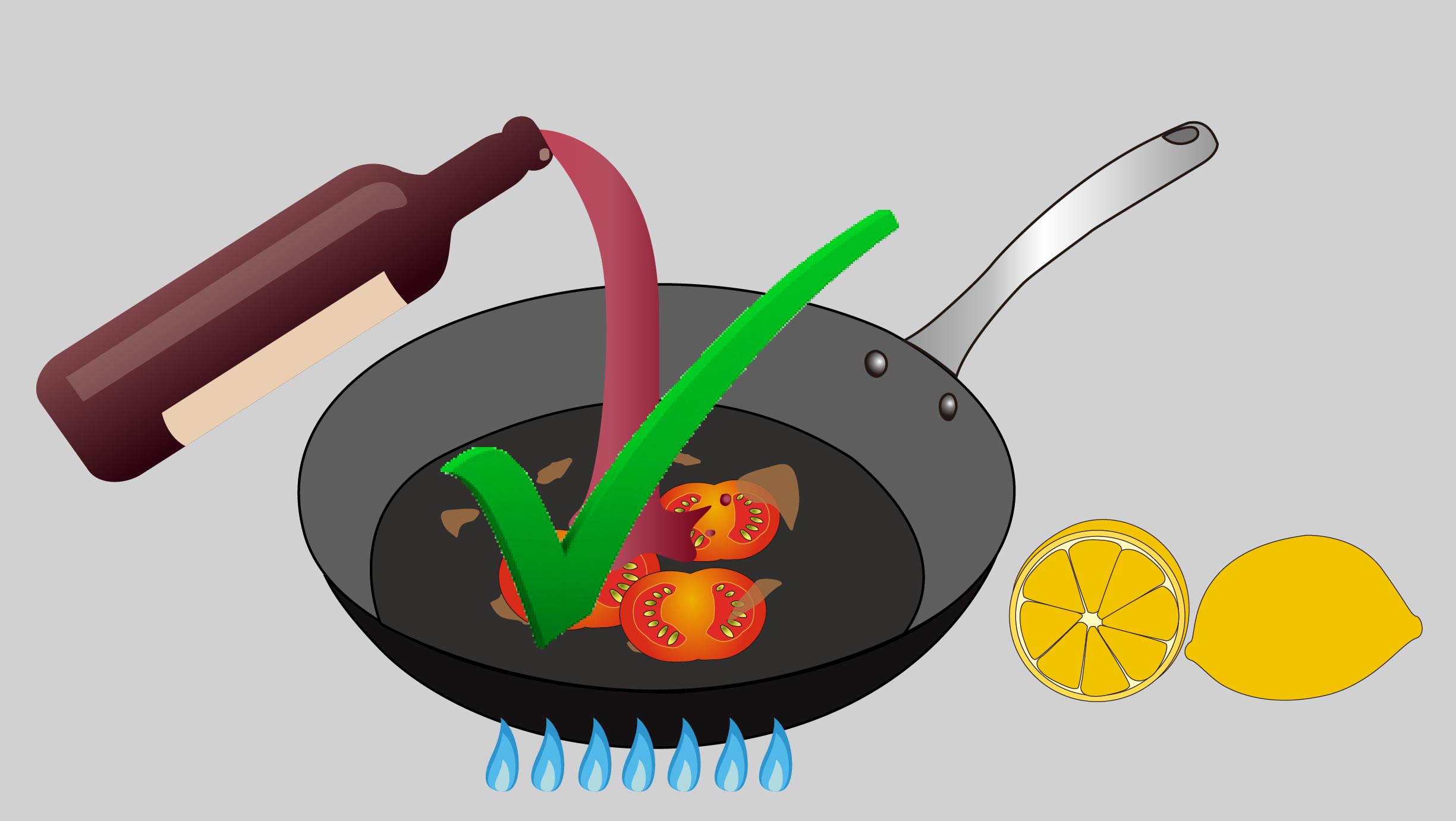

Lotus Rock

All Lotus Rock pans come with a non-reactive surface. This means that during cooking certain ingredients, usually acidic ones, will not chemically combine and alter the flavor and colour of the finished palette. For example, tomato juice can be used for a Bolognese sauce and lemon juice can be added where necessary to give a dish extra flavor. These sauces can then be cleaned from the pan after cooking without any colour staining or visible scarring on the coating’s surface. Unlike cast iron, a Lotus Rock pan does not need to be continually re-seasoned to make it less reactive to acidic ingredients. Likewise, unlike a copper pan, Lotus Rock can be used on a regular basis without heavy metals being absorbed into the cooked food. Lastly, because of its non-reactive surface, a Lotus Rock pan is highly appropriate for de-glazing after meat has been seared at a high temperature. The residue of the Fond can be made to form part of a delicious sauce through the addition of some kind of acidic solution, such as a broth or cup of wine.

All Lotus Rock pans come with a non-reactive surface. This means that during cooking certain ingredients, usually acidic ones, will not chemically combine and alter the flavor and colour of the finished palette. For example, tomato juice can be used for a Bolognese sauce and lemon juice can be added where necessary to give a dish extra flavor. These sauces can then be cleaned from the pan after cooking without any colour staining or visible scarring on the coating’s surface. Unlike cast iron, a Lotus Rock pan does not need to be continually re-seasoned to make it less reactive to acidic ingredients. Likewise, unlike a copper pan, Lotus Rock can be used on a regular basis without heavy metals being absorbed into the cooked food. Lastly, because of its non-reactive surface, a Lotus Rock pan is highly appropriate for de-glazing after meat has been seared at a high temperature. The residue of the Fond can be made to form part of a delicious sauce through the addition of some kind of acidic solution, such as a broth or cup of wine.

June 3, 2025 / arnoldtnn / 0 Comments

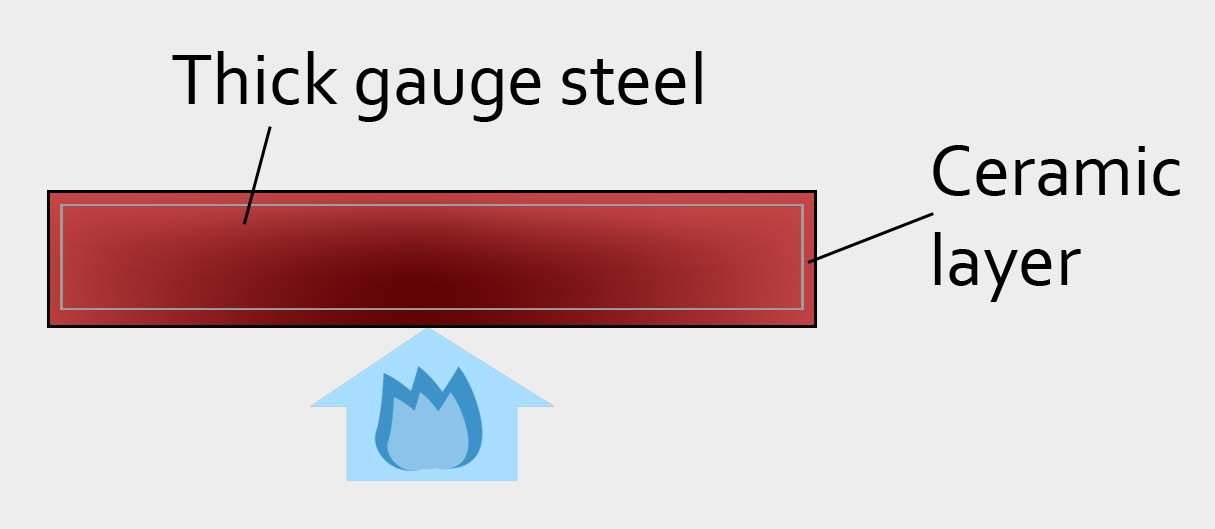

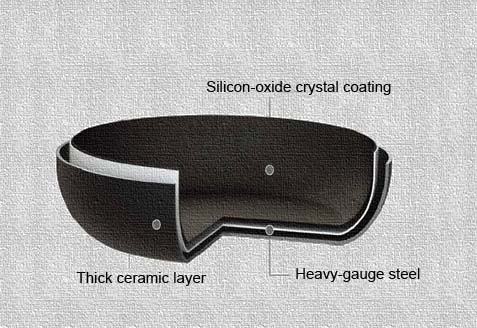

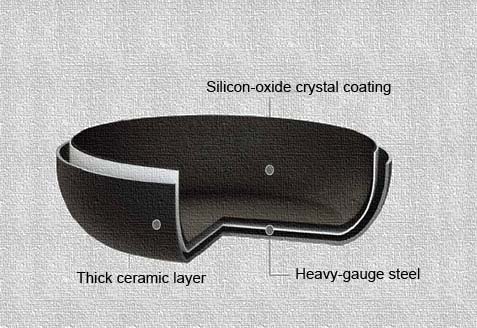

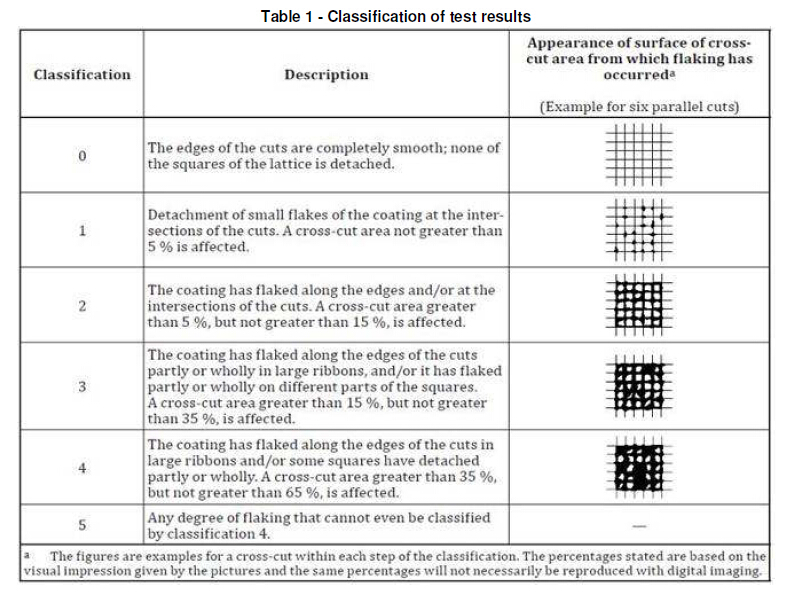

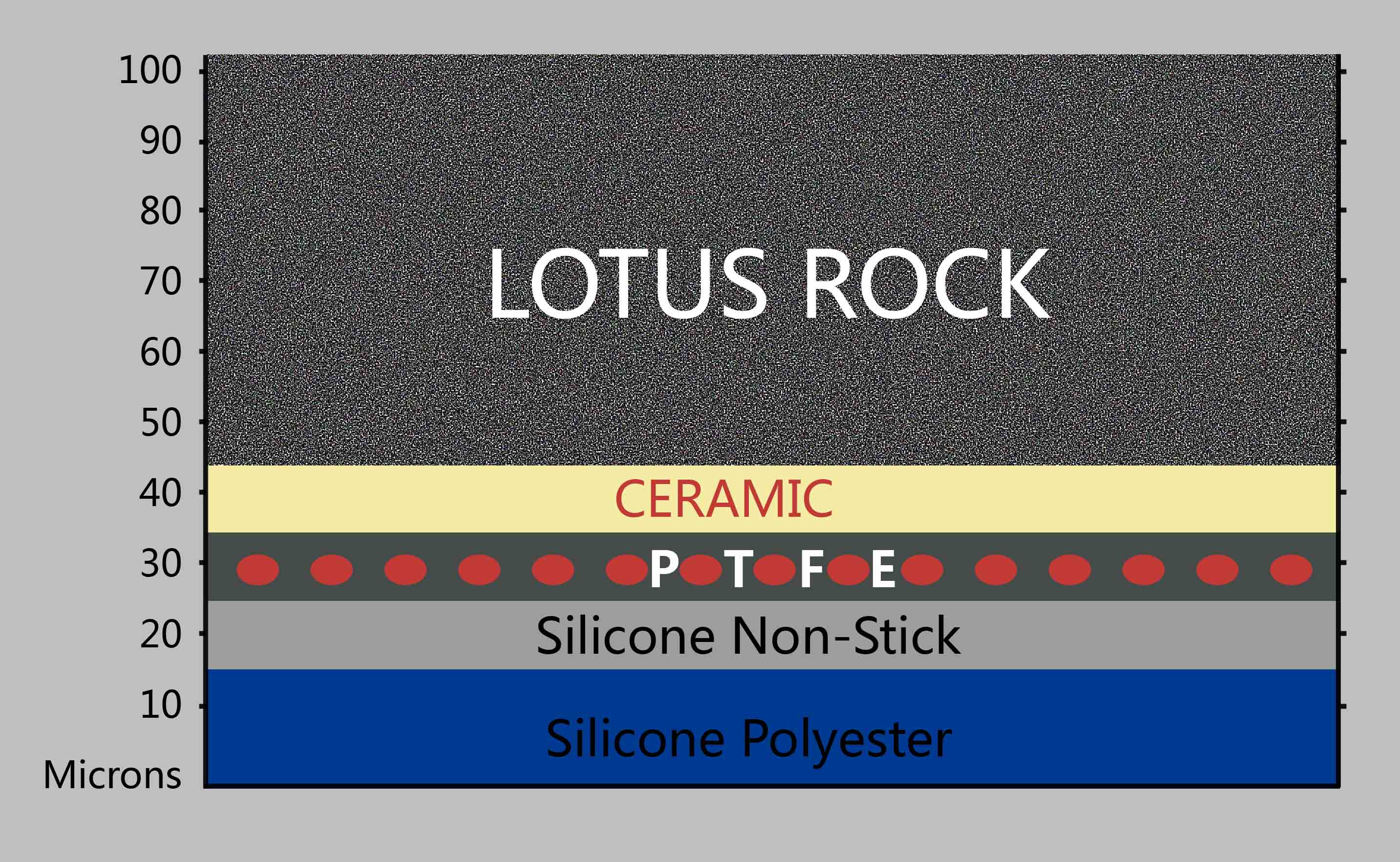

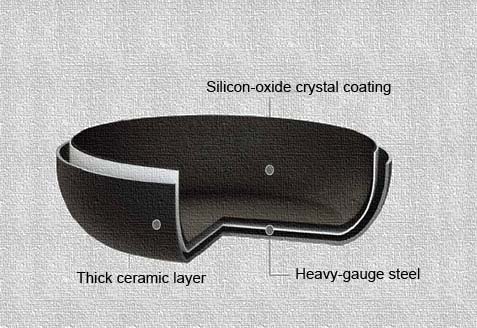

Quite often when a consumer considers the features of the coating for a Lotus Rock pan they might be impressed that it is metal utensil safe, or alternatively that it has very high heat and abrasion resistance. What they may not appreciate as much is the actual thickness of the Lotus Rock coating and the advantages that come with it. As you can see in the chart below, when compared to other commonly used non-stick coatings, Lotus Rock’s hard ceramic coating is quite considerably thicker. Even compared to a sol-gel enamel coating, which is often advertised on the market for its strong, thick construction, the Lotus Rock coating is more than twice as thick.

There are a number of significant advantages to a cookware utensil having a thick coating. First, it improves the heating effect of the pan. Most pots and pans on the market are either just a metal such as cast iron or stainless steel, or they have a metal substrate with a coating. For a cookware utensil the metal’s main purpose is for heat conduction; when the pan is heated the atoms within the metal lattice structure bounce into each other and thus pass on energy from the stove directly to the food. The two main benefits of a coating is to protect the pan from oxidation, and provide some non-stick release for easier cooking and cleaning. However, whether they are coated or not coated what a lot of these pans lack is the ability to retain heat within the pan. One way to improve the heat retention of a cookware utensil is increase the thickness of the metal, for instance, as explained here, Lotus Rock is made of heavy gauge 2.0mm steel, which with is highly dense carbon steel structure is much better than a metal such as aluminum at holding on to heat. But yet, with a Lotus Rock pan, its heat retention is further improved because of the highly thick ceramic layer of 100 microns on it. The thick ceramic layer acts as an insulator around the pan, which is highly beneficial for high heat cooking techniques such searing, sautéing, stir frying, barbecuing, and grilling that require a hot pan, which doesn’t suddenly drop in temperature when the food is added.

Another important consideration which is often overlooked when considering the thickness of a coating for a pan is the exterior coating. A lot of cookware manufacturers, when they label that their pan has a coating thickness of 45 microns, often neglect to mention that this is only for the interior of the pan. Most often in order to save on cost, the exterior of cookware is sprayed with a silicone polyester coating, which is rarely thicker than 15 microns. This has very little effect on heat dispersion or retention for a pan and is purely there just to protect the pan from the atmosphere around it. With a Lotus Rock pan on the other hand, it has the same thickness on the interior and exterior of the pan. So quite often a general non-stick pan, when you add together both the interior and exterior coating, does not exceed a thickness of 50 microns. Whereas a Lotus Rock pan always has a thickness of around 200 microns, which is four times thicker than the average non-stick pan.

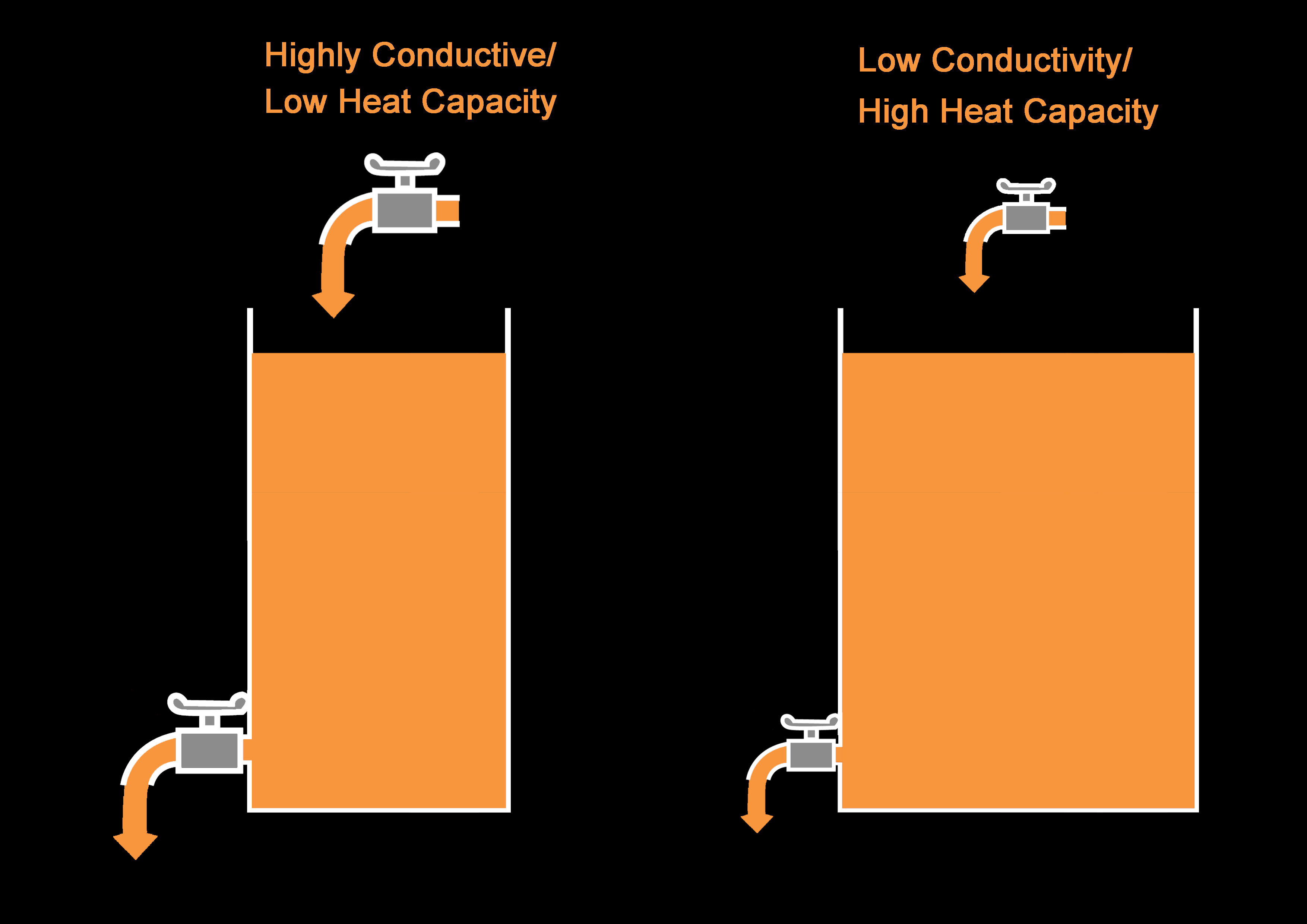

In addition to heat retention, a thicker coating is also advantageous for use with induction cooking top surfaces. This is because the main difficulty a lot of pans have with this type of cooking top surface is over-heating. Induction transmits heat incredibly efficiently, which for many pans can cause the metal to over-heat and deform. Or alternatively, the over-heating can cause burnt marks on the outside of the pan, or scorch the oil or food on the interior. In contrast, the thick exterior coating on a Lotus Rock pan can, because of its poorer electrical conductivity compared to a metal, slow down and disperse the heat travelling through the pan.

Lastly, a thick exterior coating of Lotus Rock protects the pan from general cooking use much better than a pan with a silicone polyester coating. Whether from scratch marks during use on the sharp edges of a gas stove, or just general abrasion that might occur over time and thus erode the coating, a thicker coating will protect the metal substrate from exposure to the atmosphere for a longer period of time.

June 1, 2025 / arnoldtnn / 0 Comments

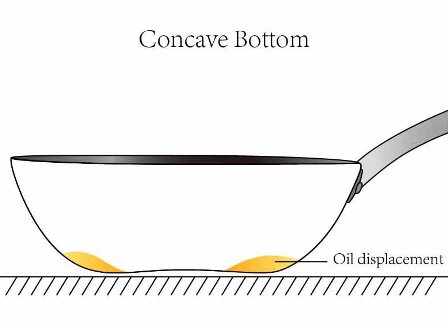

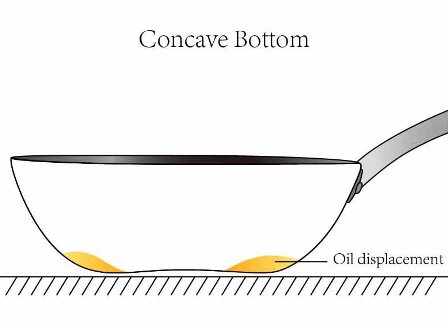

While shopping in a department store, the average consumer may not consider the base concavity of a cooking utensil their most important consideration when they are making a purchasing decision. More likely the price of the item, the look and feel of the surface coating, and perhaps the pan’s weight and appearance are all reasons which a consumer might decide are most important before they buy a cooking utensil, such as a stir wok.

However, if the base of a pan is not made according to the correct specifications then it could become obsolete for cooking use quite quickly, thus negating any benefits that the pan might have had because of its price, material quality or attractive appearance. For example, if the concavity of the pan is set too high then the heat source, from a cooking top surface such as a gas or electric stove, could force the centre of the pan to rise upwards to quite a large extent. Consequently, the pan would then have a bump in the centre which would cause cooking oil and sauces to slide to the edge of the pan.

However, if the base of a pan is not made according to the correct specifications then it could become obsolete for cooking use quite quickly, thus negating any benefits that the pan might have had because of its price, material quality or attractive appearance. For example, if the concavity of the pan is set too high then the heat source, from a cooking top surface such as a gas or electric stove, could force the centre of the pan to rise upwards to quite a large extent. Consequently, the pan would then have a bump in the centre which would cause cooking oil and sauces to slide to the edge of the pan.

Alternatively, another difficulty may arise if the pan concavity is too shallow. This would mean that heat from the stove top would have a stronger effect towards the side of the pan and push the edges of the bottom upwards, which would then create a convex shape at the bottom of the pan. This would not only cause cooking ingredients to congregate in the centre of the pan, and so reduce cooking space, but it would also create a safety hazard as the pan would spin around during cooking.

So, for the reasons stated above, it is essential for the durability of all pots and pans that they have the correct bottom concavity height. If they do not, then whether the pan is made with high quality material or the non-stick coating is excellent becomes irrelevant because either a spinning motion or highly concave pan will develop on the bottom.

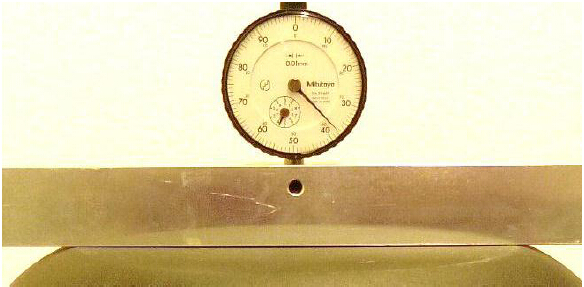

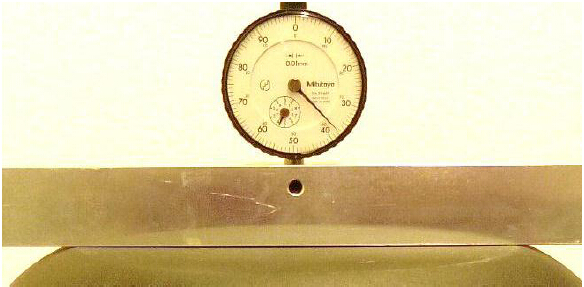

There is a commonly used test in the kitchenware industry to demonstrate whether the concavity of a cookware utensil is correct or not. This test involves turning a pan upside down and placing a specially designed, straight edged measuring instrument across the bottom of the pan. This test requires that the pan’s concavity is measured both before and after it has been heated. The cold condition (room temperature) test stipulates that the pan must have a concavity of between 0.3% – 0.6%. The warm condition test (200 degrees +/- 5 degrees dry heating) specifies that after the pan is heated the bottom must not have a concavity of more than 0.3%.

There is a commonly used test in the kitchenware industry to demonstrate whether the concavity of a cookware utensil is correct or not. This test involves turning a pan upside down and placing a specially designed, straight edged measuring instrument across the bottom of the pan. This test requires that the pan’s concavity is measured both before and after it has been heated. The cold condition (room temperature) test stipulates that the pan must have a concavity of between 0.3% – 0.6%. The warm condition test (200 degrees +/- 5 degrees dry heating) specifies that after the pan is heated the bottom must not have a concavity of more than 0.3%.

The Lotus Rock standard concave required range is between 0.003 – 0.006 thousandths. With a concave base set between these parameters the pan should neither expand too much through the centre, which if it did would cause oil or sauces to settle at the edges of the pan, but neither should a convex shape develop at the bottom, which if it did would create a spinning motion on a flat top cooking surface.

So along with a metal utensil safe surface, a heavy gauge steel substrate, and a PTFE-free lipophilic coating, a Lotus Rock pan will, with the correct base concavity, be a cookware utensil that can be used for a long period of time.

May 21, 2025 / arnoldtnn / 0 Comments

As explained in the previous blog post, Lotus Rock has designed and patented a number of highly eye-catching, ergonomic handles for its various cookware and BBQ items. Handle materials can vary from forged steel, to a natural wood such as acacia or beech, to bakelite with soft-touch coating, and so on a silicone material, molded into a variety of different shapes, such as a lollipop.

As explained in the previous blog post, Lotus Rock has designed and patented a number of highly eye-catching, ergonomic handles for its various cookware and BBQ items. Handle materials can vary from forged steel, to a natural wood such as acacia or beech, to bakelite with soft-touch coating, and so on a silicone material, molded into a variety of different shapes, such as a lollipop.

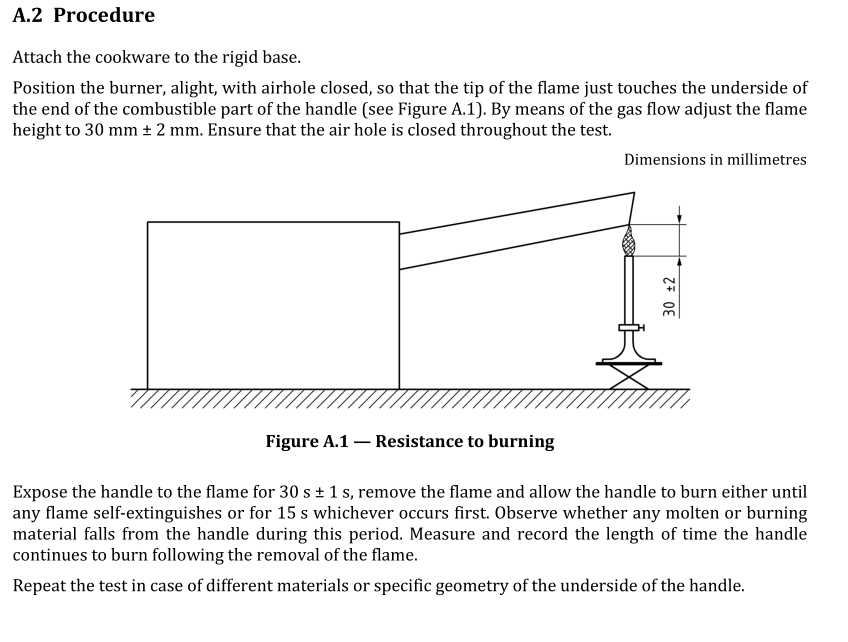

However, for cookware usage a good handle should not just have an attractive appearance or a comfortable, stay-cool grip, it should also be safe to use as well. One particularly important feature for a handle with a Lotus Rock pan is its strength and secure attachment to the pan’s body. All Lotus Rock pans come with a very heavy carbon steel substrate of 2.0mm in thickness. Although not nearly as heavy as cast iron a Lotus Rock pan is still quite a heavy weight for certain types of cooking utensils, such as a 12” stir wok or a 28cm frying pan. Therefore, a strong, well-designed handle is especially important for a safe cooking experience with a Lotus Rock pan.

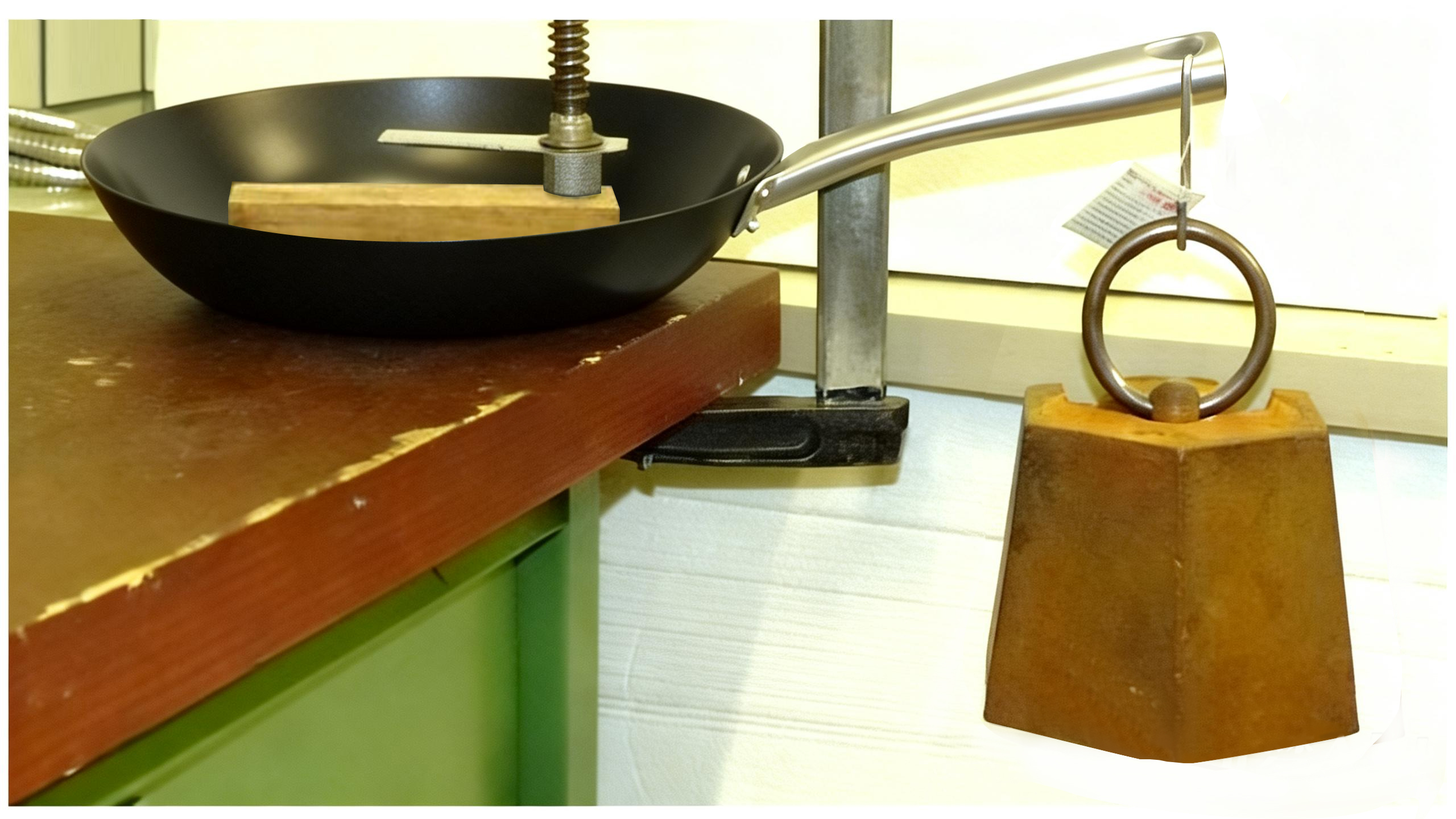

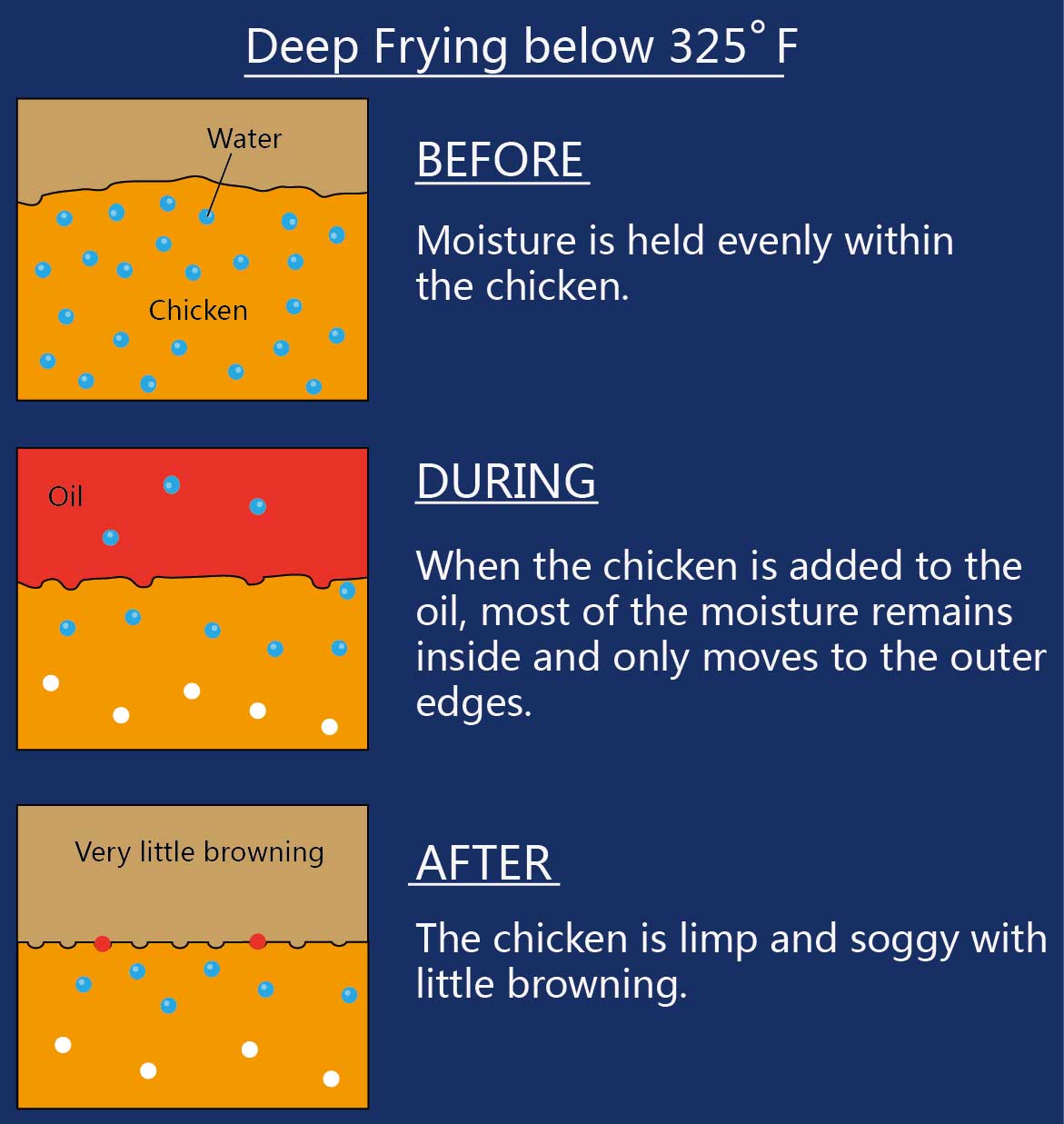

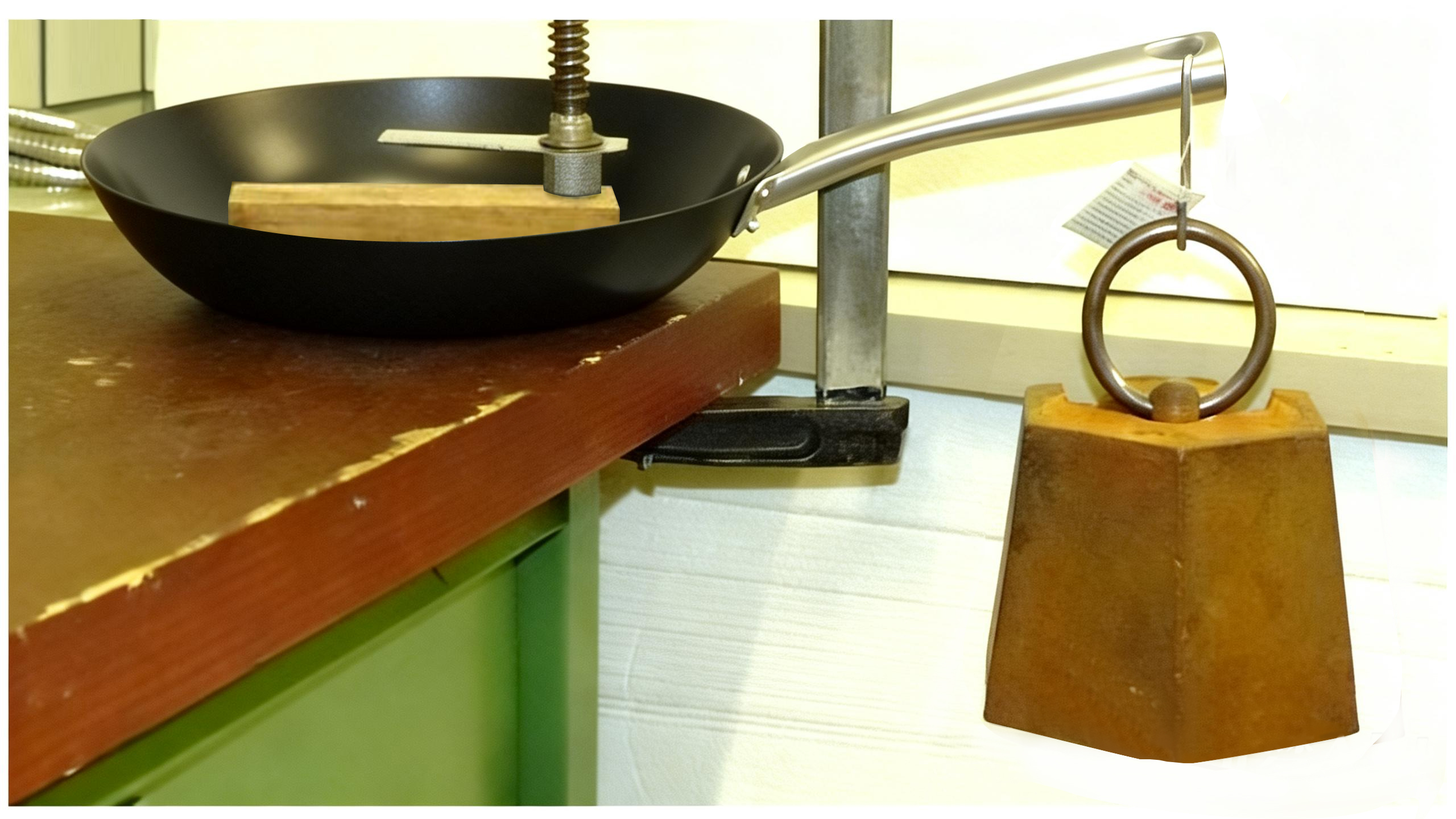

The kitchenware industry commonly uses a bending strength test, from testing standard BS EN 12983/ 7.5, to assess whether a handle is sturdy and strongly attached enough to a pot or pan.

BS EN 12983/ 7.5 Bending Strength Test Procedure

The BS EN 12983/ 7.5 procedure for the Bending Strength Test is as follows:

Lotus Rock Kyoto handle

Lotus Rock Zurich Handle

Since Lotus Rock’s was introduced into the market, a number of different types of handles for Lotus Rock pans have been tested according to the BS EN 12983/ 7.5 bending strength test. As shown in the photos above both the Zurich square wooden handle, which uses a riveted attachment method, and the bakelite handle, which uses a welding attachment method, has been stress tested with a 10kg weight attached firmly to the end of the handle. Both of these handles passed without any recorded major failure at a SQTS (Swiss Quality Testing Services) testing lab.

May 14, 2025 / arnoldtnn / 0 Comments

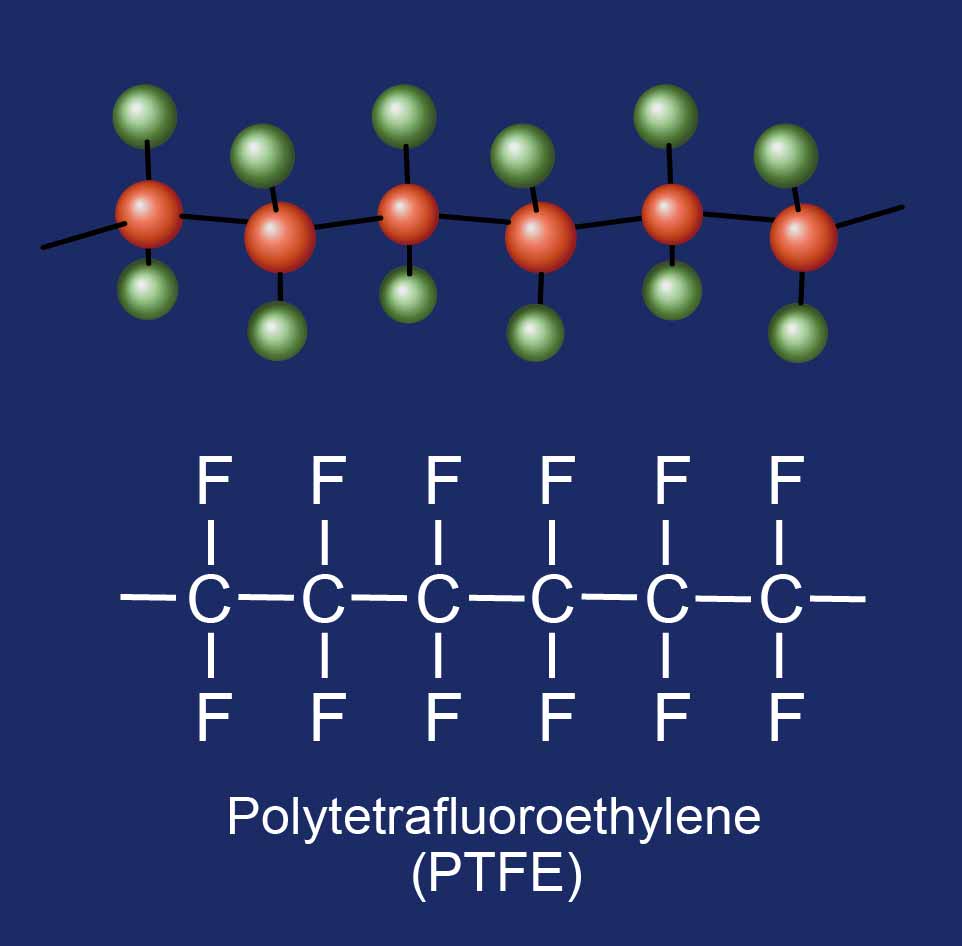

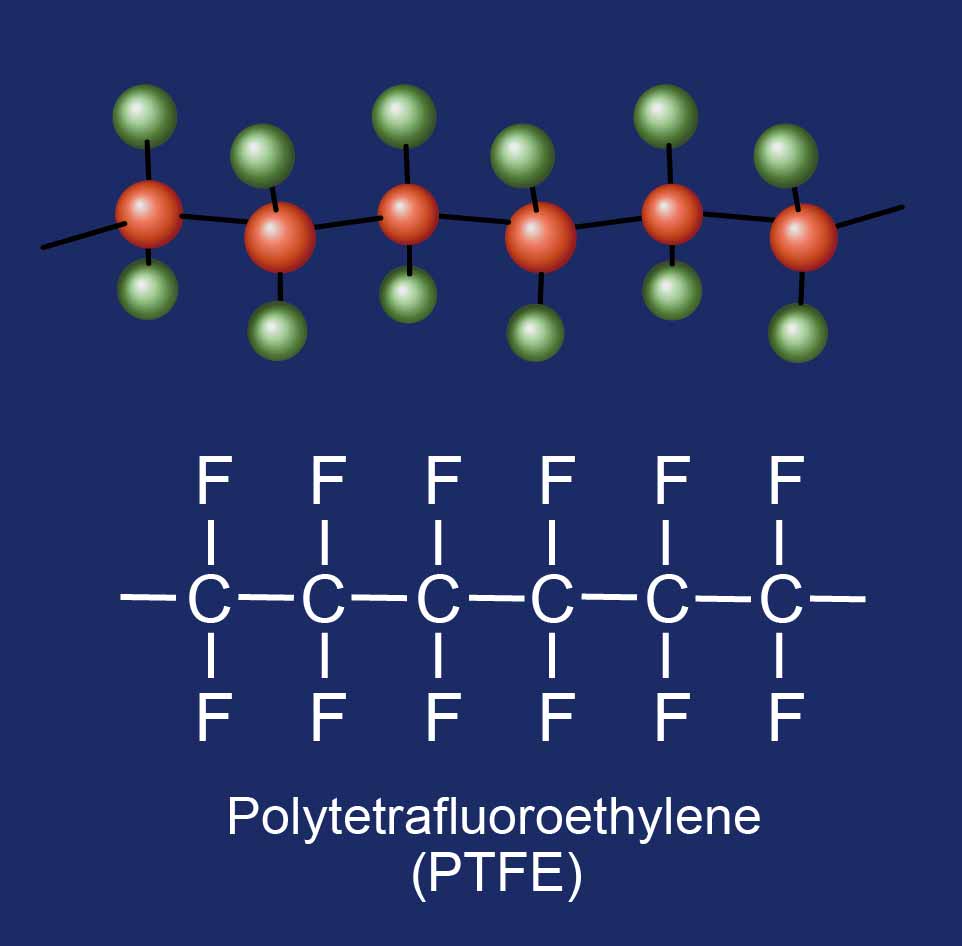

The previous blog post described how a migration test can be done to test the surface reactivity of a cookware pan. The benefit of a non-stick coating on a pan is that it provides a non-reactive surface whereby all kinds of ingredients, whether they are highly acidic or not, can be used for cooking without creating any undesirable colors and/ or flavors. Generally speaking, most non-stick coatings contain a substance called PTFE. This gives the coating its non-stick release and has been proven to have the lowest coefficient of friction (CoF) of any known solid. In other words, the majority of materials do not stick to a PTFE-based non-stick coating. Therefore, because of its excellent non-stick release and non-reactive surface, a PTFE-based non-stick coating should pass a standard BS EN 1186-1: 2002 migration test quite easily.

However, although PTFE- based coatings do undoubtedly provide a highly non-reactive surface for a cookware utensil, they also have some significant disadvantages; one of these is a tendency of PTFE-based non-stick coatings to peel off. Within a non-stick coating PTFE does not bond well to itself, and so by and large it doesn’t have a very stable construction. This weak coating structure is degraded through general scratching with a utensil, and also by rubbing it with a standard abrasive cleaning pad. Moreover, PTFE based coatings are generally quite thin, roughly 15-20 microns in thickness. This thinness makes PTFE-based coatings quite liable to break up and expose the substrate below it, such as aluminum or steel, to foodstuffs or oxygen which could produce some undesirable reactions and damage the quality of the cookware utensil.

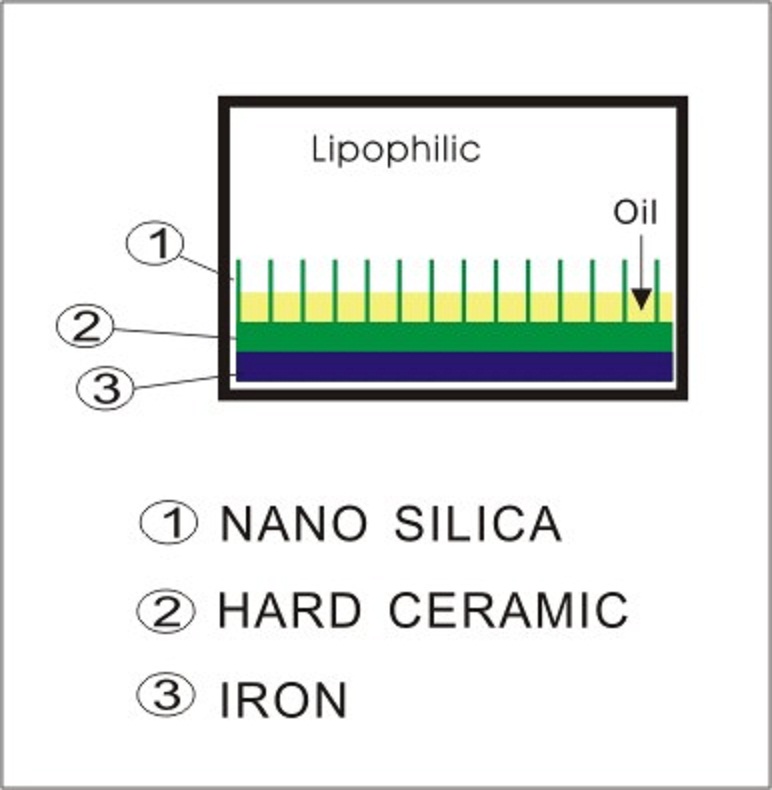

Lotus Rock, on the other hand, contains no PTFE or any other non-stick chemical within its coating. On both the interior and exterior of all Lotus Rock pans is a thick ceramic layer, which is up to 100 microns thick. This not only provides excellent protection to the steel substrate below it, but the strongly bonded construction of the ceramic layer also ensures that all Lotus Rock pans have outstanding scratch and abrasion resistance.

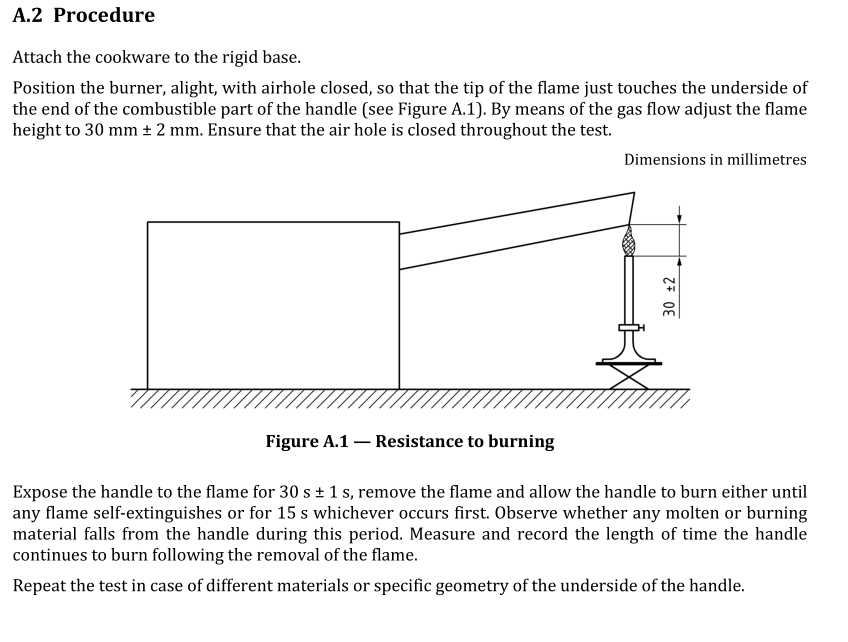

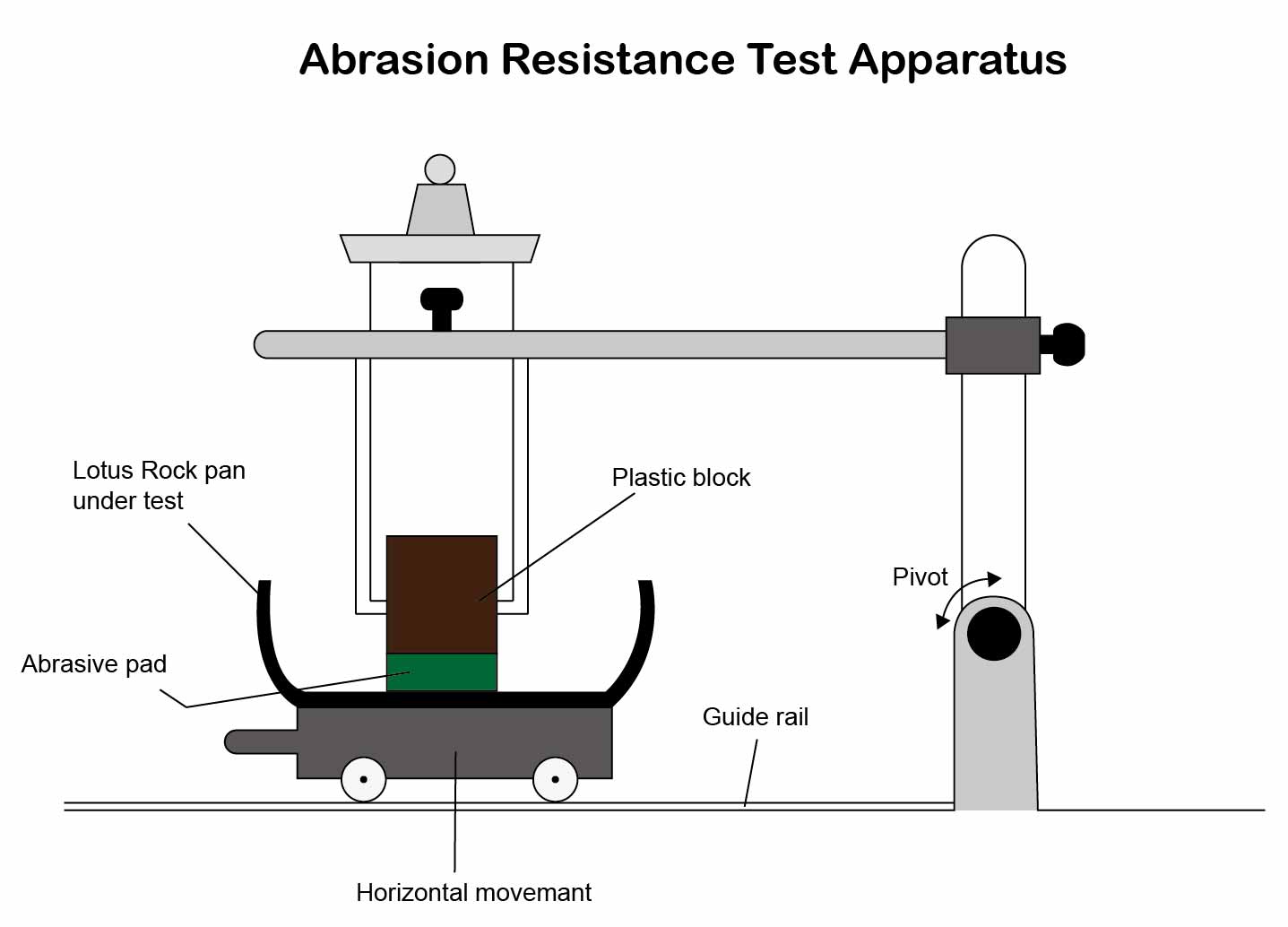

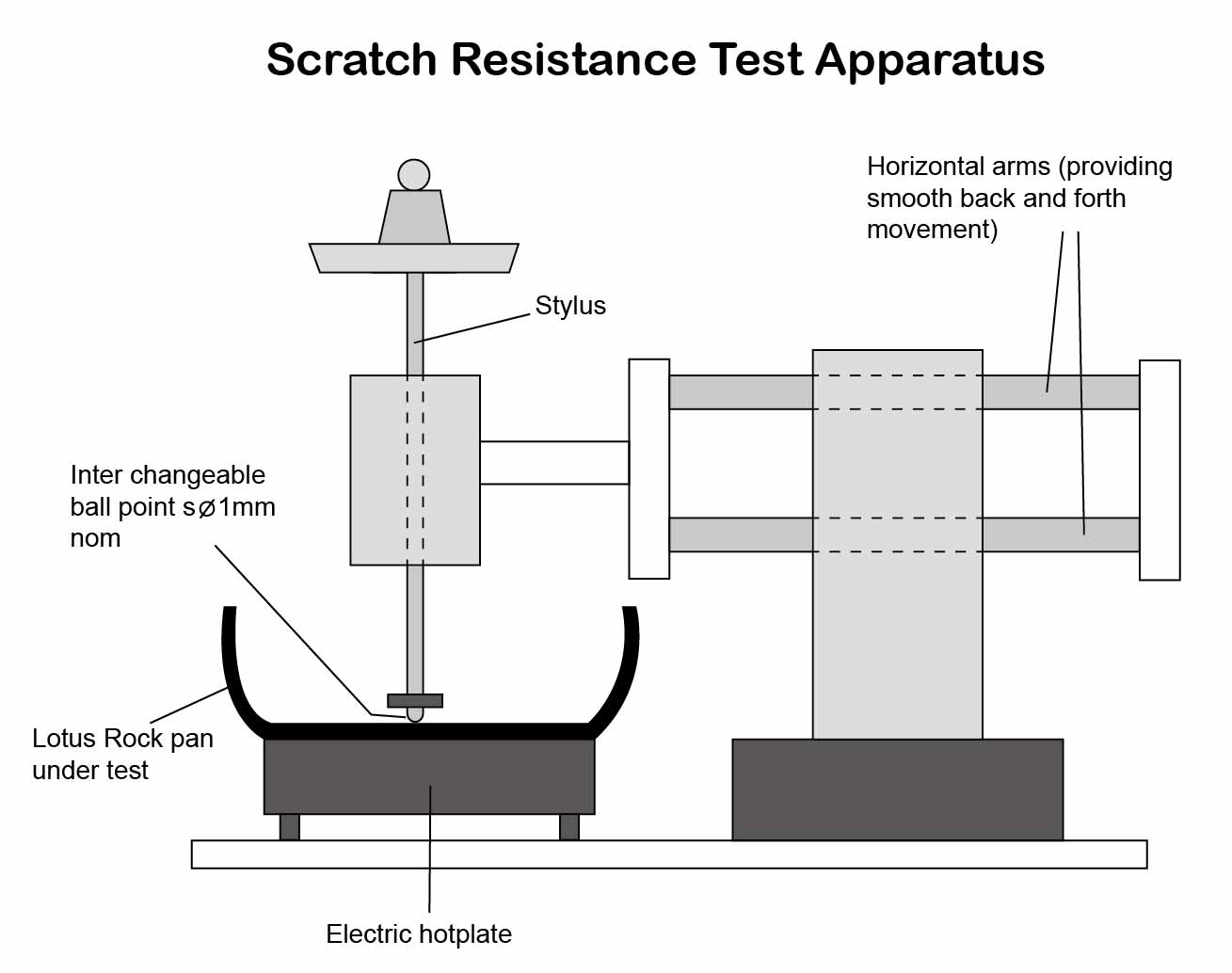

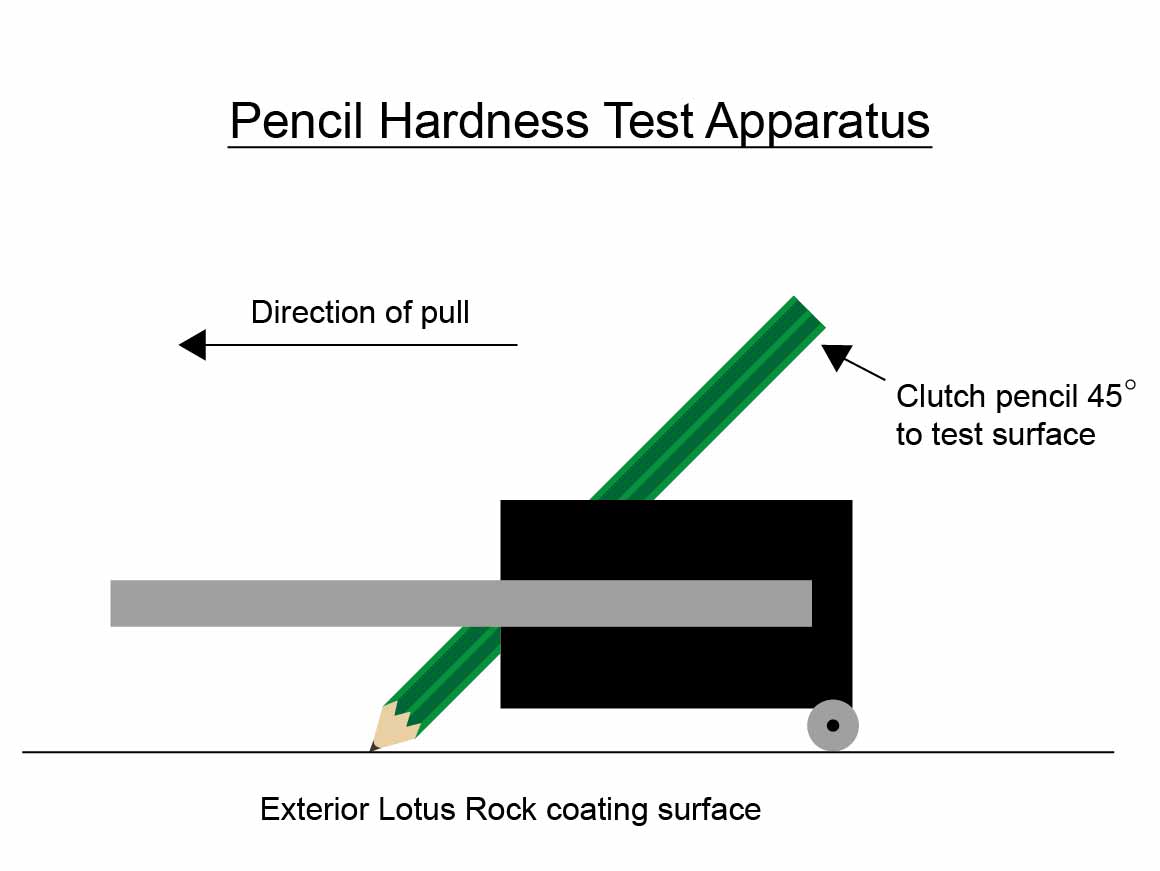

There are two well-known tests within the kitchenware industry, from the BS 7069 : 1988 British Standard Specification for Cookware, which can demonstrate whether or not a cookware utensil has excellent scratch and abrasion resistance. Both of these tests have been used on a Lotus Rock frying pan.

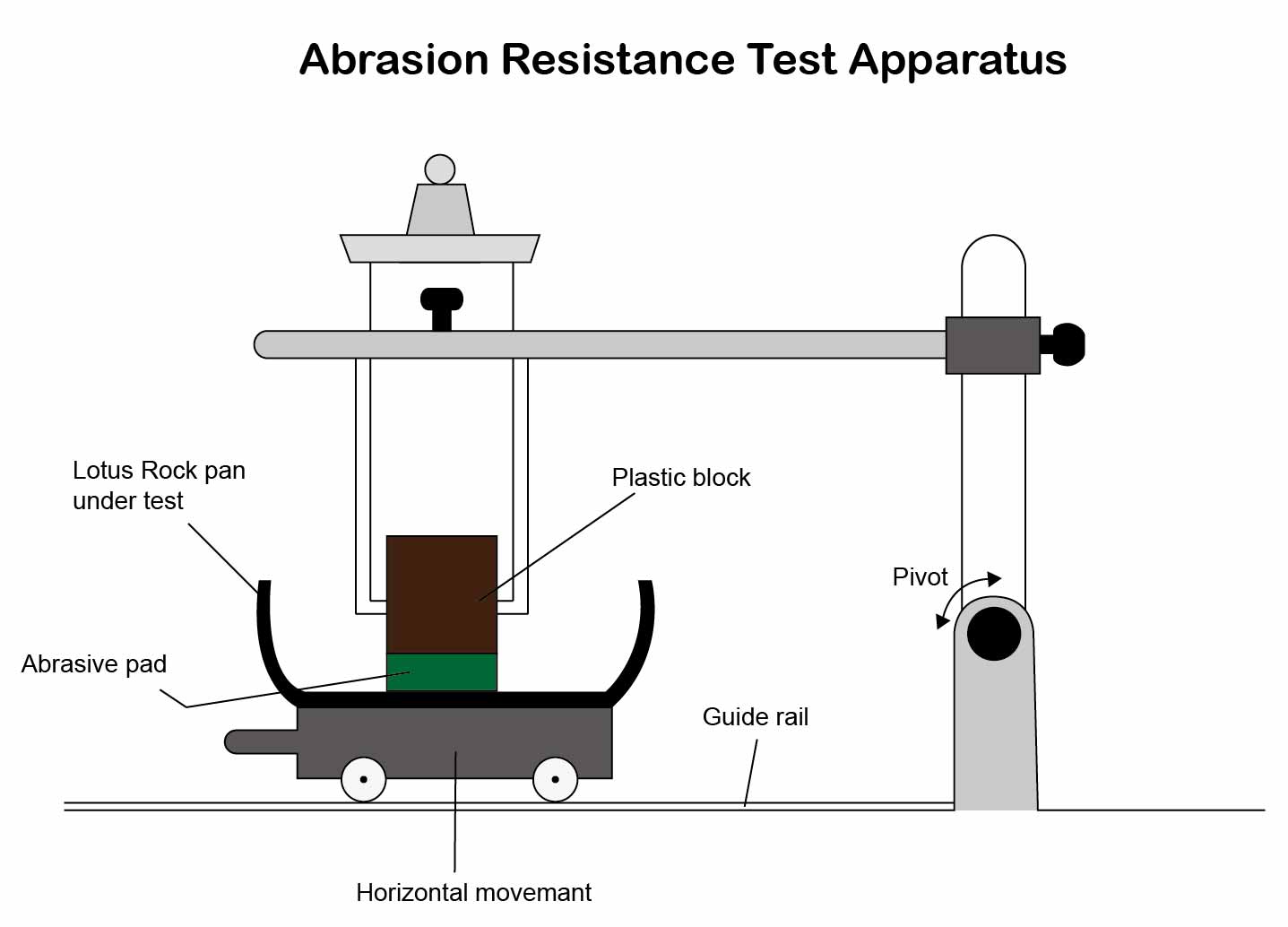

1. BS 7069 Abrasion Resistance Test Procedure

Mount the item of cookware under test rigidity on the reciprocating support and apply the loaded abrasive pad to the non-stick surface, lubricate the surface by the addition of domestic washing-up liquid. Keeping the loaded abrasive pad stationary, move the reciprocating support backwards and forwards over a distance 50mm+2.5mm. Continue for 250 cycles. Renew the abrasive pad at 50 cycle intervals.

SGS test result for Lotus Rock pan = Pass. “No visible damage was found on the non-stick surface after testing.”

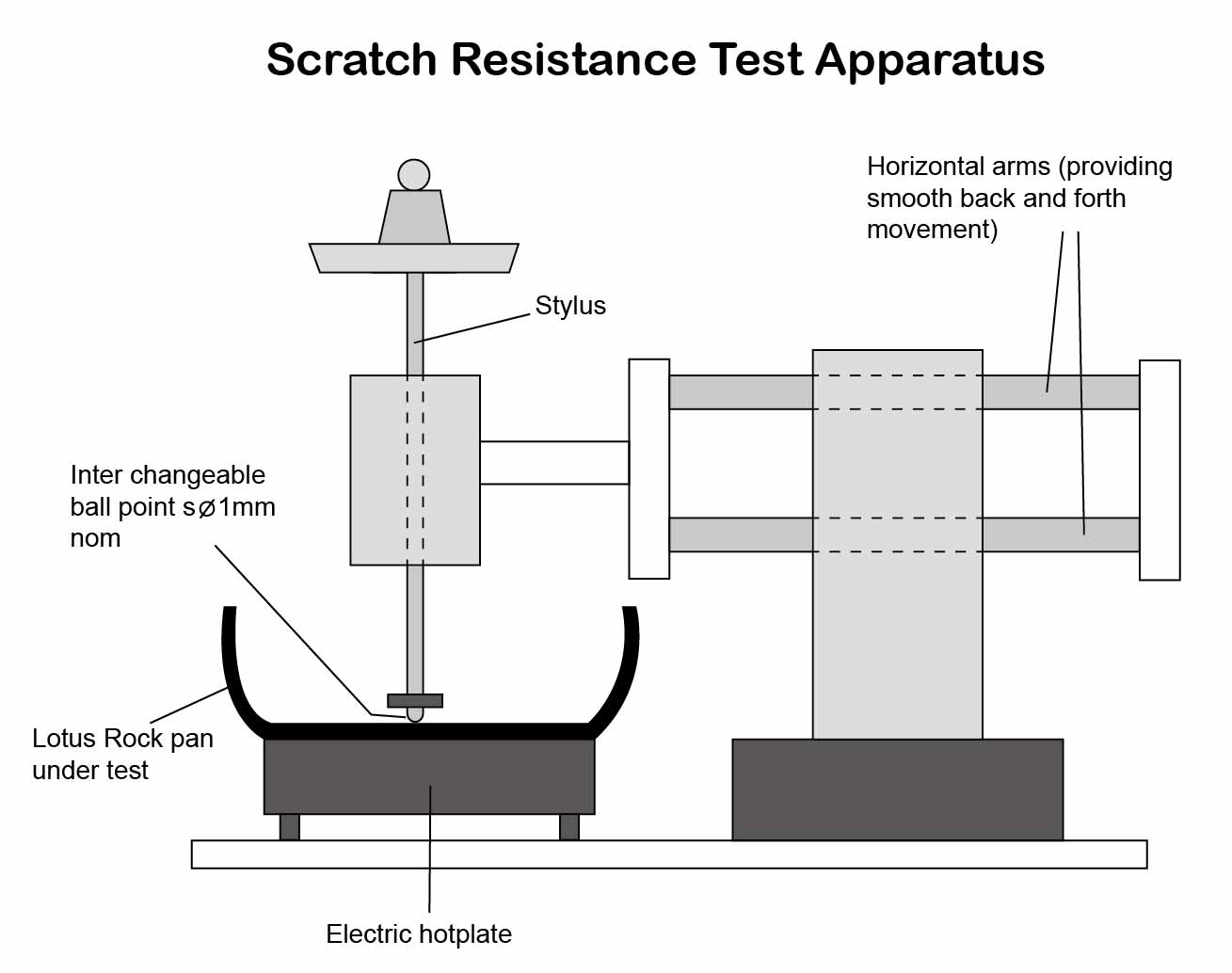

2. BS 7069 Scratch Resistance Test Procedure

Place a quantity of corn oil, sufficient to just cover the base of the article into it. Heat the vessel to a temperature of 220+5C and apply the loaded stylus to the heated surface. Move the loaded stylus across the surface for a distance of not less than 80mm in 1+0.1s.

SGS test result for Lotus Rock pan = Pass. “No visible damage was found on the non-stick surface after testing.”

One of the significant benefits of a Lotus Rock pan is the high durability of the pan’s surface. Unlike general non-stick PTFE-coated pans, Lotus Rock is metal utensil safe, which means a stainless steel spatula or knife and fork can be used on the surface without any concern that the quality of the coating will be impaired or the non-stick release ruined through scratching. Moreover, for cleaning purposes a Lotus Rock pan can, unlike with a general PTFE non-stick coated pan, be scrubbed and washed vigorously with a standard abrasive cleaning pad without causing the coating to peel off.

May 11, 2025 / arnoldtnn / 0 Comments

The introduction of a new, highly innovative product into the market often generates considerable excitement and interest. However, at the same time, there is naturally also some concern as to whether this new product is safe to use and not hazardous to human health.  A famous example of this was when PTFE-coated cookware was first introduced in the 1960’s. This new, technological breakthrough in non-stick coating for cookware was a huge hit among consumers who wanted an easier, and more hassle-free way to cook daily staples, such as eggs. But in the late 90’s it was found that the emulsifier used to spread the PTFE coating evenly around the pan, called PFOA, caused birth defects in laboratory animals. This substance was subsequently banned by the Food & Drug Administration (FDA) of USA, and by government departments in many other countries.

A famous example of this was when PTFE-coated cookware was first introduced in the 1960’s. This new, technological breakthrough in non-stick coating for cookware was a huge hit among consumers who wanted an easier, and more hassle-free way to cook daily staples, such as eggs. But in the late 90’s it was found that the emulsifier used to spread the PTFE coating evenly around the pan, called PFOA, caused birth defects in laboratory animals. This substance was subsequently banned by the Food & Drug Administration (FDA) of USA, and by government departments in many other countries.

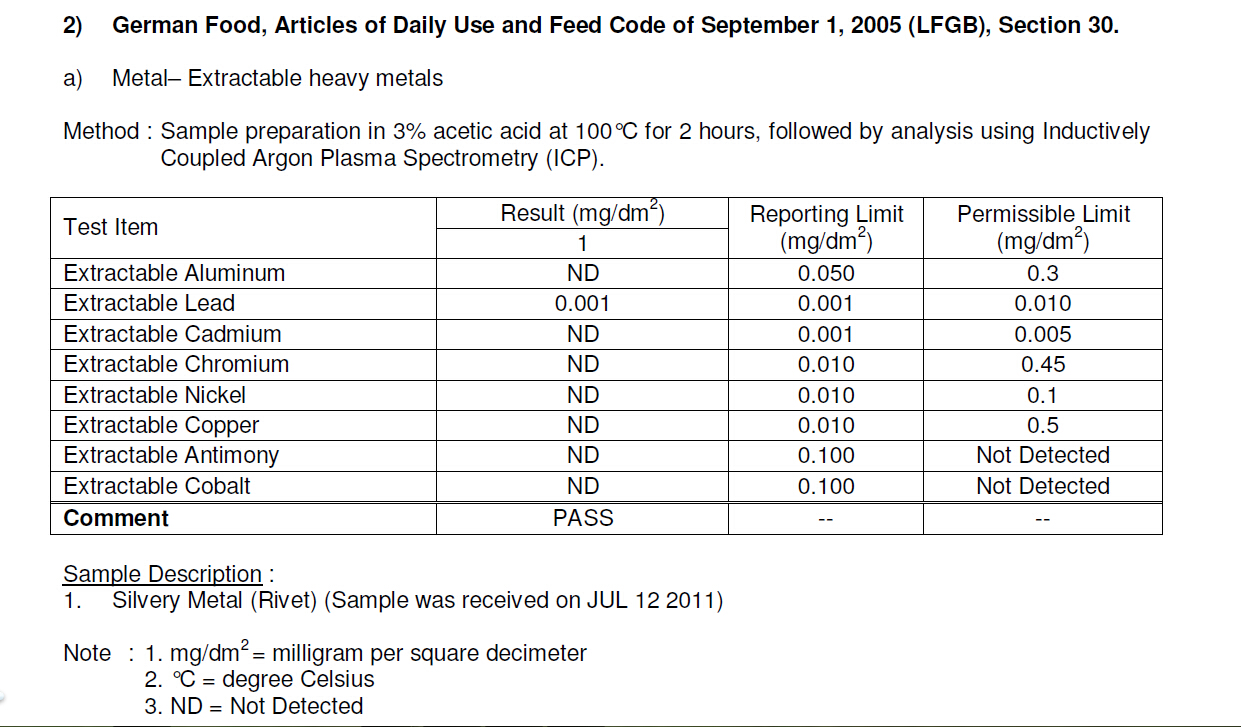

Since its creation a number of years ago, Lotus Rock cookware and bakeware has been sold throughout the world, in countries such as USA, Australia, Israel, Turkey, South Africa and India. Part of the reason why so many retailers and wholesalers in these countries have enthusiastically sold and recommended Lotus Rock has been the numerous testing reports, produced by reputable companies such as SGS and TUV, which have demonstrated Lotus Rock’s safety for use in the kitchen.

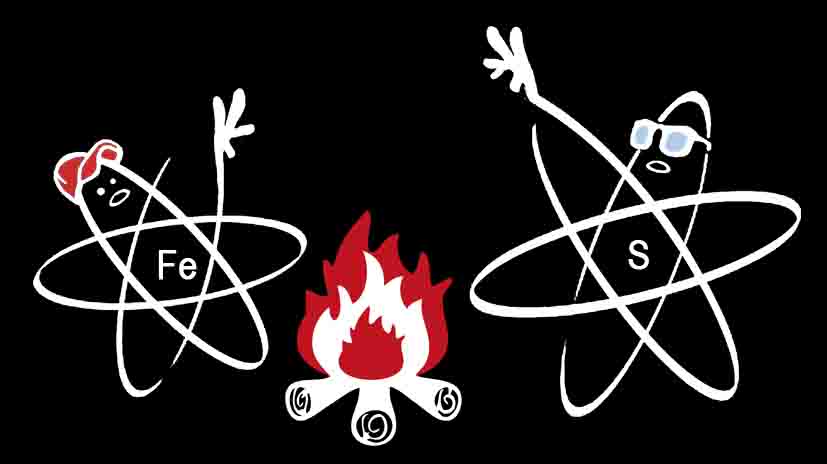

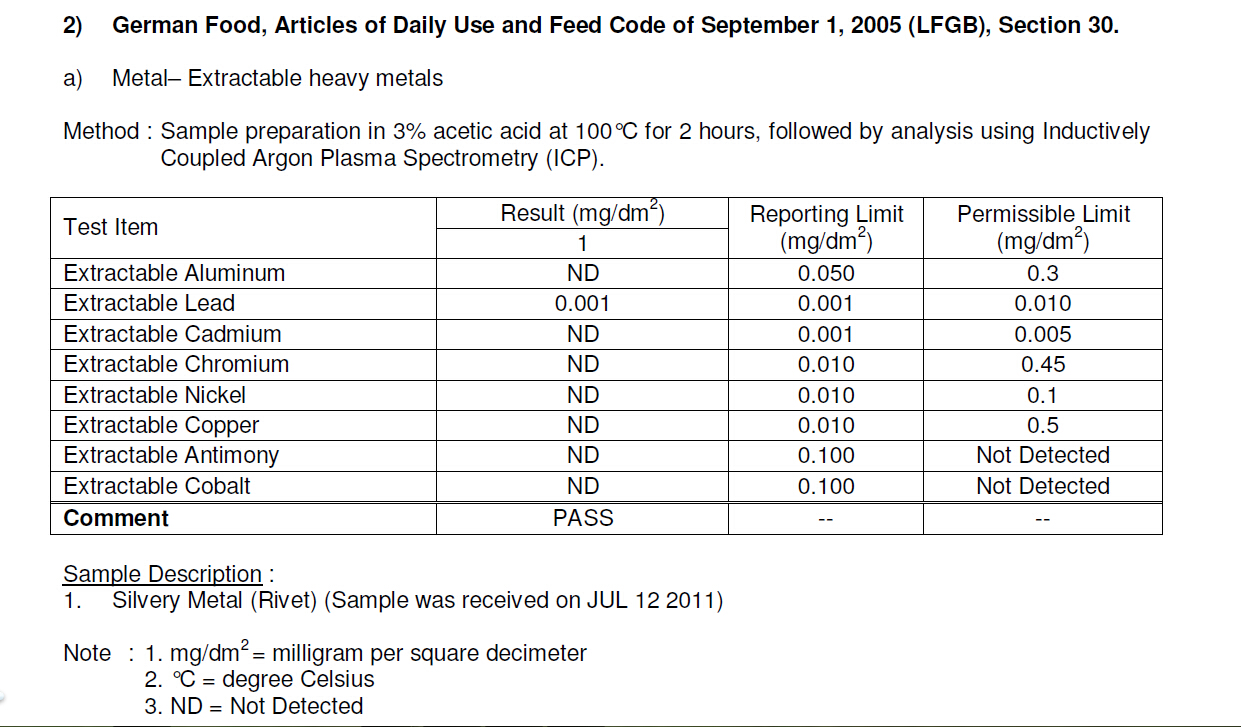

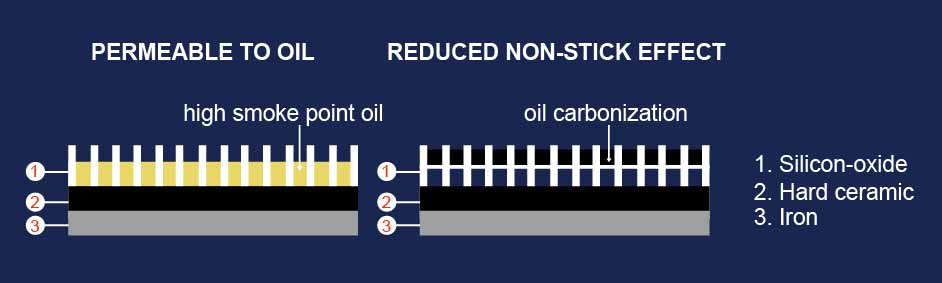

The kitchenware industry commonly uses a migration test to assess the reactivity of a product’s surface. Cookware materials that are highly reactive are those which tend to have chemical reactions with other substances around them. Highly reactive materials include iron, copper, aluminum and carbon steel. Highly reactive cooking surfaces are disadvantageous for certain ingredients and ways of cooking because the reactions can produce undesirable colors and/or flavors. No Lotus Rock pans are highly reactive with any ingredients because they have a thick non-reactive ceramic layer on both the interior and exterior of the 2.0mm carbon steel substrate. Further, the interior of all Lotus Rock pans has an additional top coating of silicon-oxide crystal, which is permeable to cooking oil but impervious to other substances. Thus, highly reactive ingredients such as tomatoes, spinach, wine and lemon juice can be used on Lotus Rock pans without creating any chemical reactions.

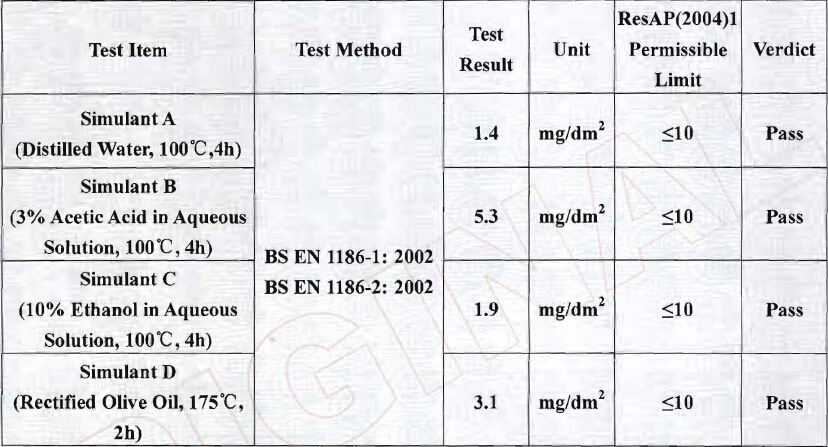

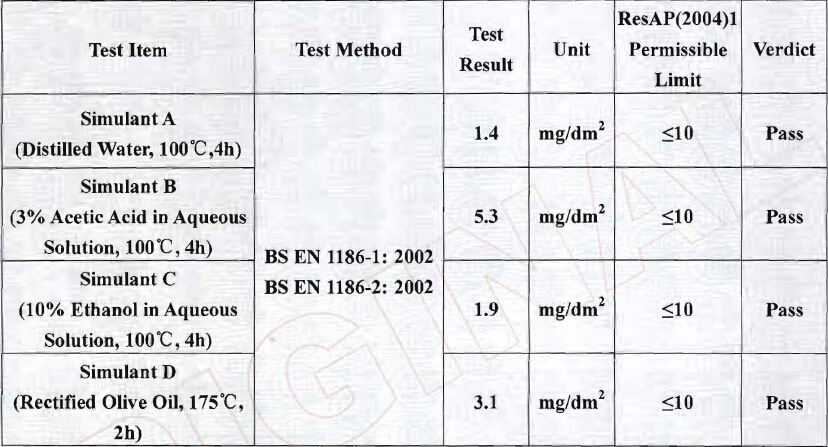

The most commonly used migration test to demonstrate whether or not the surface of a cookware utensil is reactive to different ingredients, set up in accordance with British and European standards, is BS EN 1186-1.2 2002. This test involves heating four different simulants on a cookware item, at different temperatures and for different periods of time, before determining whether any part of the surface of the cookware has reacted with the simulant. These four simulants are:

- Distilled Water, to simulant boiling or simmering;

- 3% Acetic Acid in an aqueous solution, to simulate the use of citric juices such as lemon for flavor, or tomatoes for a sauce (such as Bolognese);

- 10% ethanol in aqueous solution, to simulate for example the use of alcohol for deglazing a pan to made a sauce;

- Rectified olive oil, for general high heat cooking methods, such as frying, sautéing, stir frying, browning and grilling.

The table below is the result of just such a BS EN 1186-1.2 2002 test, one which was performed on a Lotus Rock frying pan, grill pan and saucepan.

The testing standard for each simulant is expressed in milligrams of extracted of deposited material per decimeter squared. As is clearly demonstrated above, each simulant recorded an extracted quantity well below the permissible limit of 10 milligrams per decimeter squared.

The above BS EN 1186-1: 2002 migration test clearly proves that a Lotus Rock pan can be used for a variety of cooking methods, such as boiling, frying and deglazing, and can be cooked with a variety of different ingredients, without any concern that the an unwanted reaction might take place with the pan’s surface.

May 9, 2025 / arnoldtnn / 0 Comments

So far on this blog we have explained the various tests that are conducted to ensure that a Lotus Rock pan is safe and fit for purpose in a variety of domestic kitchens all over the world. Some of these tests are for the coating surface, some are for handles, and some are to check that the material composition of the pans contain no harmful substances or metals.

However, in spite of all these tests there might still be some issues with a product which all of these tests cannot safeguard against. In fact, some problems can only be experienced and then later resolved once the product has actually been used by the consumer.

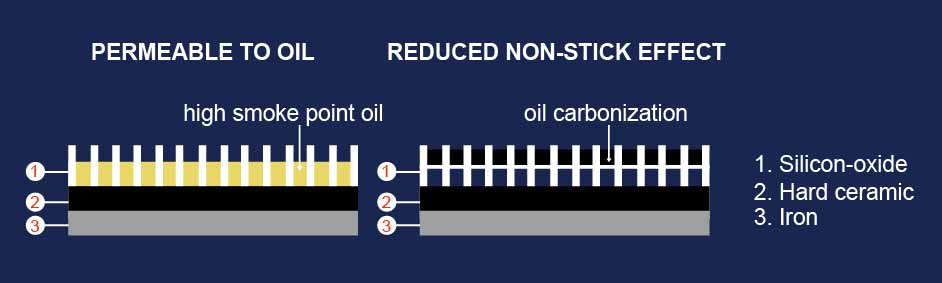

One such issue, which some consumers of a Lotus Rock pan have mentioned, is staining on the coating surface. The reason this problem occurs on a Lotus Rock pan more often than, say, on either a non-stick or stainless steel pan, is that the coating surface of Lotus Rock is rougher and more uneven. As explained previously, these ‘valleys’ on a Lotus Rock pan surface are actually there for a very specific reason: to create a natural, durable non-stick surface. The silicon-oxide crystal coating is permeable to oil and rests in between these ‘valleys’. So the consumer can maintain the non-stick release of the pan regularly by wiping a small amount of oil on a Lotus Rock pan, just like they would do if they added oil to an uncoated steel or cast iron pan to season it.

However, when consumers cook with a Lotus Rock pan occasionally other ingredients might intrude into these ‘valleys’. Or alternatively the consumer might use too much oil on the pan and the surface might then become too sticky.

One particular advantage of a Lotus Rock pan which many consumers don’t fully appreciate is that it does have excellent abrasion and scratch resistance. Since the 1960’s when PTFE non-stick pans were first introduced, consumers have become accustomed to being careful about how they use and clean their non-stick pan for fear of damaging the non-stick surface. They will, for example, always use the yellow sponge side of a cleaning pad, and not the more abrasive green side.

As explained, one of the significant advantages of a Lotus Rock pan is that it can be scrubbed and cleaned in a much more thorough and robust way than a general non-stick pan. Below is an example of a Lotus Rock which has some staining on the coating surface.

Generally, a consumer has two cleaning methods to clean this pan:

1. Boil vinegar in the pan

2. Scrub the pan surface with washing-up detergent and hot water

If either of the above two methods were used to clean a general non-stick coated pan then the pan could be made obsolete for further use: the coating could either peel off or crack.

As you can see from the photo above, both methods cleaned this 34cm Lotus Rock paella pan with similar success. Although boiling vinegar over the pan did remove the staining, we would in most cases recommend just cleaning the pan with hot, soapy water and a general abrasive pad. If this does not remove all the staining, then the other option of boiling vinegar can be used.

May 4, 2025 / arnoldtnn / 0 Comments

If there is one word that has been over-used for marketing purposes in the last decade it is “green”. Within society increasing concerns about climate change, and whether economic growth is compatible with environmental protection, has led companies all over the world to market their products as eco-friendly and “green”. However, it has now reached the point where the inclusion of any recycled or natural resource in a product, no matter how small a part it forms of the whole, is used to justify the label “green”. This term for eco-friendly products has been used so frequently over the years that its meaning to most consumers has become quite vague and ambiguous. One way to consider whether a product is eco-green would not be so much its composition, but instead how durable it is. An item which needs to be replaced every year consumes five times as many resources as an item which lasts for five years. It is for this reason, its durability, that a cooking utensil such as a frying pan can be labelled and marketed as ‘eco-green’. All Lotus Rock pans are suitable for long-term use and for this reason are labelled as ‘eco-green’. Lotus Rock is highly durable for a number of reasons:

- Strong construction. With a heavy-gauge carbon steel substrate and a thick layer of enamel on both the interior and exterior of all pans, Lotus Rock pans will not warp or disfigure easily. Carbon steel is a very dense material, and the 2.0mm gauge used in all Lotus Rock pans makes them strong and long-lasting, unlike pans made with aluminum, a material with a very low density, which can be dented and disfigured quite easily, for example, if accidently dropped on the kitchen floor.

- Abrasion resistance. A common complaint about non-stick pans is that the coating often peels off quite easily, making the pan unusable and requiring its replacement. A Lotus Rock pan, in contrast, is metal utensil-safe. The coating is extremely hard and can withstand scrubbing with a 3M pad for a long period of time.

- Natural non-stick release. A non-stick coating with either PTFE or ceramic sol-gel technology will, depending on its quality, eventually become a ‘stick’ pan. Once the non-stick release has worn out the pan will become difficult to clean, and the consumer will most likely discard it. In contrast the natural non-stick coating on a Lotus Rock can be renewed by simply wiping oil onto the surface before each use. This method gives the pan a much longer lifetime than a general non-stick pan.

If the Stable Concave design is included a Lotus Rock pan’s lifetime is extended even further In addition to its durablity, a Lotus Rock pan can also because of its fast heating effect be labelled eco-green. Many professional chefs prefer carbon steel for cooking utensils such as stir woks, crepe pans, paella pans and frying pans because it heats up very quickly. This is especially so compared to other commonly used metal substrates such as aluminum or stainless steel. If the steel for a pan is produced at a thick gauge then it can heat up quickly, but also evenly across the pan’s surface. The main environmental benefit of a faster heating effect is that it saves energy from the stove top burner, thus reducing CO2 emissions. .

April 29, 2025 / arnoldtnn / 0 Comments

As many consumers have written in their reviews here, Lotus Rock has a number of significant benefits for cooking in a domestic kitchen. Some of these consumers mention about Lotus Rock’s excellent heating effect for pan frying, such as for chops, steak and frittatas; some like the weight of the pans – that they are heavy but not nearly as much as a cast iron pan; others love that they can use metal utensils without chipping off the surface; and some really appreciate that all Lotus Rock pans are induction safe. These are to name but a few of the benefits that come with using a Lotus Rock cookware utensil.

However, it is highly probable that a number of these consumers enjoyed using their Lotus Rock pan because they had in fact done what many of us just don’t want to do and……..read the instructions first before use.

On all Lotus Rock packaging sold around the world, the wording may vary slightly, but there are 5 basic use and care instructions, there are:

1. Hand wash in hot soapy water with a scouring pad. Put the pan on a medium heat setting and wait for all the moisture to evaporate. Once the pan is completely dry apply oil around the interior surface.

For more information about this procedure please read here.

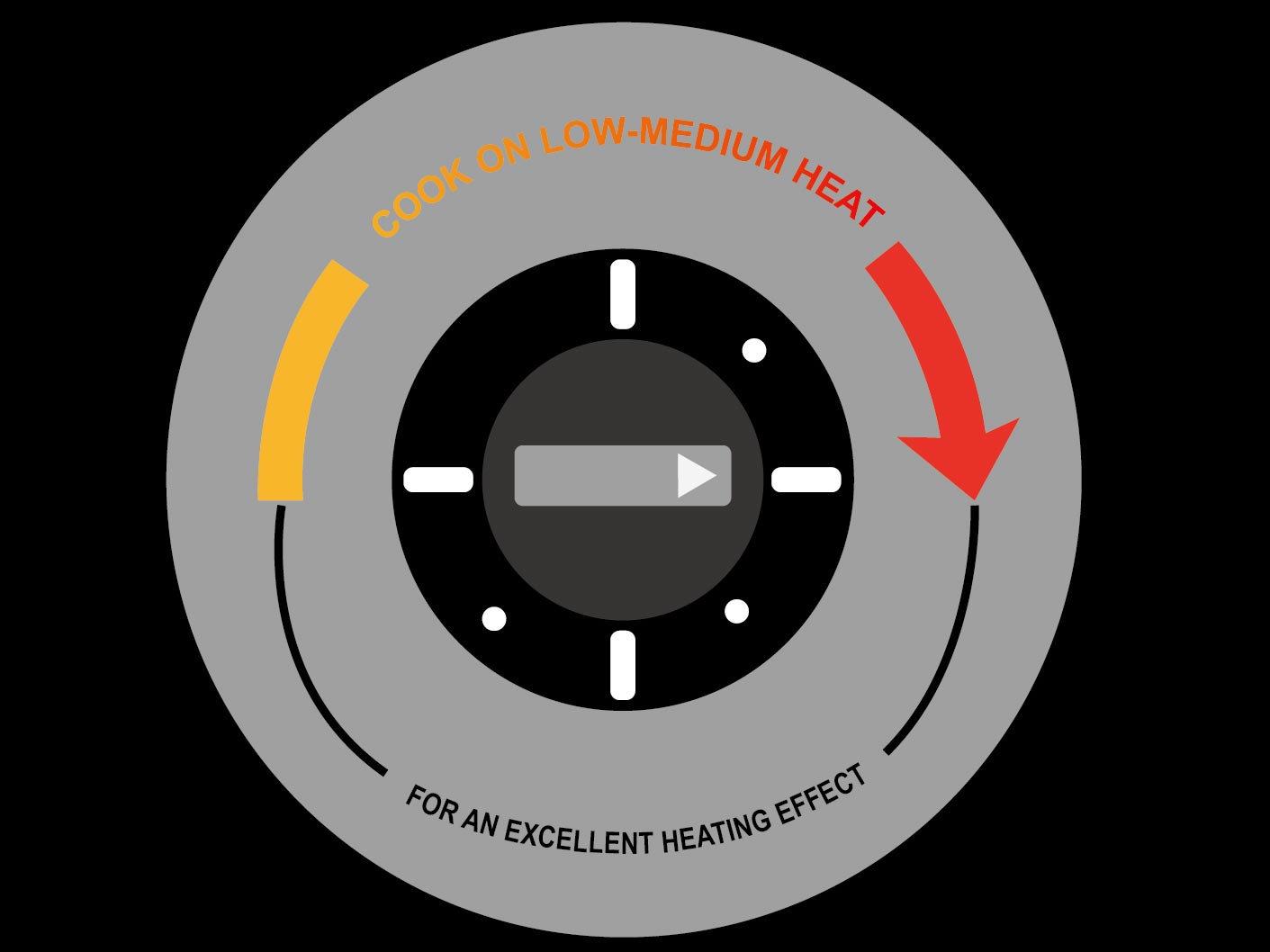

2. Transfers heat very fast. Pre-heat the pan on a medium-low setting, a little later add oil to the pan, and when it appears to be hot enough add the ingredients for cooking.

For more information about this please read here.

3. Never leave your pan unattended while cooking.

As the 2nd instruction states, a Lotus Rock pan heats up very quickly, much faster than most other standard materials used for cookware, so a pan should always be supervised while it is being heated on the stove. Quite often if this is not done then a white mark will appear on the pan. A Lotus Rock pan can still be used after this has happened, however some of the non-stick function from the silicone-oxide crystal coating would have been impaired beyond repair.

4. Always keep your pan dry when not in use.

Primarily because of its extremely thick and strongly bonded coating, a Lotus Rock pan does have much better corrosion resistance than other coated carbon steel pans sold in the market today. However, if a Lotus Rock pan is stored in a very moist condition, or if it is left to soak in a sink for an extended period of time, then the likelihood of rust developing is much more likely.

5. Hand wash recommended.

In fact, a Lotus Rock can technically be used in a dishwasher, but it is not recommend for two reasons. Firstly, as pointed out in the 4th instruction, although a Lotus Rock pan does have a very thick coating, the intensity and duration of a wash in a dishwasher will increase the likelihood of rust (especially along the edges of a pan). Second, dishwasher use may gradually impair the quality of the silicon-oxide crystal coating, which is an essential component for the non-stick release of a Lotus Rock pan.

There is another very useful use and care instruction for a Lotus Rock pan which is not often included on the packaging because of its complexity and the lack of space available: this is to re-new the non-stick effect of the pan. For information about this please read here.

April 20, 2025 / arnoldtnn / 0 Comments

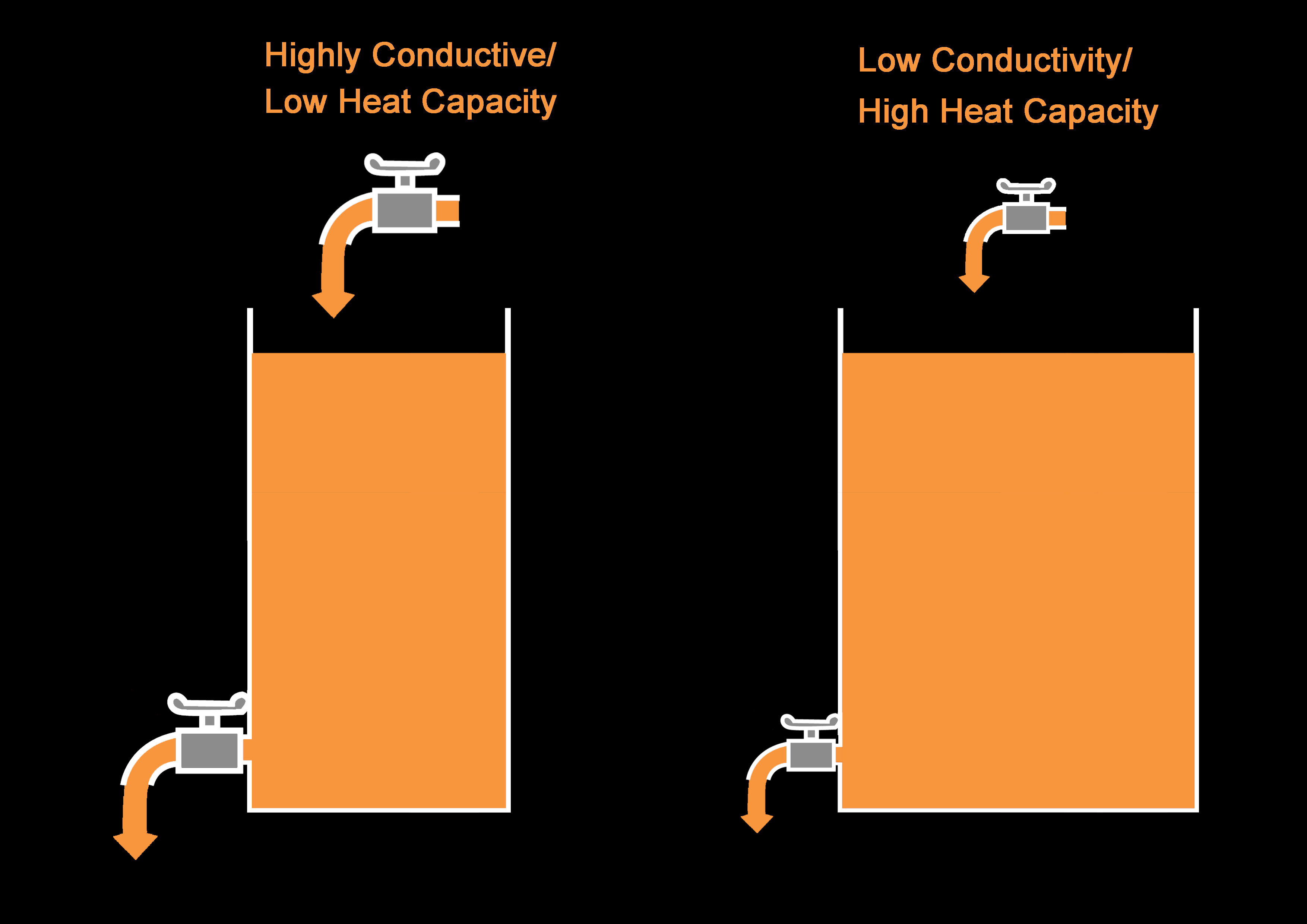

As noted previously here, all Lotus Rock pans have an excellent high heating effect, a desirable quality which helps produce delicious tasty food. What thermal properties give a cooking utensil an excellent heating effect? Well, first, the pan must heat up quickly when placed on the heat sources; second, it has to be thick enough to heat up evenly across its surface; and third, it needs a large enough thermal capacity to minimise loss of heat when food is added to the pan.

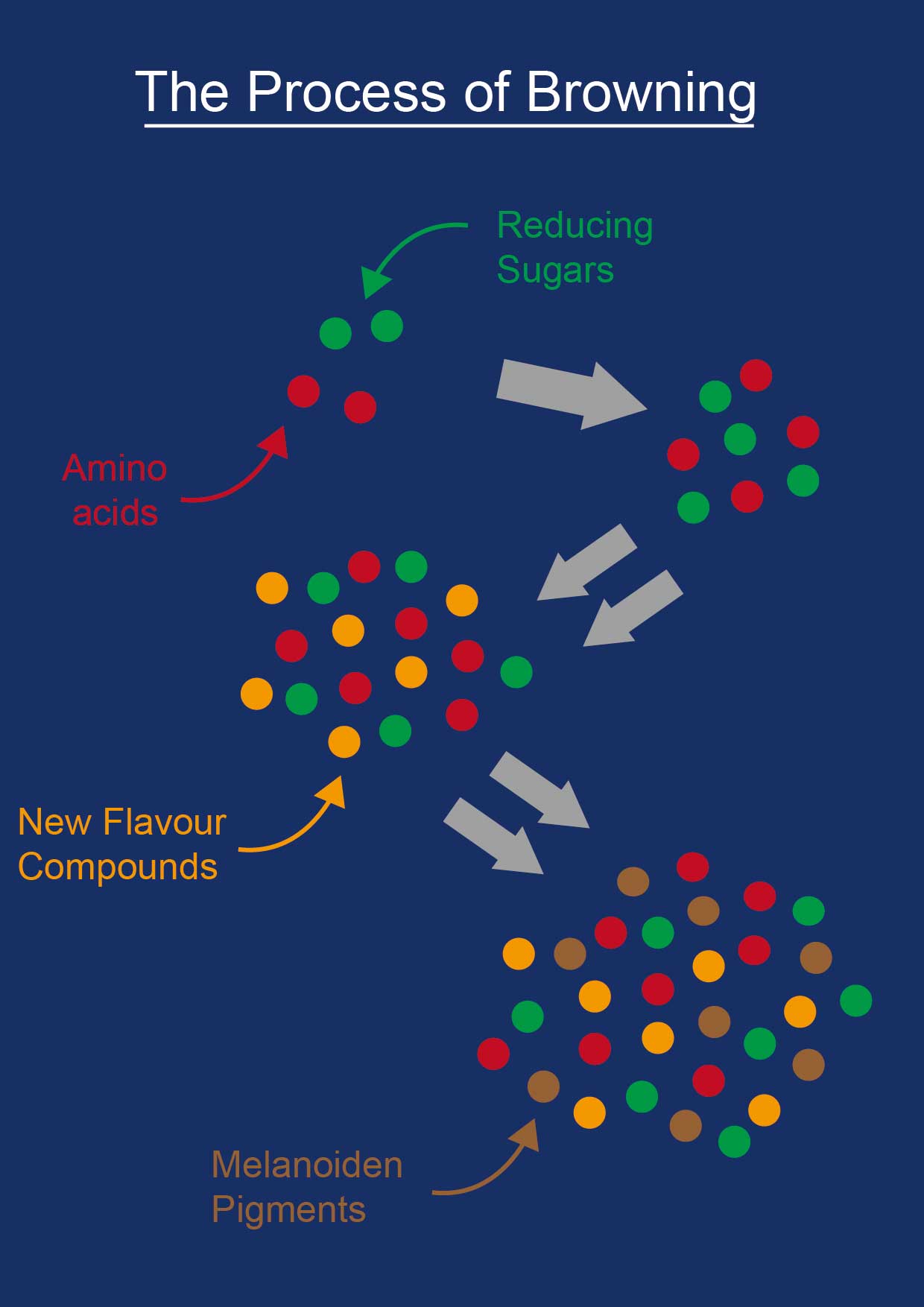

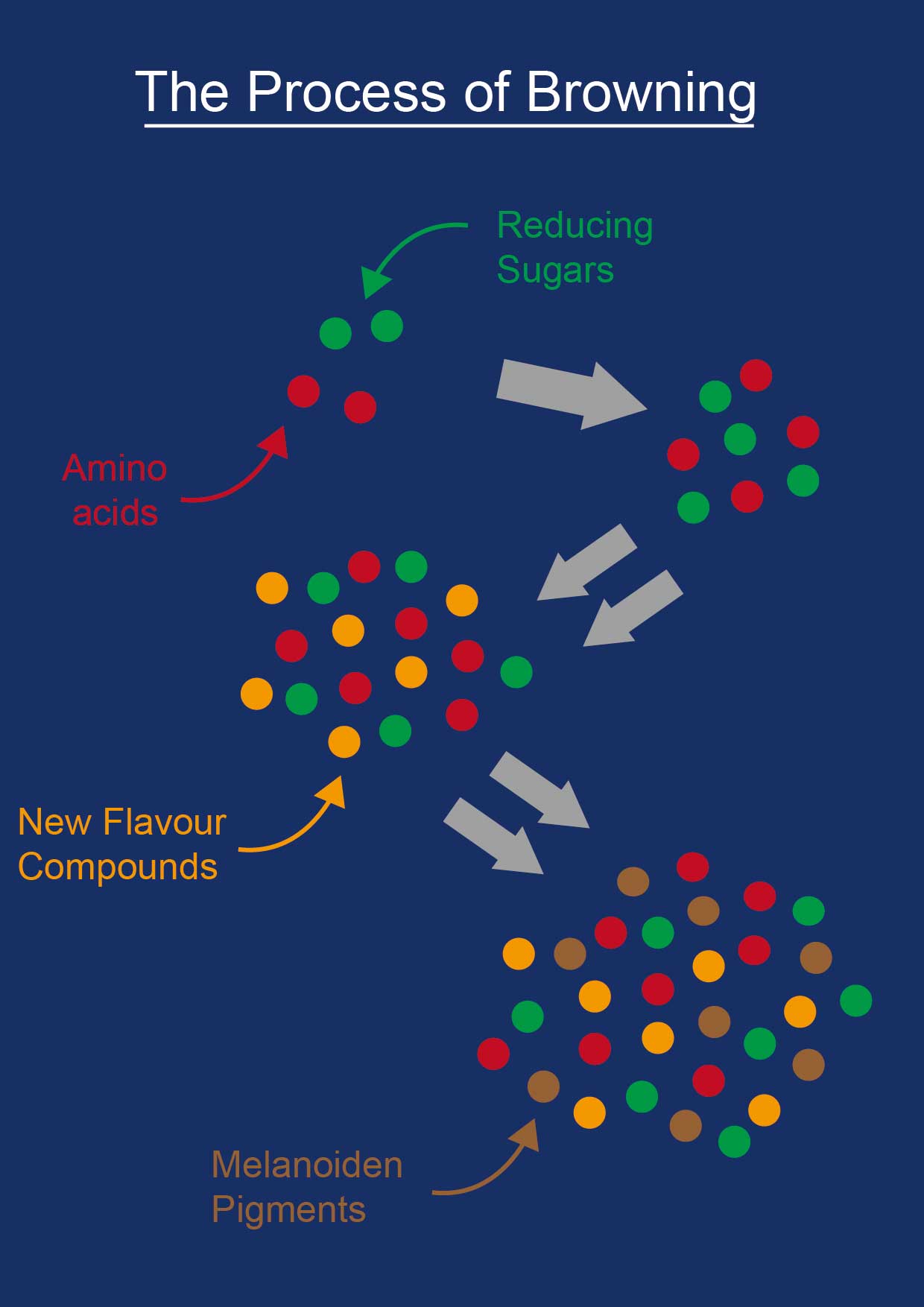

Let’s start with the Lotus Rock pan’s prompt response to heat. Although carbon steel does not heat as evenly as aluminum, it does heat up much more quickly. Some methods of cooking require the pan to have reached a certain temperature before it is used; for example, browning, which is best done on a pan with a temperature of 180 degrees (this is the temperature when the Maillard Reaction begins to take effect). If an impatient cook starts before the pan reaches this temperature then the meat or vegetables being seared might still be browned but will have lost a large amount of moisture, making it dry and un-appetizing.

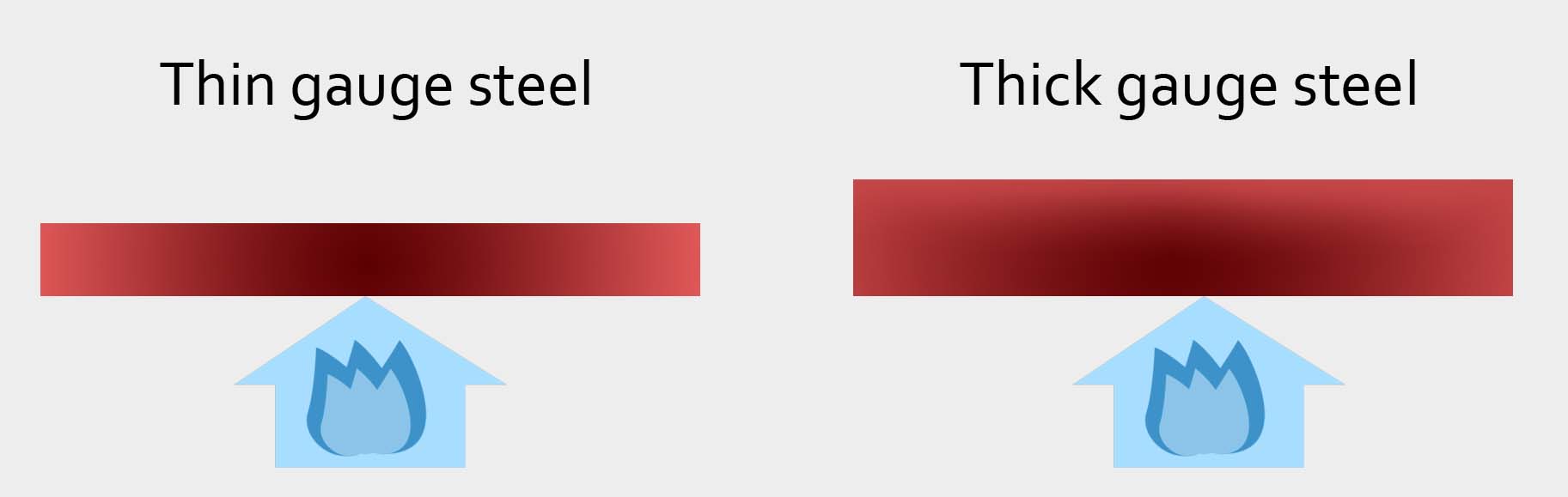

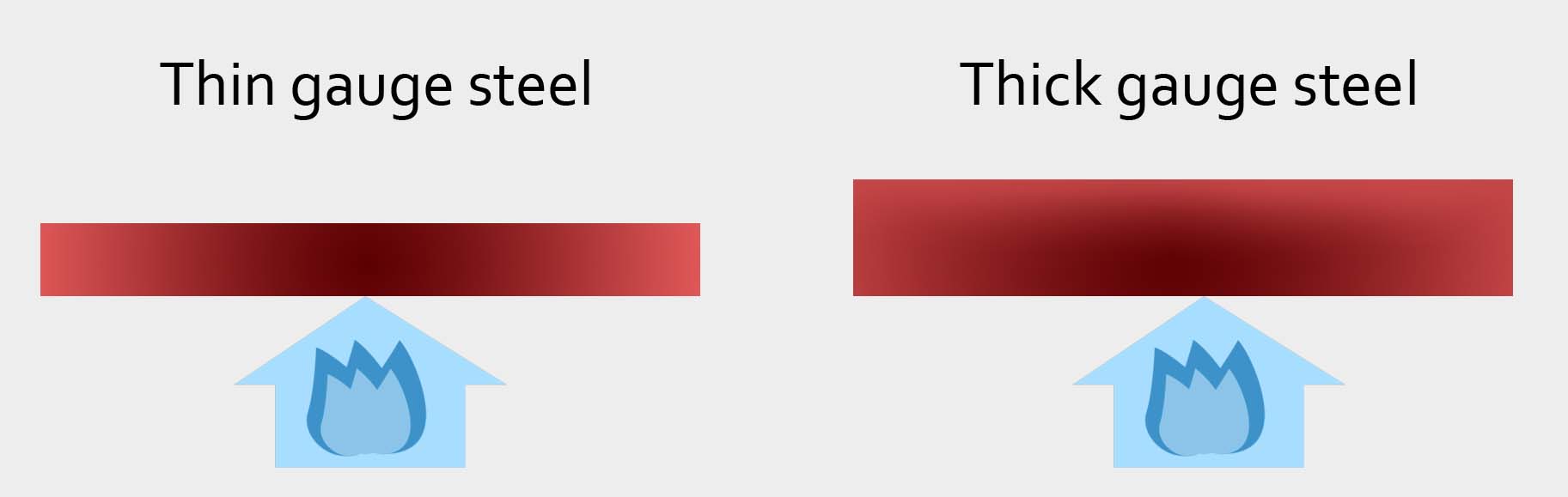

However, although carbon steel heats up quickly, a thin gauge of steel will do so unevenly, heating up most quickly in the centre of the pan. This not only creates a hot spot, causing uneven cooking, but will eventually warp the pan and give it a convex shape, causing oil and other liquids to slide to the edges. In order to disperse the heat more evenly around the pan all Lotus Rock pans are made with 2.0mm gauge steel. As is shown in the diagram below, a thicker gauge broadens the area at which the heat reaches the surface of the pan.  So with carbon steel as its substrate Lotus Rock pans can not only heat up very quickly but can also, due to the steel’s thick 2.0 gauge, provide a more dispersed heating effect so that the food is cooked evenly. It thus meets the first and second criteria for an excellent high heating effect. What about the third criterion? What happens to the heating effect of a Lotus Rock pan when food is added?

So with carbon steel as its substrate Lotus Rock pans can not only heat up very quickly but can also, due to the steel’s thick 2.0 gauge, provide a more dispersed heating effect so that the food is cooked evenly. It thus meets the first and second criteria for an excellent high heating effect. What about the third criterion? What happens to the heating effect of a Lotus Rock pan when food is added?

If you were to compare all the main metals for cookware usage, you would find that carbon steel is among the most dense (three times more dense than aluminum, for example), and as we know, Lotus Rock has a very heavy carbon steel gauge. This extra mass and space in its substrate means a Lotus Rock pan has a high heat storage capability, an essential component for an excellent heating effect. When a steak is placed on a grill pan to impart that smoky, chargrilled aroma, or a large quantity of vegetables are quickly added to a stir wok, the high thickness and density of a Lotus Rock pan will minimiss heat loss. So instead of steaming in their own juices, the steak and vegetables will sizzle and heat up quickly and evenly for a delicious and crispy taste.

A second factor facillitating heat retention is the thick layer of ceramic on both the interior and exterior of all Lotus Rock pans. Most coatings on cookware sold throughout the world today have a thickness between 15-30 microns; the ceramic layer on Lotus Rock pans is in contrast around 100 microns thick. This thick coating increases the heat retention capability of all Lotus Rock pans due both to its extra mass and poor heat conductivity. Ceramic does not conduct heat very well, but it is good at storing heat – this is why it is often used for oven dishes.  So when food is added to an already well heated Lotus Rock pan the temperature should not drop significantly, in part because of the heavy gauge carbon steel substrate but also because of the thick ceramic layer on both the interior and exterior of the pans. Thus the very thick material of a Lotus Rock pan is perfect for high heat cooking methods, such as for sautéing, searing, grilling and stir frying.

So when food is added to an already well heated Lotus Rock pan the temperature should not drop significantly, in part because of the heavy gauge carbon steel substrate but also because of the thick ceramic layer on both the interior and exterior of the pans. Thus the very thick material of a Lotus Rock pan is perfect for high heat cooking methods, such as for sautéing, searing, grilling and stir frying.

April 11, 2025 / arnoldtnn / 0 Comments

Crepes are a famous French delicatessen which is extremely versatile, perfect for brunch, lunch, a light supper — and definitely dessert. Crepes are served with a variety of fillings, from the most simple with only sugar to flambéed crepes Suzette or elaborate

savoury galettes.

A Lotus Rock pan is perfect for cooking crepes for the following reasons:

Fast heating effect. For a delicious, tasty crepe the whole cooking process should not take any longer than 80 seconds; 60 seconds at first, and then 20 seconds after the crepe has been flipped over. In order for this to happen most effectively the crepe needs to be on a pan that heats up quickly – carbon steel, the substrate for all Lotus Rock pans, is ideal for this. None of the other commonly used substrates, such as aluminum*, stainless steel, cast iron and copper, heats up as quickly as carbon steel.

*A big disadvantage about aluminum is that even though it does spread heat evenly around a pan extremely well (only copper is better at doing this), it heats up much slower than carbon steel. This means the crepe will not be as crispy and tasty as it could be if it is cooked on a Lotus Rock pan. In fact, a crepe cooked on an aluminum pan could easily be overcooked or become rubbery.

Heat dispersion. Although carbon steel does heat up quickly, it does so in the centre of the pan. If the gauge of the carbon steel crepe pan is too thin then the outer edges of the crepe pan will cook much slowly than the centre, meaning either the centre is burned or the edge of the crepe is undercooked. Because Lotus Rock has a thick 2.0mm carbon steel gauge and a thick coating on top of that, the pan heats up quickly but also evenly. This creates the perfect heating effect for a delicious, appetizing crepe.

Heat retention. Although crepes, because of their thin nature, should not have too much of a thermal load, and thus not reduce the temperature of the pan much, a good crepe pan should still retain as much heat* as possible while cooking. If it does then by the 2nd or 3rd crepe the pan should reach a suitable and stable temperature to transmit heat effectively to the batter to create a better tasting crepe.

*The only other metal substrate which retains heat better than carbon steel is cast iron. However, cast iron is extremely heavy, so some people will find flipping more than a few crepes a bit troublesome.

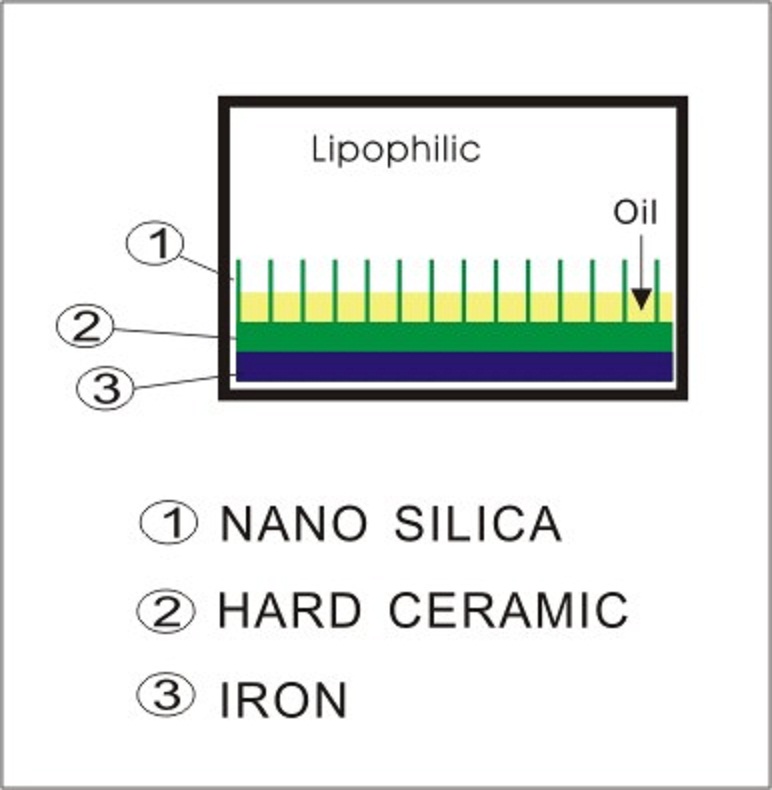

Easy clean-up. A lot of crepe pans in the market today are produced with carbon steel or cast iron but are uncoated. This means that the customer has continually to re-season the pan which some cooks find time-consuming and complicated. Moreover, consumers cannot use washing-up detergent or scrub too hard on the pan’s surface, because that might remove the natural non-stick patina that forms on crepe pans after some use. On the other hand Lotus Rock hydrophobic nano-silica coating is extremely easy-to-clean, with any type of washing-up liquid or abrasive pad.

Other benefits of a Lotus Rock crepe pan include:

- Induction safe. This type of cooking top surface is particularly suitable for cooking crepes, which need to be cooked quickly, because induction stove tops transmit heat much faster than either gas or electric.

- Metal utensil safe. A metal spatula can be used for flipping the crepe without damaging the coating.

- Low sides. This is especially useful for easy removal of crepes.

- Other uses. Lotus Rock crepe pan is also ideal for heating up tortillas, acting as a griddle for pancakes, and for making other delicious items such as Indian flatbread and Omelets.

A Lotus Rock crepe pan is sold in a 24cm, 26cm, 28cm and 30cm sizing. With the hollow cast stainless steel handle above the pan is oven safe to 650 degrees Fahrenheit and it is broiler safe. It is suitable for all cooktops, including electric, gas, halogen, ceramic, glass and induction. After limited use a Lotus Rock crepe pan can be used in a dishwasher, but a regular hand wash is recommended.

April 1, 2025 / arnoldtnn / 0 Comments

The metal substrate for all Lotus Rock pans is heavy gauge carbon steel. There are numerous reasons why Lotus Rock uses this substrate instead of more commonly used metals for cookware, such as aluminum or stainless steel, as explained here. Traditionally for cookware usage carbon steel is often sold as uncoated, with just a protective coating on it which needs to be removed prior to use. Generally, the instructions on the packaging for uncoated carbon steel cookware items such as stir woks, frying pans and paella pans advise the consumer to season the pan before use.

What exactly is seasoning?

According to Wikipedia, seasoning is “the process of treating the surface of a saucepan, wok, crepe griddle or other cooking vessel with a stick-resistant coating formed from polymerized fat and oil on the surface.” It goes on to say that it is desirable for carbon steel cookware “because otherwise they are very sticky to foods and rust-prone. It is generally not desired on other types of cookware either for cosmetic reasons or because the chemical composition of the pan already results in a non-stick surface.”

So, basically uncoated carbon steel cookware needs a polymerized oil film over it for two reasons:

- Corrosion resistance

- Non-stick release.

Regarding the first reason to season a carbon steel pan – corrosion resistance – this is not necessary for Lotus Rock. This is because on both the interior and exterior of all Lotus Rock pans there is a thick enamel coating. So, as long as the Use & Care instructions are followed properly a Lotus Rock pan will not rust because the coating prevents the surface of the steel from any form of oxidation.

Is seasoning needed for non-stick release?

For the second reason to season a carbon steel pan – the non-stick release – this is also not necessary because all Lotus Rock pans have a silicon-oxide crystal coating. As explained here, this lipophilic coating gives all Lotus Rock pans a natural, durable non-stick release. While most non-stick pans on the market today have PTFE included in their coating to give them a non-stick effect, all Lotus Rock pans in contrast are PTFE/ PFOA free. The non-stick release for Lotus Rock comes from the consumer adding oil themselves to the pan prior to cooking and letting it permeate the silicon-oxide crystal coating.

However, although both seasoning and the process explained above do involve heating oil on an iron pan, the latter cannot be termed as seasoning for two reasons. First, seasoning is a reaction between the oil and the steel surface. With all Lotus Rock pans, cooking oil is never in contact with the heavy gauge steel substrate; instead the added cooking oil rests within the silicon-oxide crystal coating and on top of the thick ceramic coating.

The second reason is that for a carbon steel pan to be properly seasoned the oil needs to react with the steel surface and be polymerized. For seasoning to be successful the oil needs to surpass its smoke point, and then the chemical composition of the oil will alter to form a solid, hard film over the steel. For a Lotus Rock pan to have an effective and potent non-stick release or for that matter any other non-stick pan to be maintained well, the cooking oil should never be allowed to polymerize. If done so, it will form a barrier between the food and silicon-oxide crystal coating, which will impair the non-stick quality of the pan.

Disadvantages of a seasoned pan

Although a seasoned steel pan undoubtedly has many benefits, to continually re-season a pan can be for some quite a hassle. Moreover, a seasoned pan does have some limitations when it comes to cooking. For example, ingredients which have are highly acidic cannot be used, such as lemon juice or tomatoes, because they will remove the non-stick patina which with continued use of fat for cooking occurs naturally on the pan. Another difficulty with a seasoned pan is that it is not suitable for de-glazing. Once the fond has built up on the pan after searing meat, generally an acidic liquid such as wine or broth is added to create a sauce. However, as has already been explained, the acidic nature of these sauces will react with the steel surface and impair the non-stick quality of the pan.

Although a seasoned steel pan undoubtedly has many benefits, to continually re-season a pan can be for some quite a hassle. Moreover, a seasoned pan does have some limitations when it comes to cooking. For example, ingredients which have are highly acidic cannot be used, such as lemon juice or tomatoes, because they will remove the non-stick patina which with continued use of fat for cooking occurs naturally on the pan. Another difficulty with a seasoned pan is that it is not suitable for de-glazing. Once the fond has built up on the pan after searing meat, generally an acidic liquid such as wine or broth is added to create a sauce. However, as has already been explained, the acidic nature of these sauces will react with the steel surface and impair the non-stick quality of the pan.

The silicon-oxide crystal coating of a Lotus Rock pan on the other hand is much less troublesome for cooking with. All kinds of acidic ingredients can be used with a Lotus Rock pan. So, for instance, a spaghetti Bolognese can be cooked on a Lotus Rock pan without any detriment to the quality of the non-stick release. In addition, a sauce such as gravy can be prepared from the fond after some chicken breasts have been seared on the stove top.

The silicon-oxide crystal coating of a Lotus Rock pan on the other hand is much less troublesome for cooking with. All kinds of acidic ingredients can be used with a Lotus Rock pan. So, for instance, a spaghetti Bolognese can be cooked on a Lotus Rock pan without any detriment to the quality of the non-stick release. In addition, a sauce such as gravy can be prepared from the fond after some chicken breasts have been seared on the stove top.

Conclusion

Generally, in the market place today carbon steel cookware, such as with famous brands including DeBuyer or Rosle, is sold uncoated. In order to protect these pans from rust, and to give them a non-stick release, the consumer is advised to season them before use. Seasoning involves heating oil to a high temperature on a steel pan, passed its smoke point. During this process the pores of the steel open and while this is happening the polymerized fat creates a hard, glassy film between and over the steel surface. With this treatment the steel pan is now not only protected from rust, but also conditioned with a non-stick effect.

Although Lotus Rock does use carbon steel, it does not need to be seasoned because on both the interior and exterior of the pan is a thick enamel coating protecting it from oxidation. This coating, just like the polymerized fat of a seasoned pan, provides effective corrosion resistance. However, unlike an uncoated steel pan, a Lotus Rock pan doesn’t give the consumer the hassle of re-seasoning the pan after each use. The thick enamel coating on Lotus Rock is metal utensil safe and is highly durable for long lasting protection from rust.

In addition, a Lotus Rock pan also doesn’t need to be seasoned to create a non-stick release because on top of the thick ceramic interior is a silicon-oxide coating. When oil is added to a Lotus Rock pan it permeates the lipophilic surface of the silicon-oxide coating to create a natural, non-stick effect. A significant advantage of the silicon-oxide crystal coating over the non-stick patina of a seasoned pan is that it is safe to use with acidic ingredients or sauces, so the consumer can use the pan for a greater variety of cooking methods.

March 21, 2025 / arnoldtnn / 0 Comments

Background

Until the 1960s nearly all cookware in most households around the world was either cast iron, copper, or stainless steel with no coating on the cooking surface. This began to change in 1954 when Marc Gregoire, a Frenchman, applied a coating which contained a substance called PTFE on a pan.

The rise of Teflon

The new coating, called Teflon, became a worldwide hit among consumers who wanted a more hassle-free, easy-to-use cookware item. In western society Teflon became a household word, so well-known that it was given as a nickname to politicians who seemed able to survive any disaster with their reputations unblemished – for example Tony Blair was known as ‘Teflon Tony’.

However, the Teflon brand’s credibility (like Tony Blair’s political career) began to suffer in the late 90s when it was found that if the coating was applied under too much heat the PTFE, which provided the non-stick release in the coating, would breakdown and emit toxic fumes which would kill birds and possibly be damaging to human health. There were also complaints that the coating would peel off after extensive use.

The emergence of ceramic coatings

Therefore, in the late 00’s coating manufacturers, such as Greenpan and Whitford, began to develop ceramic coatings, which were seen as a healthier alternative to Teflon because they contained no PTFE. At first ceramic coated pans were a huge success, because not only were they seen as a healthier alternative to PTFE-based coatings, but they also looked very attractive with their cream and white colour.

However, after intensive use by various customers all over the world it was soon discovered that although ceramic coatings didn’t have any health concerns, they were affected by some serious quality control issues. The biggest difficulty with ceramic coatings was that after sustained use the silicone oil inside the coating would dry out and the non-stick effect would become redundant. Customers were therefore paying for cookware utensils with a non-stick release which would not, in some cases, last longer than a year. In addition, it was also discovered that the colour stain and scratch resistance of ceramic coatings was not as good as previously thought.

Stone-finish cookware

Some cookware manufacturers responded to this by producing items with a stone finish. Although these cookware items still contained some PTFE, they at least had a stronger, more durable appearance than lightly coloured ceramic coatings. And yet, although these new coatings did appear to have a stronger construction, the stone finish was misleading, because they were not metal utensil-safe and, like every other non-stick coated cookware, intense use eventually degraded the coating, either wearing it away or reducing the non-stick release.

What next?

So by early 2013 there was a significant gap in the market: consumers wanted a high quality cookware item without possible health concerns (such as those associated with PTFE), a non-stick effect that would last for at least a few years (unlike ceramic coatings), and a pan which didn’t just look scratch-resistant but really was metal utensil-safe.

It is for this reason that the popularity of Lotus Rock cookware has risen exponentially in the last couple of years. As you can see from the table below Lotus Rock has various advantages, all of which either match or exceed the existing competition in the market place.

|

PTFE coating

|

Ceramic coating

|

Stone-finish coating

|

Lotus Rock coating

|

|

Durable non-stick release?

|

Good

|

Poor

|

Good

|

Excellent

|

|

Health issues?

|

Yes

|

None

|

Yes

|

None

|

|

Scratch resistance?

|

Poor

|

Ok

|

Good

|

Excellent

|

Lotus Rock cookware is now sold in all 6 continents of the world, from the USA, to Venezuela, to various European countries such as the UK, Italy and Turkey, to South Africa, Australia and Hong Kong. There are various reasons for this sudden popularity, but one of them is the natural, non-toxic, durable non-stick release.

Why does Lotus Rock have such a unique, long-term, and effective non-stick effect?

All Lotus Rock items contain a thin layer of nano-silica, which is lipophilic (fat-loving). This coating, which rests on top of a thick ceramic layer, is permeable to cooking oil. At the beginning of the cooking process the consumer must add cooking oil which then infiltrates the surface of the cookware.

By permeating the surface of the cookware the oil is able to rest inside the nano-silica, thus creating a natural, long-lasting non-stick release which, unlike all other general coatings, won’t significantly worsen over time. Thus by the simple act of adding oil before cooking the customer creates a physical non-stick surface, perfect for a high-quality cooking experience – similar to cooking on uncoated cast iron, except that with Lotus Rock no re-seasoning is needed, so the customer need not worry about rust.

March 5, 2025 / arnoldtnn / 2 Comments

As explained here, if you discover that the non-stick performance of your Lotus Rock pan has become impaired then there is a procedure to renew it. However, if a Lotus Rock pan is maintained well then this non-stick renewal procedure should only have to be used rarely, if at all.

Generally all cookware sold today can be categorized in 3 ways, these are:

i) Chemical non-stick coated

ii) Stainless steel

iii) Reactive cookware (such as uncoated cast iron, carbon steel, aluminium, and copper)

Lotus Rock is such a unique and highly innovative product precisely because it doesn’t solely fall into any of these categories. Although it does have a non-stick release, Lotus Rock is highly distinctive in the market because the non-stick is PTFE/PFOA free and it doesn’t use sol-gel technology like a general ceramic coating. Also, unlike a chemical non-stick coating, Lotus Rock is metal utensil safe and it has high heat resistance.

Stainless steel of course does have excellent scratch and heat resistance but it does not have as good a heating effect as Lotus Rock for browning and searing, and it needs to use a lot more oil to make the pan’s surface non-stick.